1-12 2000 cadillac deville

Outer Wheelhouse

Sectioning

Removal Procedure

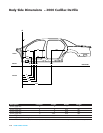

1. Locate horizontal laser-weld line in upper

quarter area (Fig. 1-18).

2. Measure down 25␣ mm (1␣ in) and scribe a cut

line.

3. On the vehicle rocker area, locate and scribe a

vertical cut line in the recommended section

area.

4. Cut panel at scribed locations.

5. Drill out factory welds. Note the number and

location of welds.

6. Remove the damaged panel.

Preparation Of Service Part

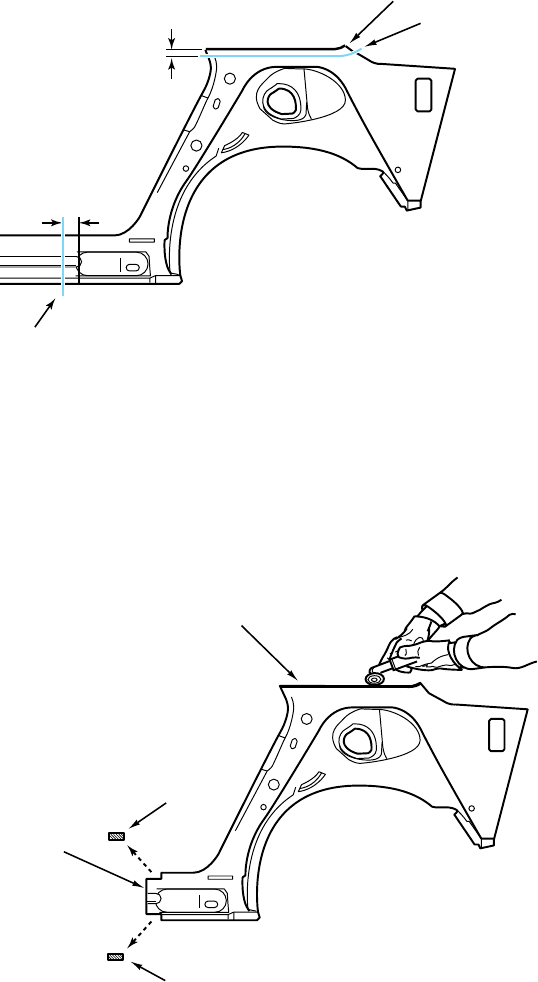

1. Locate laser weld line on service part

(Fig. 1-19).

2. Cut along laser weld line.

3. In specified sectioning location of rocker area,

create a vertical cut line. Allow for a 50␣ mm

(2␣ in) overlap of service part to rocker area on

the vehicle.

4. Cut service part along marked locations.

5. Trim a 20␣ mm x 50␣ mm (7/8 in x 2␣ in) tab at

top and bottom of section area of service part

to allow for a flush fit at pinch welds.

6. Drill plug weld holes in service part as noted

from original panel.

7. Drill 8␣ mm (5/16␣ in) plug weld holes along

section areas 25␣ mm (1␣ in) from edge on

rocker and 13␣ mm (1/2␣ in) from edge in upper

quarter area.

Installation Procedure

1. Install new part and clamp in place.

Check for fit.

IMPORTANT: Prior to refinishing, refer to

the publication GM4901M-D-2000 “GM

Approved Refinish Materials” for

recommended products. Do not combine

paint systems. Refer to manufacturer’s

recommendations.

2. Apply two-part catalyzed primer.

3. Spot blast weld areas.

4. Perform stitch weld, plug weld, grind and

finish as necessary.

5. Use a brushable seam sealer on inside seam.

6. Install all related panels and components.

Fig.␣ 1-19 — 2000 DeVille Outer Wheelhouse

Preparation

Fig.␣ 1-18 — 2000 DeVille Outer Wheelhouse

Removal

25 MM

(1 IN)

MINIMUM

50 MM (2 IN)

CUT

LINE

LASER WELD

CUT LINE

LASER WELD LINE

TRIM

TA B

TRIM

TA B

SECTIONING

AREA