35

Correct

Incorrect

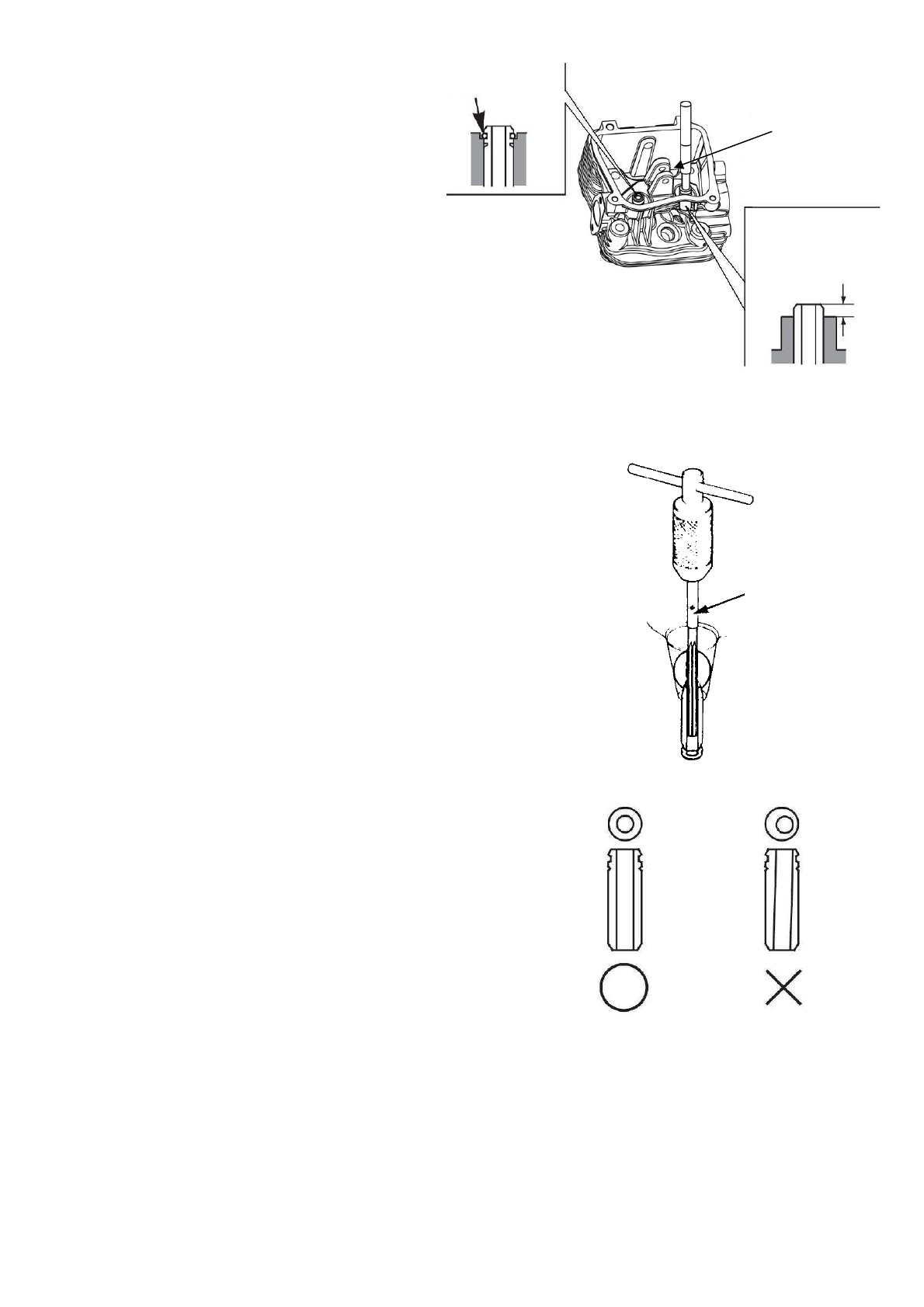

c) Install the new valve guides from the

valve spring side of the cylinder head.

Exhaust side: Drive the exhaust valve guide

until the clip is fully seated (as shown as

fig.)

Intake side: Drive the intake valve guide to

the specified height (measured from the top

of the valve guide to the cylinder cover as

shown as fig.)

d) After installation, inspect the valve guide for damage, if damaged,

please replace.

Reamer:

For best results, be sure the cylinder head is at room

temperature before reaming valve guides.

Coat the reamer and valve guide with cutting oil. Rotate the

reamer clockwise through the valve guide for the full length

of the reamer. Continue to rotate the reamer clockwise while

removing it from the valve guide.

Tools:Valve guide reamer

a) Thoroughly clean the cylinder head to remove

any cutting residue.

b) Check the valve guide bore, it should be

straight, round and centered in the valve guide, insert

the valve and check operation. If the valve does not

operate smoothly, the guide may have been bent

during installation. Replace the valve guide if it is

bent or damaged.

c) Check the valve stem-to-guide clearance

d) The valve stem-to-guide clearance:The valve guide bore detract the valve stem outside

diameter to get the clearance between the valve guide and valve stem.

Valve guide

Installation

height

1MM

Clip

Valve guide driver

Exhaust side

Intake side

Valve

guide

reamer