171

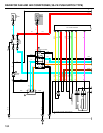

RADIATOR FAN AND AIR CONDITIONER (2VZ–FE)

1. RECIRC/FRESH CONTROL SERVO MOTOR OPERATION (FOR PUSH SWITCH TYPE)

(SWITCHING FROM FRESH TO RECIRC)

WITH THE IGNITION SW ON, CURRENT FROM THE GAUGE FUSE FLOWS TO TERMINAL 1 OF THE SERVO MOTOR. WHEN THE

RECIRC SW IS TURNED ON, THE CURRENT FLOWS FROM SERVO MOTOR → TERMINAL 2 → TERMINAL I2 OF THE HEATER

CONTROL ASSEMBLY → TERMINAL I17 → GROUND, THE MOTOR ROTATES AND THE DAMPER MOVES TO THE RECIRC SIDE. WHEN

IT IS IN THE RECIRC POSITION, THE CIRCUIT IS CUT INSIDE THE SERVO MOTOR AND THE DAMPER STOPS IN THAT POSITION.

WHEN THE CIRCUIT FOR THE INDICATOR LIGHT, CURRENT FLOWS FROM THE GAUGE FUSE → TERMINAL I7 OF THE HEATER

CONTROL ASSEMBLY → INDICATOR LIGHT → TERMINAL I17 → GROUND AND THE INDICATOR LIGHT CONTINUES TO LIGHT UP

WHILE THE RECIRC SW IS ON.

(SWITCHING FROM RECIRC TO FRESH)

WHEN THE IGNITION IS ON AND THE FRESH SW IS TURNED ON, CURRENT FLOWS FROM TERMINAL 3 OF THE SERVO MOTOR →

TERMINAL I10 OF THE HEATER CONTROL ASSEMBLY → TERMINAL I17 → GROUND, THE MOTOR ROTATES AND THE DAMPER

MOVES TO THE FRESH SIDE. WHEN THE DAMPER IS IN THE FRESH POSITION, THE CIRCUIT IS CUT INSIDE THE SERVO MOTOR

AND THE DAMPER STOPS IN THAT POSITION.

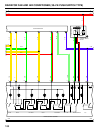

2. OPERATION OF THE AIR VENT MODE CONTROL SERVO MOTOR (FOR PUSH SWITCH TYPE)

(SWITCHING FROM FACE TO BI–LEVEL)

WHEN THE BI–LEVEL SW IS TURNED ON WITH THE DAMPER IN THE FACE POSITION, A SIGNAL THAT THE CIRCUIT IS GROUNDED IS

OUTPUT FROM TERMINAL I12 OF THE HEATER CONTROL ASSEMBLY → TERMINAL 6 OF THE SERVO MOTOR → TERMINAL D11 OF

THE SYSTEM AMPLIFIER. (AT THIS TIME, THE CURRENT FLOWING THROUGH TERMINAL I7 OF THE HEATER CONTROL ASSEMBLY

FLOWS THROUGH TERMINAL I17 → GROUND, CAUSING THE INDICATOR LIGHT TO LIGHT UP). AT THE SAME TIME, THE SIGNAL FOR

WHEN THE CIRCUIT IS NOT GROUNDED IS INPUT TO TERMINAL D10 OF THE AMPLIFIER. THESE 2 SIGNALS CAUSE THE AMPLIFIER

TO OPERATE AND CURRENT FLOWS FROM TERMINAL D5 OF THE AMPLIFIER → SERVO MOTOR → TERMINAL D4 → GROUND,

WHICH ROTATES THE SERVO MOTOR, CAUSING THE DAMPER TO MOVE TO THE BI–LEVEL POSITION.

WHEN THE DAMPER COMES TO THE BI–LEVEL POSITION, A SIGNAL THAT THE GROUND CIRCUIT IS CUT IS INPUT TO TERMINAL D11

OF THE AMPLIFIER, AND AMPLIFIER OPERATION CAUSES THE SERVO MOTOR TO STOP ROTATING AND THE DAMPER TO STAY IN

POSITION.

(SWITCHING TO OTHER MODE POSITIONS)

WHEN SWITCHING THE DAMPER FROM FACE TOWARDS DEF, AS EXPLAINED BEFORE, A GROUND SIGNAL IS INPUT TO TERMINAL

D11 OF THE AMPLIFIER AND A NON–GROUND SIGNAL IS INPUT TO TERMINAL D10 SO THAT CURRENT FLOWS FROM TERMINAL D5

→ SERVO MOTOR → TERMINAL D4, MOVING THE DAMPER TO THE DESIRED POSITION.

