- 16 -

6F8A0883

4.1 Notes on Selecting the Installation Location

1. Avoid places within the immediate proximity of equipment producing electrical interference (such as

motors, transformers, radio transmitters, electrolytic cells, or other equipment causing

electromagnetic or electrostatic interference).

2. Avoid places where excessive pipe vibration occurs.

3. Avoid places where fluid is pumped in a pulsating manner

4. Avoid places where there is direct sunlight. If this is unavoidable, use an appropriate shade

5. Avoid places where corrosive atmospheres or high humidity conditions obtain.

6. Avoid places where there may be limited access such as pipes installed next to high ceilings or

constricted areas where clearance for installation or maintenance work is not provided.

7. Design piping so that the detector pipe is always filled with fluid, whether the fluid is flowing or not.

8. The detector has no adjustable piping mechanism. Install an adjustable short pipe where needed.

9. Chemical injections should be conducted on the downstream side of the flowmeter.

10. The maximum length of the cable that connects the detector and converter is 300m. Select the

converter installation location so that the distance between the detector and converter dose not exceed

300m.

4.2 Mounting Procedure

4.2.1 Pipe checks

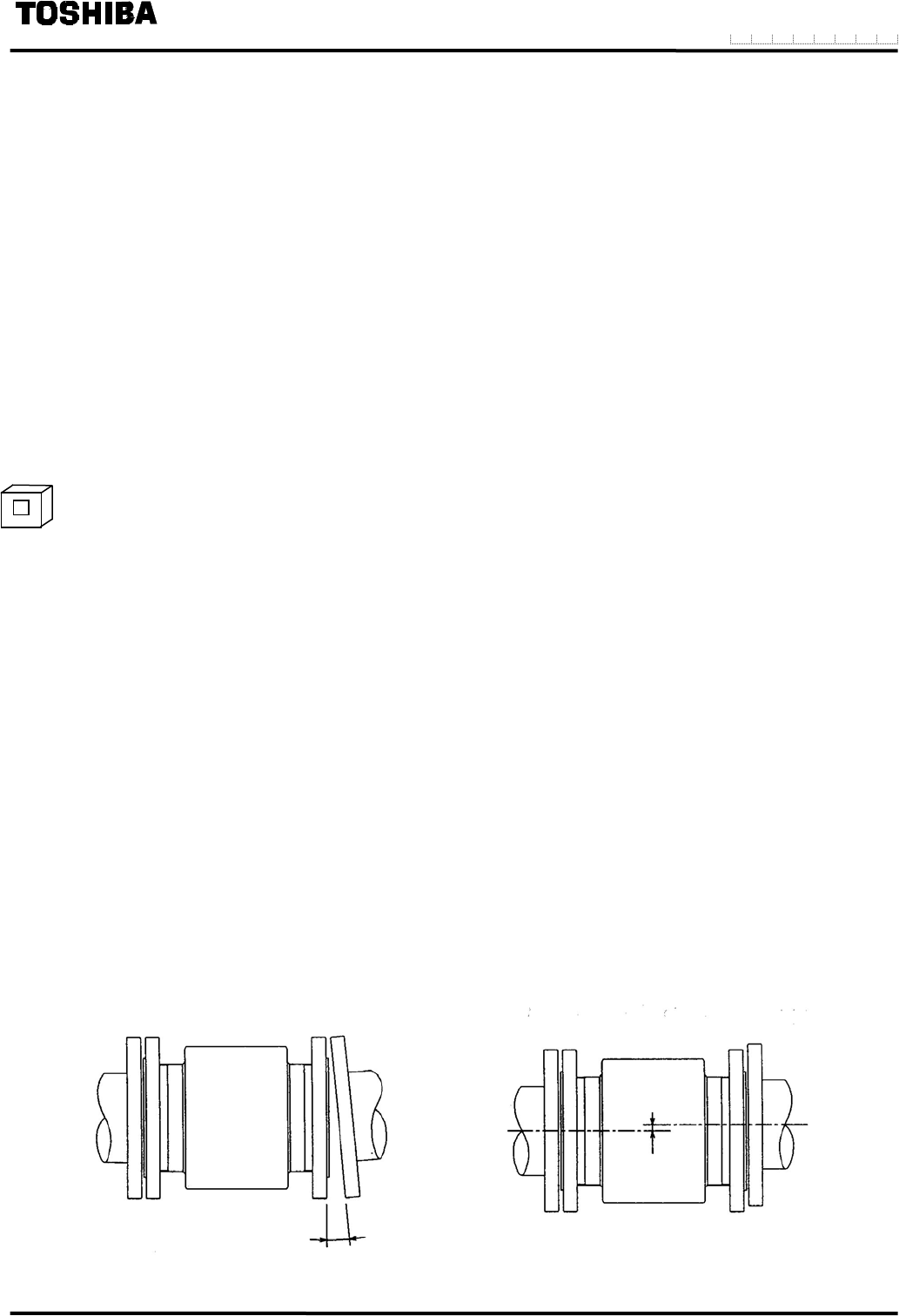

(1) Before installing pipes, check for any leaning, misplacement or eccentricity as illustrated in Figure 4.1.

An attempt to unreasonably connect pipes that are inclined may lead to a detector breakdown or fluid

leakage. Connecting pipes in an eccentric state may also cause wears and tear of linings and grounding

rings, as well as measurement errors.

Before installing pipes, make sure to flush the interior of the pipes to remove deposited material.

(a) Pipe leaning (b) Pipe axis misplacement (or eccentricity)

Figure 4.1 Pipe leaning and axis misplacement

Separate

Inclination

Eccentricity