3. STOPPING

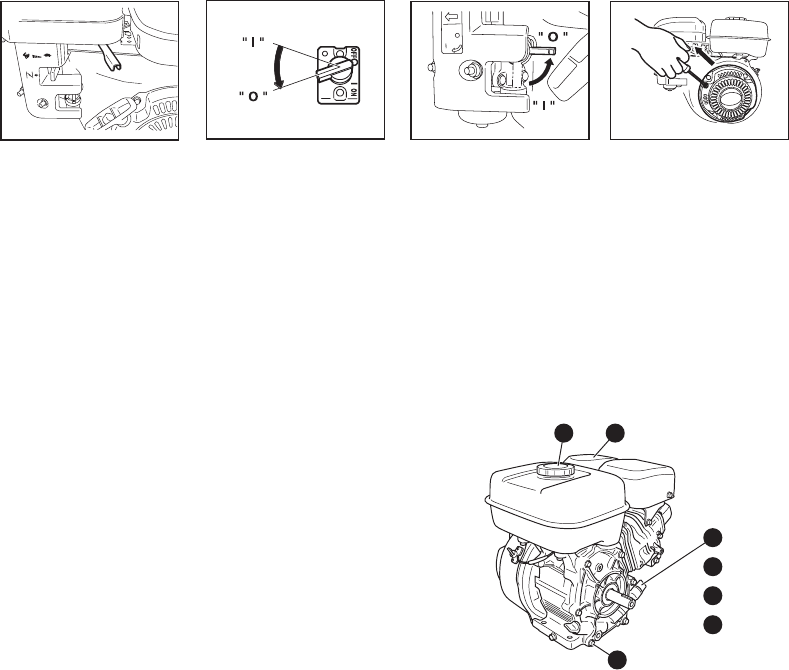

1) Set the speed control lever at the low speed position and allow the engine to run at low speed for 1 or 2 minutes before

stopping.

2) Turn the STOP SWITCH counterclockwise to the “OFF” (O) position.

3) Close the fuel valve

4) Pull the starter handle slowly and return the handle to it original position when resistance is felt. This operation is

necessary to prevent outside moist air from intruding into the combustion chamber.

* STOPPING THE ENGINE WITH THE FUEL VALVE

Close the fuel valve and wait for awhile until the engine stops. Avoid to let the fuel remain in the carburetor over long periods,

or the passages of the carburetor may become clogged with impurities, and malfunction may result.

5. MAINTENANCE

MAINTENANCE, REPLACEMENT, OR REPAIR OF THE EMISSION CONTROL DEVICES AND SYSTEMS MAY BE PER-

FORMED BY ANY NON ROAD ENGINE REPAIR ESTABLISHMENT OR INDIVIDUAL.

1. DAILY INSPECTION

Before running the engine, check the following service items.

• Loose or broken bolts and nuts

• Clean air cleaner element

• Enough clean engine oil

• Leakage of gasoline and engine oil

• Enough gasoline

• Safe surroundings

• Excessive vibration, noise

2. PERIODIC INSPECTION

Periodic maintenance is vital to the safe and efcient operation of your engine.

Check the table for periodic maintenance intervals.

IT IS ALSO NECESSARY FOR THE USER OF THIS ENGINE TO CONDUCT THE MAINTENANCE AND ADJUSTMENTS ON

THE EMISSION-RELATED PARTS LISTED BELOW TO KEEP THE EMISSION CONTROL SYSTEM EFFECTIVE.