5-33

SERVICE AND APPEARANCE CARE

78J00-03E

The TPMS system is ready for the sen-

sor matching process to begin.

5) Start with the driver side front tire.

6) Remove the valve cap from the tire’s

valve stem. Activate the TPMS sensor

by increasing or decreasing the tire’s

air pressure for five seconds, or until a

horn chirp sounds. The horn chirp,

which may take up to 30 seconds to

sound, confirms that the sensor identifi-

cation code has been matched to the

tire/wheel position. To decrease the

tire’s air-pressure use the pointed end

of the valve cap, a pencil-style air pres-

sure gage, or a key.

7) Proceed to the passenger side front

tire, and repeat the procedure in Step 6.

8) Proceed to the passenger side rear tire,

and repeat the procedure in Step 6.

9) Proceed to the driver side rear tire, and

repeat the procedure in Step 6.

10)After hearing the confirming horn chirp

for the driver side rear tire, the tire

learning process ends. Turn the ignition

switch to LOCK.

11)Set all four tires to the recommended

air pressure level as indicated on the

tire and loading information label.

12)Put the valve caps back on the valve

stems.

Federal Communications Commission

(FCC) and Industry and Science Canada

The Tire Pressure Monitor System (TPMS)

operates on a radio frequency and com-

plies with Part 15 of the FCC Rules. Oper-

ation is subject to the following two

conditions:

1) This device may not cause harmful

interference.

2) This device must accept any interfer-

ence received, including interference

that may cause undesired operation.

The Tire Pressure Monitor System (TPMS)

operates on a radio frequency and com-

plies with RSS-210 of Industry and Sci-

ence Canada. Operation is subject to the

following two conditions:

1) This device may not cause interfer-

ence.

2) This device must accept any interfer-

ence received, including interference

that may cause undesired operation of

the device.

Changes or modifications to this system by

other than an authorized service facility

could void authorization to use this equip-

ment.

Tire Inspection and Rotation

Tires should be rotated every 5000 to 8000

miles (8000 to 13000 km).

Any time you notice unusual wear, rotate

your tires as soon as possible and check

wheel alignment. Also check for damaged

tires or wheels. Refer to “When It Is Time

for New Tires” and “Wheel Replacement”

in this section for more information.

The purpose of regular rotation is to

achieve more uniform wear for all tires on

the vehicle. The first rotation is the most

important. Refer to “Scheduled Mainte-

nance” in “Maintenance Schedule” in the

“Maintenance Schedule” section for sched-

uled rotation intervals.

811106

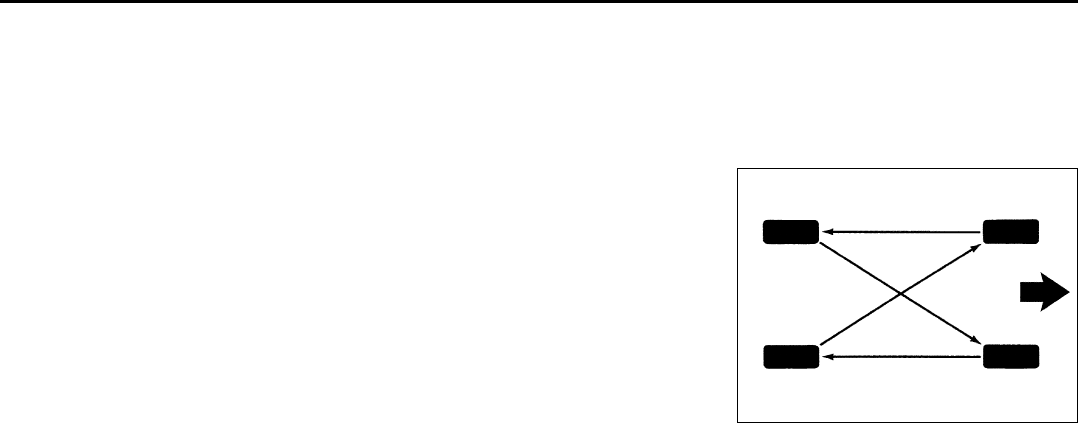

When rotating your tires, always use the

correct rotation pattern shown here.

Do not include the compact spare tire in

your tire rotation.

After the tires have been rotated, adjust

the front and rear inflation pressures as

shown on the Tire and Loading Information

label. Refer to “Inflation -Tire Pressure” in

this section and “Loading Your Vehicle” in

“Your Driving, the Road, and Your Vehicle”

in the “Driving Your Vehicle” section.