59

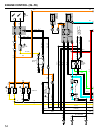

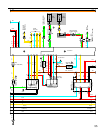

ENGINE CONTROL (2VZ–FE)

THE TCCS SYSTEM UTILIZES A MICROCOMPUTER AND MAINTAINS OVERALL CONTROL OF THE E/G, T/M, ETC. AN OUTLINE OF ENGINE CONTROL IS

GIVEN HERE.

1. INPUT SIGNALS

(1) WATER TEMP. SIGNAL SYSTEM

THE WATER TEMP. SENSOR DETECTS THE E/G COOLANT TEMP. AND HAS A BUILT–IN THERMISTOR WITH A RESISTANCE WHICH VARIES ACCORDING

TO THE WATER TEMP. THUS THE WATER TEMP. IS INPUT IN THE FORM OF A CONTROL SIGNAL TO TERMINAL THW OF THE TCCS ECU.

(2) INTAKE AIR TEMP. SIGNAL SYSTEM

THE INTAKE AIR TEMP. SENSOR IS INSTALLED INSIDE THE AIR FLOW METER AND DETECTS THE INTAKE AIR TEMP., WHICH IS INPUT AS A

CONTROL SIGNAL TO TERMINAL THA OF THE ECU.

(3) OXYGEN SENSOR SIGNAL SYSTEM

THE OXYGEN DENSITY IN THE EXHAUST. EMISSIONS IS DETECTED AND INPUT AS A CONTROL SIGNAL TO TERMINAL OX1 OF THE ECU. TO

MAINTAIN STABLE DETECTION PERFORMANCE BY THE OXYGEN SENSOR, A HEATER IS USED FOR WARMING THE SENSOR. THE HEATER IS

ALSO CONTROLLED BY THE ECU (HT).

(4) RPM SIGNAL SYSTEM

CRANKSHAFT POSITION AND E/G RPM ARE DETECTED BY THE PICK–UP COIL INSTALLED INSIDE THE DISTRIBUTOR. CRANKSHAFT POSITION

IS INPUT AS A CONTROL SIGNAL TO TERMINALS G1 AND G2, OF THE ECU, AND RPM IS INPUT TO TERMINAL NE.

(5) THROTTLE SIGNAL SYSTEM

THE THROTTLE POSITION SENSOR DETECTS THE THROTTLE VALVE OPENING ANGLE, WHICH IS INPUT AS A CONTROL SIGNAL TO TERMINAL

VTA OF THE ECU, OR WHEN THE VALVE IS FULLY CLOSED, TO TERMINAL IDL.

(6) VEHICLE SPEED SIGNAL SYSTEM

THE SPEED SENSOR, INSTALLED INSIDE THE COMBINATION METER, DETECTS THE VEHICLE SPEED AND INPUTS A CONTROL SIGNAL TO

TERMINAL SP1 OF THE ECU.

(7) NEUTRAL START SW SIGNAL SYSTEM (A/T)

THE NEUTRAL START SW DETECTS WHETHER THE SHIFT POSITION IS IN NEUTRAL OR NOT, AND INPUTS A CONTROL SIGNAL TO TERMINAL

NSW OF THE ECU.

(8) A/C SW SIGNAL SYSTEM

THE OPERATING VOLTAGE OF THE A/C MAGNET CLUTCH IS DETECTED AND INPUT IN THE FORM OF A CONTROL SIGNAL TO TERMINAL A/C OF

THE ECU.

(9) BATTERY SIGNAL SYSTEM

VOLTAGE IS CONSTANTLY APPLIED TO TERMINAL BATT OF THE ECU. WHEN THE IGNITION SW IS TURNED TO ON, VOLTAGE FOR ECU

OPERATION IS APPLIED VIA THE EFI MAIN RELAY TO TERMINALS +B AND +B1 OF THE ECU. ALSO, CURRENT FLOWS VIA THE IGN FUSE TO

TERMINAL IGSW OF THE ECU.

(10) INTAKE AIR VOLUME SIGNAL SYSTEM

INTAKE AIR VOLUME IS DETECTED BY THE POTENTIOMETER INSTALLED INSIDE THE AIR FLOW METER AND IS INPUT AS A CONTROL SIGNAL

TO TERMINAL VS OF THE ECU. INSIDE THE AIR FLOW METER THERE IS ALSO A SW FOR FUEL PUMP OPERATION, AND WHEN THE MEASURING

PLATE OPENS (AIR INTAKE OCCURS), THIS SW TURNS ON AND CURRENT FLOWS TO THE FUEL PUMP TO OPERATE IT.

