42

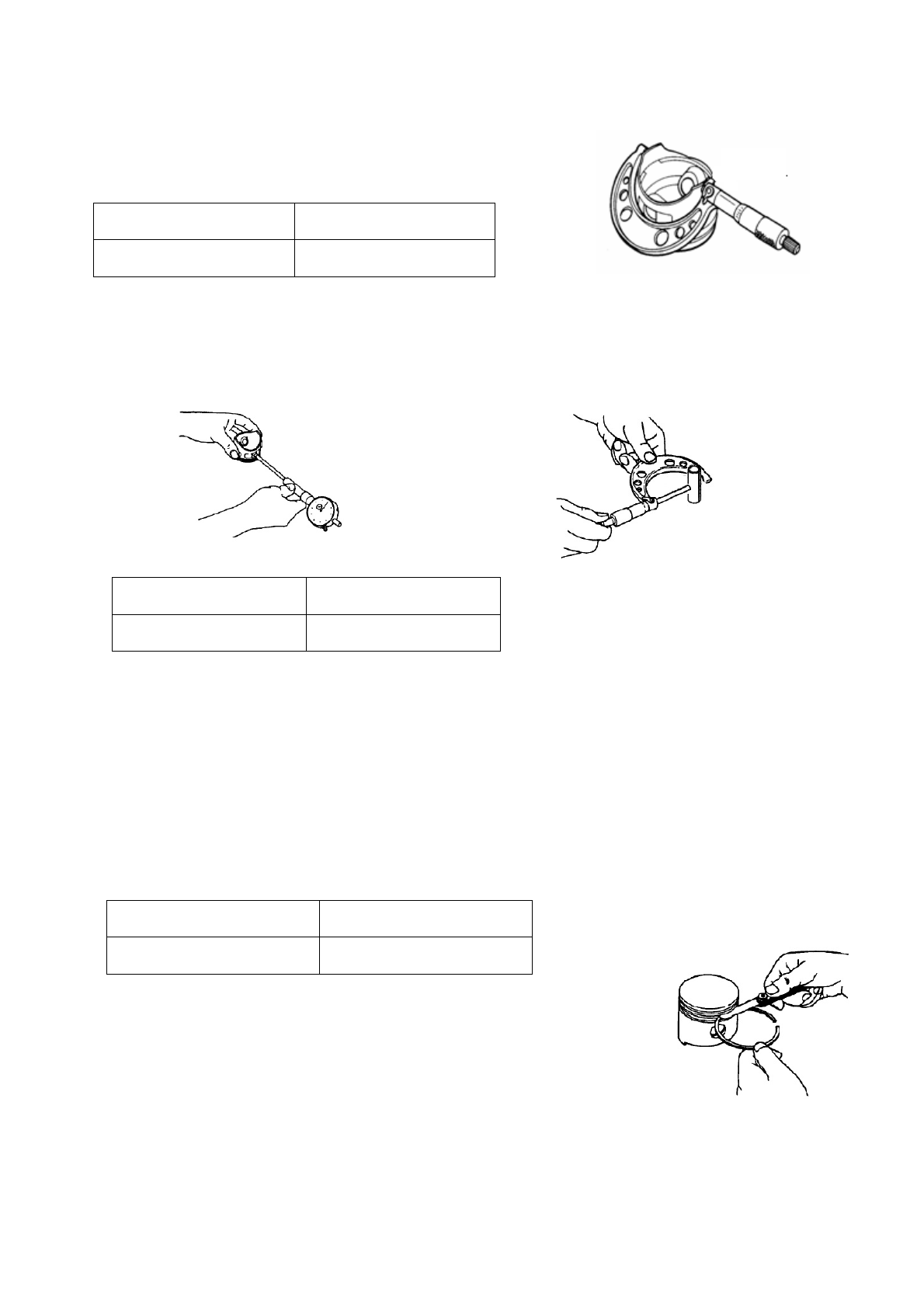

Piston skirt O.D.

Measure the piston skirt O.D. with outside micrometer, if out of the

service limit, replace it.

b) Piston pin bore to piston clearance

Separately measure the piston pin bore I.D and O.D. with inside micrometer and outside micrometer. Then

calculate clearance by measuring results.

c) Piston-cylinder clearance

Difference between the diameter of cylinder maximum and piston skirt should be considered as

piston-cylinder clearance.

Check with piston converting in the cylinder, and inserting feeler between piston skirt bearing face and

wall, then pull the feeler out, if feeling resistance and smoothly out, the thickness of the feeler shall be

considered as piston-cylinder clearance.

NOTICE: This clearance must be checked before and after repairing.

d) Piston ring side clearance

. Check with placing each ring into each-self groove.

. The piston ring should be freely turned without loosening and sticking.

. Then measure with inserting feeler into clearance of the ring between groove

upper and lower face.

Standard Service limit

67.971-67.989mm 67.850mm

Standard Service limit

0.006-0.018mm 0.060mm

Standard Service limit

0.011-0.049mm 0.120mm