Lotus Service Notes Section EMN

Page 16

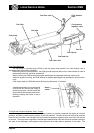

EMN.13 - CAMSHAFT POSITION SENSOR (VVC versions only)

The camshaft position sensor has two functions: i) to provide an engine position reference for the sequen-

tial injection; ii) to measure the actual inlet cam period as controlled by the VVC mechanism. The inductive

type sensor is mounted on the right hand side of the cylinder head and projects into the cam housing to be in

close proximity to a toothed reluctor on the inlet camshaft of no. 2 cylinder.

By interpreting the signals received, the ECM is able to distinguish firing TDC from exhaust TDC, and

initiate the injection sequence on engine start. If, however, the sensor should fail before engine start, the

engine will start and continue to run in grouped fuelling mode (injectors activated in pairs) with a reduced rev.

limit of approx. 5,600 rpm applied to protect the engine from potential damage. If sensor failure occurs whilst

the engine is running, the engine will continue to run in sequential fuelling mode until ignition switch off.

If the ECM detects any faults with cam period measurement during start up and initial running, the ECM

will try and drive (dependent on the cause of the fault) the mechanism to minimum cam period. Engine speed

will be limited to approx. 5,600 rpm, and the idle speed will be raised. If the ECM loses the cam priod signal

during running, the cam period will remain frozen at the last valid period. Engine speed may be limited as low

as 5500 rpm depending on cam period when the fault occured. The idle speed will be raised for the rest of the

journey. Note that a cam period measurement fault will only be recorded by the ECM if the fault is detected at

start-up or during initial running.

When refitting or replacing a cam angle sensor, use a new 'O' ring, and tighten the fixing screw to 6 Nm.

Camshaft position sensor

em221