ENGINE AND PERIPHERALS

Overhauling the engine

10

10-89

CHECKING PISTON PROTRUSION

Clean the piston heads.

Turn the crankshaft once clockwise at the timing end

to bring piston n˚ 1 near to top dead centre.

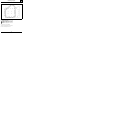

Place tool Mot. 252-01 on the piston.

Place tool Mot. 251-01 fitted with a gauge on the thrust

plate Mot. 252-01, the dial gauge measuring pin being

in contact with the cylinder block, and look for the TDC

of the piston (turn the crankshaft clockwise at the

timing end).

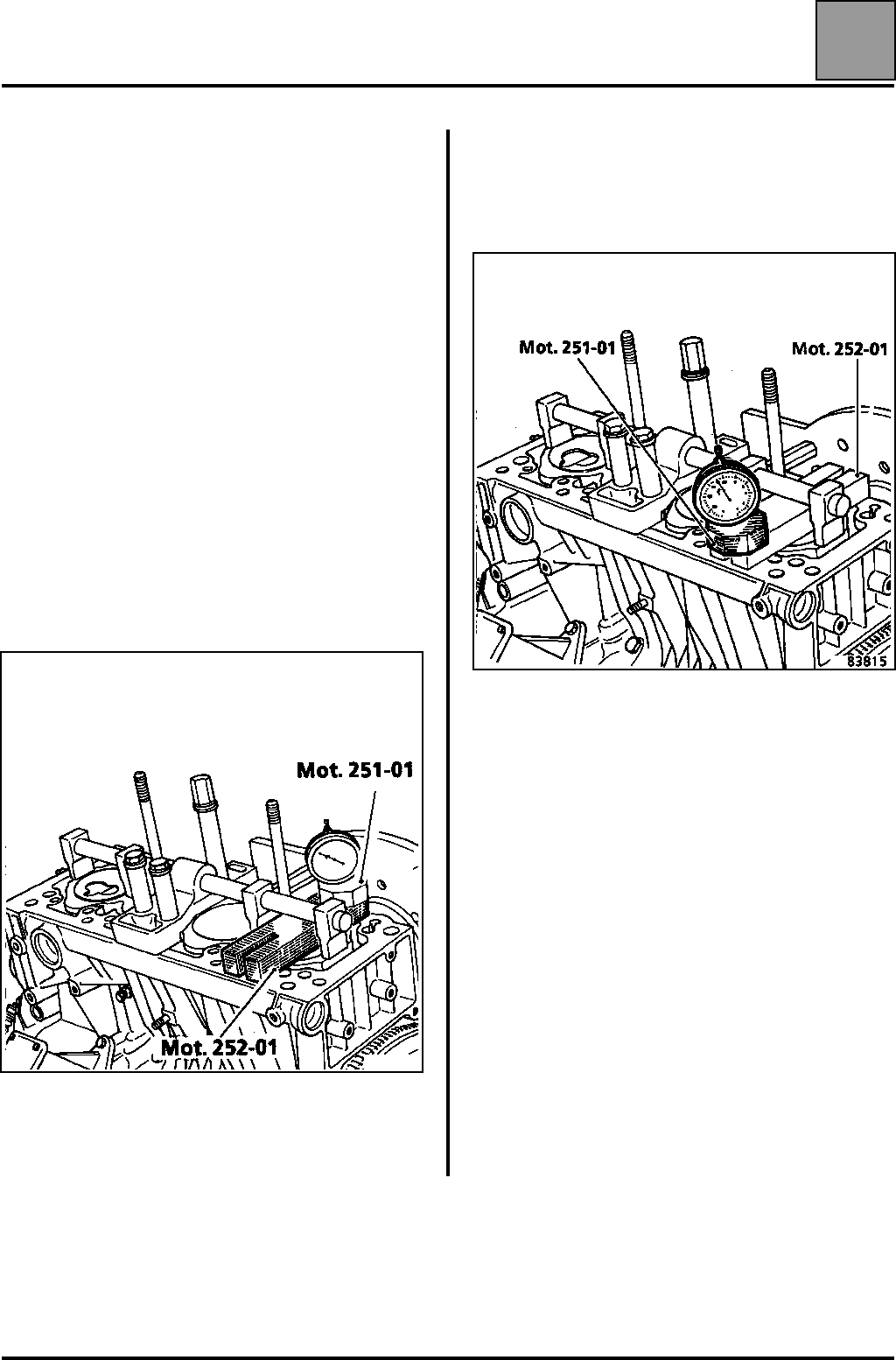

Without putting pressure on the tools or the piston,

to avoid tilting of the piston during measurement,

measure the protrusion when the piston is in position

1, then in position 2 and calculate the average of the

two measurements.

Example:

Protrusion in position 1: 0.83 mm.

Position 1

Example:

Protrusion in position 2: 1.09 mm.

Position 2

Calculate the average piston protrusion:

(083 + 1.09): 2 = 0.96 mm

Carry out this procedure for the other pistons (look for

the TDC by turning the crankshaft clockwise at the

timing end, do not put pressure on tools Mot. 251-01,

and Mot. 252-01 or on the piston).

ONLY CONSIDER THE DIMENSIONS OF THE

PISTON WITH THE GREATEST PROTRUSION

For a protrusion:

– less than 0.96 mm use a cylinder head gasket

1.6 mm thick, marked with 1.6 or 1 hole,

– between 0.96 and 1.04 mm, use a cylinder head

gasket 1.7 mm thick, without a stamped mark or

a hole,

– more than 1.04 mm use a cylinder head gasket

1.8 mm thick, marked with 1.8 or 2 holes.

83814R

83815R