CARBURETOR

6-7

8. Check:

• Jet needle “1”

Bends/wear/damage → Replace.

• Clip groove

Free play/wear → Replace.

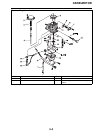

9. Check:

• Main jet “1”

• Pilot jet “2”

• Needle jet “3”

• Needle jet holder “4”

• Starter jet “5”

• Coasting enricher jet (P. A. J. 2) “6”

Bends/damage/wear → Replace.

Obstruction → Clean.

Blow out the jets with compressed air.

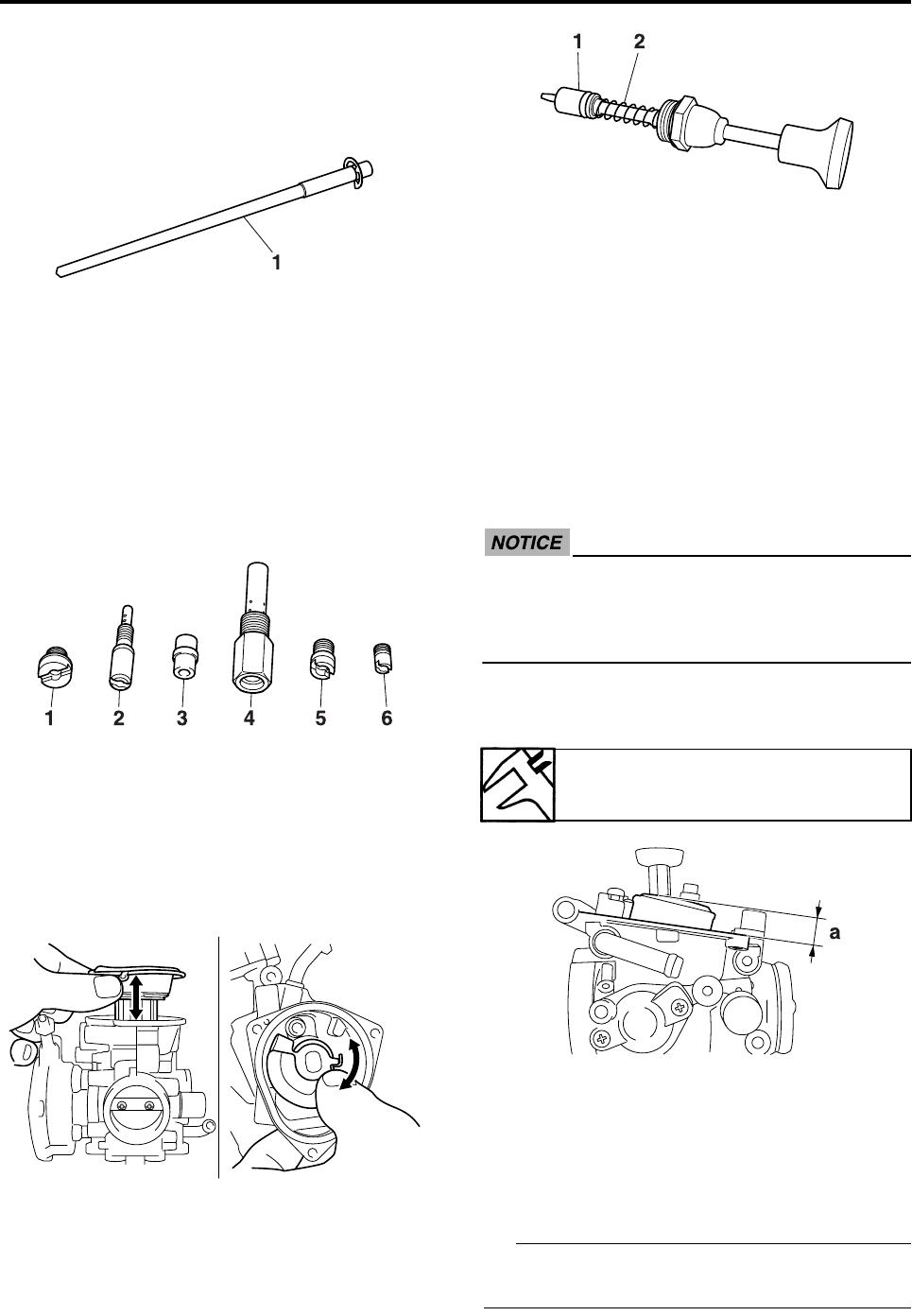

10.Check:

• Piston valve movement

Insert the piston valve into the carburetor

body and move it up and down.

Tightness → Replace the piston valve.

• Throttle valve movement

Sticks → Replace.

11.Check:

• Starter plunger

• Starter plunger spring

Bends/cracks/damage → Replace.

12.Check:

•Hose joints

Cracks/damage → Replace.

13.Check:

• Air vent hose

• Fuel hose

• Drain hose

Cracks/damage/wear → Replace.

Obstruction → Clean.

Blow out the hoses with compressed air.

EAS26800

ASSEMBLING THE CARBURETOR

ECA14110

• Before assembling the carburetor, wash

all of the parts in a petroleum-based sol-

vent.

• Always use a new gasket.

1. Measure:

• Float height “a”

Out of specification → Adjust.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Hold the carburetor in an upside down

position.

b. Measure the distance from the front mating

surface of the float chamber (gasket

removed) to the top of the float.

TIP

The float arm should be resting on the needle

valve, but not compressing it.

Float height

13.0 mm (0.51 in)