03-TM-0037 REV 13

Page 12 of 24

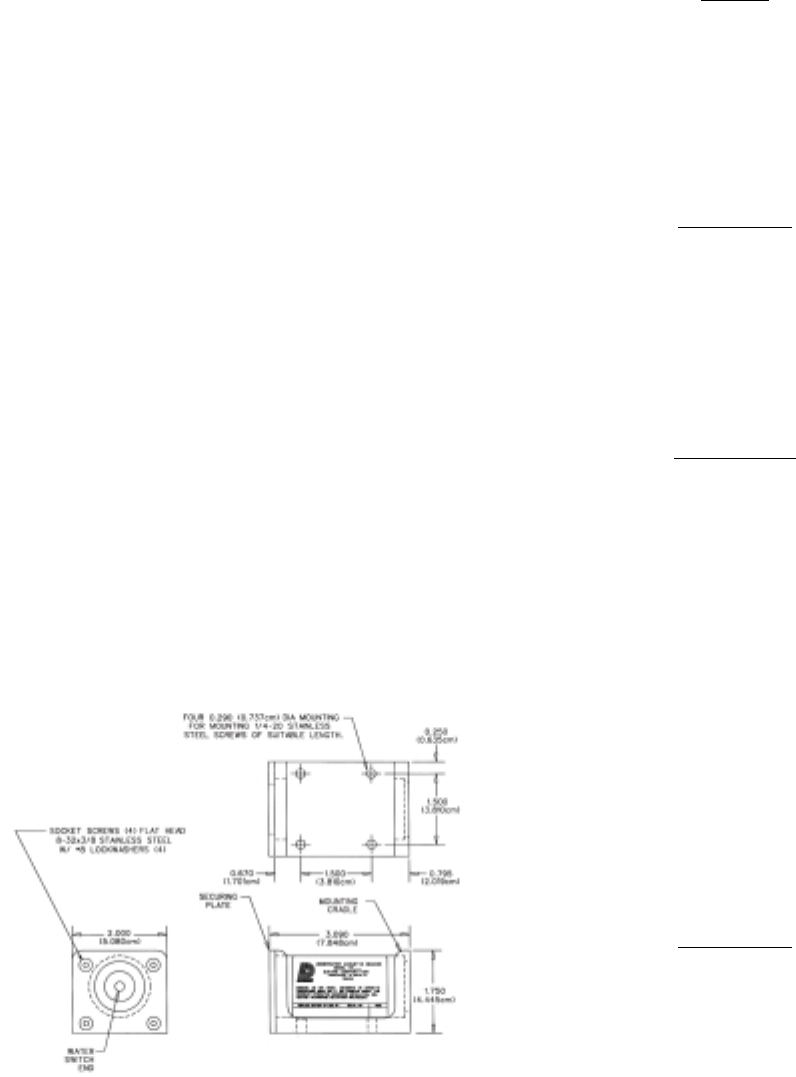

2.8. INSTALLATION PROCEDURES FOR

THE DK130/DK140 AND THE N30A29

SERIES MOUNTING KIT.

2.8.1. GENERAL. Model N30A29 Series

Mounting Kit (Cradle Type) is an aluminum

extrusion with a screw-attached securing plate

that provides rugged mounting and protection of

the beacon within the aircraft. See Figure 9. The

beacon should be mounted horizontally with the

switch end forward, if possible. If vertical

mounting is necessary, switch end must be

mounted downward to prevent accumulation of

dirt, grease and water on the switch end.

2.8.2. CRADLE MOUNTING PROCEDURE.

A. Using Figure 9 as a guide, locate the four

0.290 inch (0.737 cm) diameter holes on 1.500 in

by 1.500 in (3.810 by 3.810 cm) centers. Be sure

access to the securing plate end is available for

future beacon installation and removal. Approxi-

mately 4.5 inches (11.43 cm) clearance should

be allowed for beacon removal.

Figure 9. N30A29 Mounting Kit

Installation Details

CAUTION

WHEN MOUNTING TO THE AIR-

FRAME, CHECK THE OPPOSITE

SIDE OF THE FRAME OR BULK-

HEAD FOR DRILLING CLEAR-

ANCE.

WARNING

USE PROTECTIVE EYE EQUIP-

MENT DURING DRILLING OPERA-

TION.

B. After the four 0.290-inch (0.737 cm) diameter

holes have been located, drill the holes with an

“L” twist drill.

C. Secure the mounting cradle to the aircraft

structure with four 1/4-20 stainless steel screws

and associated washers and nuts (not furnished),

as shown in Figure 9. Alternate mounting with

threaded holes may be employed where structure

does not permit nuts on rear side.

CAUTION

DO NOT ADD ANY UNAPPROVED

STAMP, ETCHING, OR LABEL TO

THE BEACON CASE OR END CAPS.

2.8.3. INSTALLING DK130/DK140 BEACON

INTO N30A29 SERIES MOUNTING KIT.

A. If the securing plate and its attaching hard-

ware are already attached to the main body of the

mounting cradle, remove them.

NOTE

The mounting bracket can be used as a

template to mark for drilling the holes

prior to the installation of the beacon.

Always remove the beacon from the mount

prior to marking or drilling.