13

3-6 Valve clearance adjustment

Keep the clearance between engine valve rod end and driving parts for avoiding heat expanding and cold shrinking to

effect engine performance. If the valve clearance is too big, it can result in exhausting unsmooth, effecting engine

performance and increasing engine noise (valve abnormal); if the valve clearance is too small, the valve will close untight

to make the engine operating abnormal. After operating one year or 300hrs, check and adjust the valve.

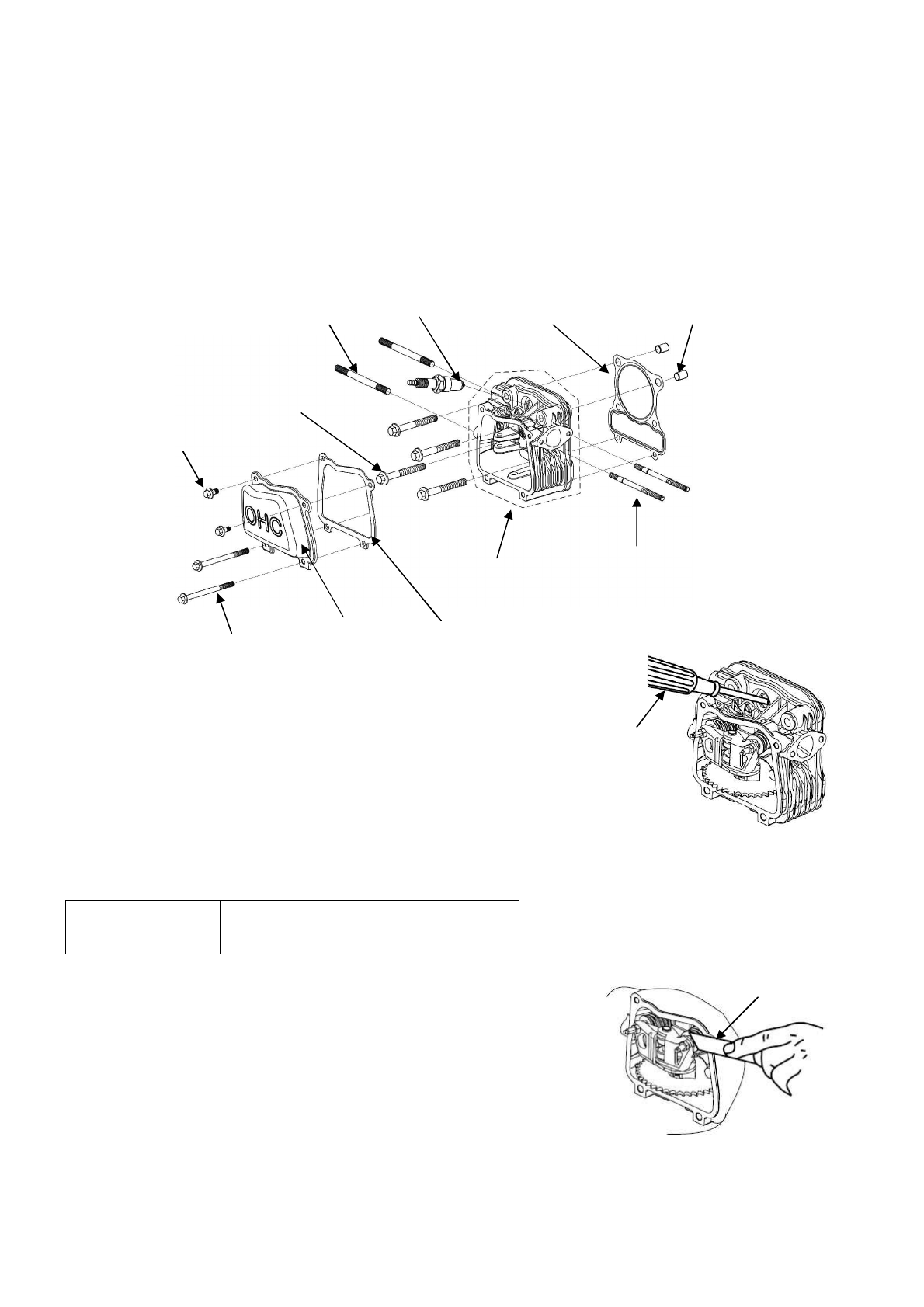

(1) Dismount the spark plug cap, spark plug, cylinder head cover bolt, cylinder head cover and gasket in order.

CAUTION: After the cylinder head cover is removed, engine oil may flow. Be sure to wipe up any flowed oil.

(2) Lightly pull the starting rope and set the piston at top dead center

of the compression stroke (insert screwdriver into the hole of the

spark plug to check the height of piston.)

(3) Measure the valve clearance: Insert the feeler into the clearance

to measure clearance.

Adjust if the valve clearance is out of

the service limit.

CAUTION:

Measure the valve clearance in the cold engine state.

(4)If adjustment is necessary, proceed as follows:

a. Hold valve adjusting bolt with tongs and loosen the valve lock nut.

b. Turn valve adjusting bolt to obtain the specified clearance.

c. Fix the valve adjusting bolt with tongs, and then fix the valve lock nut with spanner.

Valve clearance

IN:0.10-0.15mm

EX:0.15-0.20mm

Dowel Φ10×14

Cylinder head gasket

Stud M6×102

Stud M6×109

Spark plug

Cylinder head assy.

Bolt

Cover gasket

Head cover

Bolt M6×80

Bolt M6×12

Screwdriver

Feeler

Gauge