03-TM-0037 REV 13

Page 10 of 24

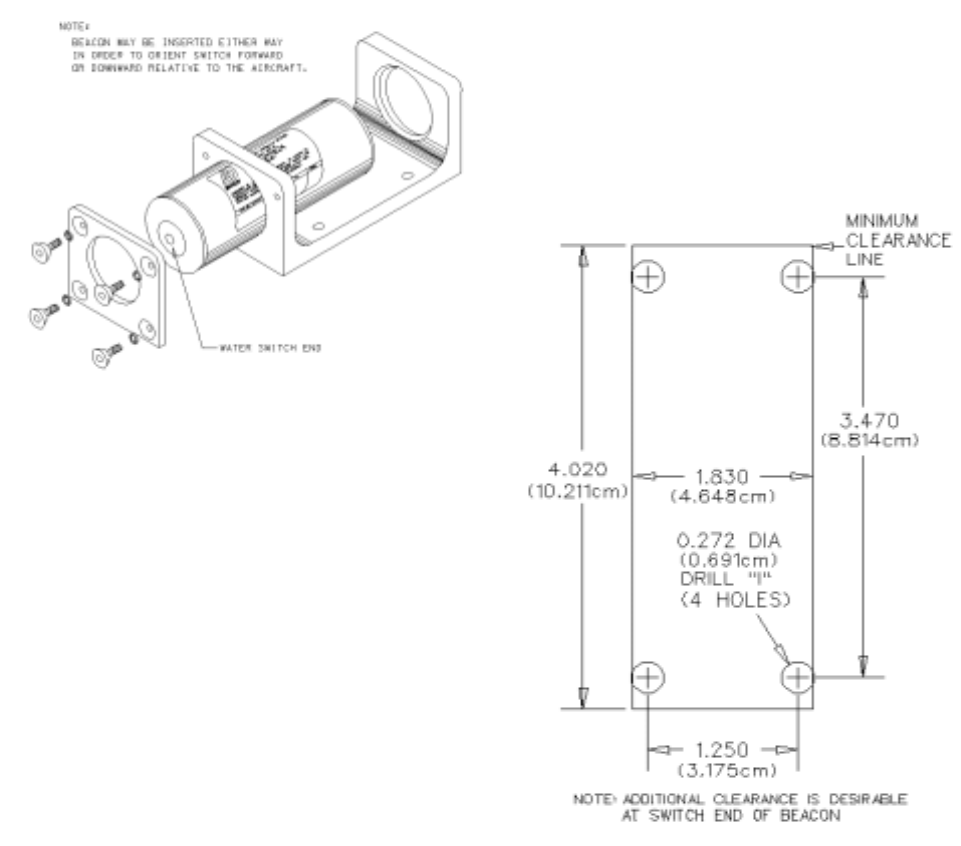

Figure 4. Installation of N30A26

Series Mounting Kit and Beacon

D. Insert the beacon into the mounting cradle

with the water switch facing forward and/or

downward with reference to the aircraft. Rotate

the beacon in the mount so that the beacon

replacement date can be read. See Figure 4.

E. Screw securing plate in place with the set of

furnished screws and washers. Tighten until the

securing plate makes contact with the frame in

the area of the screws, with approximately 15 to

20 inch-pounds torque.

F. Perform the Operational Test outlined in

Section IV.

2.7. INSTALLATION PROCEDURES FOR

THE DK100/DK120 AND THE N30A21A

MOUNTING KIT.

2.7.1. GENERAL. Space limitations sometimes

require the use of the strap-type N30A21A

Mounting Kit. Where a choice exists, horizontal

mounting with switch forward is best. If vertical

mounting is employed, mount switch down to

reduce accumulation of grease, dirt, and water on

the switch end of the beacon.

2.7.2. MOUNTING PROCEDURE

A. Lay out four holes as shown in Figure 5.

Position mounting kit carefully to avoid interfer-

ence with other structures. Observe the clear-

ances required as shown in Figures 5 and 6, and

in established tool and maintenance clearances.

B. Drill the four 0.272 inch (0.691 cm) (“I” drill)

holes in the mounting surface as shown in Figure

5.

Figure 5. Mounting Hole Template

for N30A21A Mounting Kit

C. Test the beacon as outlined in Section IV to

insure operation prior to installation.

D. Slip the retainer straps of the mounting kit

over the ends of the beacon. See Figures 7 and 8.

E. Insert the ends of the retainer straps through

the 0.272 inch (0.691 cm) holes in the mounting

surface. When horizontal mounting is used,

position beacon with switch end forward.

C. Test the beacon as outlined in Section IV to

insure operation prior to installation.