WHEN SWITCHING THE DAMPER IN THE OPPOSITE DIRECTION FROM DEF TOWARDS FACE, A GROUND SIGNAL IS INPUT TO

TERMINAL D10 OF THE AMPLIFIER AND A NON–GROUND SIGNAL IS INPUT TO TERMINAL D11 SO THAT THE CURRENT FLOWS FROM

TERMINAL D4 → SERVO MOTOR → TERMINAL D5, CAUSING THE SERVO MOTOR TO ROTATE IN REVERSE AND MOVING THE

DAMPER TO THE DESIRED POSITION.

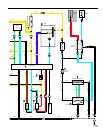

3. OPERATION OF THE AIR MIX CONTROL SERVO MOTOR (FOR PUSH SWITCH TYPE)

(SWITCHING FROM WARM TO COOL)

WHEN THE TEMPERATURE CONTROL KNOB IS SWITCHED FROM WARM POSITION TO COOL POSITION, THE RESISTANCE INSIDE

THE HEATER CONTROL ASSEMBLY BECOMES GREATER THAN THE RESISTANCE INSIDE THE SERVO MOTOR. THE SIGNAL AT THIS

TIME IS INPUT TO THE SYSTEM AMPLIFIER, CAUSING THE AMPLIFIER TO OPERATE. CURRENT FLOWS FROM TERMINAL D8 OF THE

AMPLIFIER → SERVO MOTOR → TERMINAL D9 → GROUND, CHANGING THE DAMPER FROM WARM TO COOL POSITION. WHEN THE

RESPECTIVE RESISTANCES ARE THE SAME VALVE, THE SERVO MOTOR STOP.

(SWITCHING FROM COOL TO WARM)

WHEN THE TEMPERATURE CONTROL KNOB IS SWITCHED FROM COOL POSITION TO WARM POSITION, THE RESISTANCE INSIDE

THE HEATER CONTROL ASSEMBLY BECOMES LESS THAN THE RESISTANCE INSIDE THE SERVO MOTOR. THE SIGNAL AT THIS TIME

IS INPUT TO THE SYSTEM AMPLIFIER, CAUSING THE AMPLIFIER TO OPERATE. CURRENT FLOWS FROM TERMINAL D9 OF THE

AMPLIFIER → SERVO MOTOR → TERMINAL D8 → GROUND, CHANGING THE DAMPER FROM COOL TO WARM POSITION. WHEN THE

RESPECTIVE RESISTANCES ARE THE SAME VALVE, THE SERVO MOTOR STOPS.

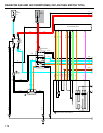

4. RADIATOR FAN AND CONDENSER FAN OPERATION

WHEN THE IGNITION SW IS ON, TURNING THE ENGINE MAIN RELAY TO ON CAUSES CURRENT TO FLOW TO THE RAD FAN FUSE

AND THE CDS FAN FUSE.

* LOW SPEED OPERATION

OPERATION OF THE A/C CONDENSER FAN CONTROL AMPLIFIER TURNS RADIATOR FAN RELAY NO. 1 AND A/C FAN RELAY NO. 2

AND NO. 3 TO ON, AND CURRENT FROM THE CDS FAN FUSE FLOWS IN SERIES FROM THE CONDENSER FAN MOTOR → TERMINAL

1 OF THE A/C FAN RELAY NO. 2 → TERMINAL 4 → TERMINAL 2 OF A/C FAN RELAY NO. 3 → TERMINAL 4 → RADIATOR FAN MOTOR →

GROUND, CAUSING EACH FAN TO ROTATE AT LOW SPEED. [THIS IS WHEN THE WATER TEMP. IS APPROX. 85° TO 90°C (185° TO

194°F).]

* HIGH SPEED OPERATION

OPERATION OF THE A/C CONDENSER FAN AMPLIFIER AND HIGH PRESSURE SW CAUSES CURRENT TO THE COIL SIDE OF

RADIATOR FAN RELAY NO. 1 AND A/C FAN RELAY NO. 2 TO BE CUT (BOTH RELAYS OFF). ACCORDINGLY, CURRENT FROM THE RAD

FAN FUSE FLOWS FROM TERMINAL 4 OF RADIATOR FAN RELAY NO. 1 → TERMINAL 3 → RADIATOR FAN MOTOR → GROUND, AND

CURRENT FROM THE CDS FAN FUSE FLOWS FROM THE CONDENSER FAN MOTOR → TERMINAL 1 OF A/C FAN RELAY NO. 2 →

TERMINAL 3 → GROUND. THIS PARALLEL CURRENT FLOW TO BOTH MOTORS CAUSES BOTH FANS TO ROTATE AT HIGH SPEED.

[THIS IS WHEN THE WATER TEMP. IS APPROX. 90°C (194°F) OR MORE WITH THE MAGNET CLUTCH OFF, OR ELSE WITH THE

MAGNET CLUTCH ON AND THE REFRIGERANT PRESSURE AT 15.5 KG/CM

2

(220 PSI, 1520 KPS) OR MORE.]

SYSTEM OUTLINE