(11) STA SIGNAL SYSTEM

TO CONFIRM THAT THE E/G IS CRANKING, THE VOLTAGE APPLIED TO THE STARTER MOTOR DURING CRANKING IS DETECTED AND IS INPUT

AS A CONTROL SIGNAL TO TERMINAL STA OF THE ECU.

(12) ENGINE KNOCK SIGNAL SYSTEM

ENGINE KNOCKING IS DETECTED BY THE KNOCK SENSOR AND INPUT AS A CONTROL SIGNAL TO TERMINAL KNK OF THE ECU.

2. CONTROL SYSTEM

* EFI (ELECTRONIC FUEL INJECTION) SYSTEM

THE EFI SYSTEM MONITORS THE ENGINE CONDITIONS THROUGH THE SIGNALS EACH SENSOR (INPUT SIGNALS [1] TO [11]) INPUTS TO THE ECU.

BASED ON THIS DATA AND THE PROGRAM MEMORIZED IN THE ECU, THE MOST APPROPRIATE FUEL INJECTION TIMING IS DECIDED AND

CURRENT IS OUTPUT TO TERMINALS #10, #20 AND #30 OF THE ECU. CAUSING THE INJECTORS TO OPERATE (TO INJECT FUEL). IT IS THIS SYSTEM

WHICH, THROUGH THE WORK OF THE ECU, FINELY CONTROLS FUEL INJECTION IN RESPONSE TO DRIVING CONDITIONS.

* ESA (ELECTRONIC SPARK ADVANCE) SYSTEM

THE ESA SYSTEM MONITORS THE ENGINE CONDITIONS USING THE SIGNALS (INPUT SIGNALS [1, 3, 4, 5, 6, 8, 10, 11, 12]) INPUT TO THE ECU FROM

EACH SENSOR. BASED ON THIS DATA AND THE PROGRAM MEMORIZED IN THE ECU, THE MOST APPROPRIATE IGNITION TIMING IS DECIDED AND

CURRENT IS OUTPUT TO TERMINAL IGT OF THE ECU.

THIS OUTPUT CONTROLS THE IGNITER TO PRODUCE THE MOST APPROPRIATE IGNITION TIMING FOR THE DRIVING CONDITIONS.

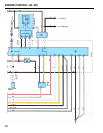

* OXYGEN SENSOR HEATER CONTROL SYSTEM

THE OXYGEN SENSOR HEATER CONTROL SYSTEM TURNS THE HEATER TO ON WHEN THE INTAKE AIR VOLUME IS LOW (TEMP. OF EXHAUST EMISSIONS

LOW), AND WARMS UP THE OXYGEN SENSOR TO IMPROVE DETECTION PERFORMANCE OF THE SENSOR. THE ECU EVALUATES THE SIGNALS FROM

EACH SENSOR (INPUT SIGNALS [1, 4, 9, 10, 11]), CURRENT IS OUTPUT TO TERMINAL HT AND CONTROLS THE HEATER.

* ISC (IDLE SPEED CONTROL) SYSTEM

THE ISC SYSTEM (STEP MOTOR TYPE) INCREASES THE RPM AND PROVIDES IDLING STABILITY FOR FAST IDLE–UP WHEN THE E/G IS COLD AND

WHEN THE IDLE SPEED HAS DROPPED DUE TO ELECTRICAL LOAD, ETC. THE ECU EVALUATES THE SIGNALS FROM EACH SENSOR (INPUT

SIGNALS [1, 4 TO 8, 11]), OUTPUTS CURRENT TO TERMINALS ISC1 ISC2, ISC3 AND ISC4, AND CONTROLS THE ISC VALVE.

* FUEL PRESSURE–UP SYSTEM

THE FUEL PRESSURE UP SYSTEM CAUSES THE VSV (FOR FUEL PRESSURE UP) TO COME ON FOR HIGH TEMP. STARTS AND IMMEDIATELY AFTER

STARTING IN ORDER TO INCREASE THE FUEL PRESSURE, IMPROVE STARTABILITY AT HIGH TEMPERATURES AND PROVIDE STABLE IDLING. THE

ECU EVALUATES THE INPUT SIGNALS FROM EACH SENSOR (1, 2, 4 AND 12), OUTPUTS CURRENT TO TERMINAL FPU AND CONTROLS THE VSV.

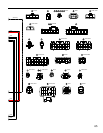

SYSTEM OUTLINE