99

MAINTENANCE

Track Maintenance

Track Tensio n

Track adjustment is critical for proper handling. Always maintain

correct tension and alignment. Tension adjustments should be made

only after the track is warmed up and limber.

1. Turn the machine off.

2. Lift the rear of the machine and safely support it off the ground.

3. Place the recommended weight or downward pressure on the track

at the specified d istance (see chart below) ahead o f the center of the

rear idler wheel. NOTE: Measure at the point where the weight is

hanging.

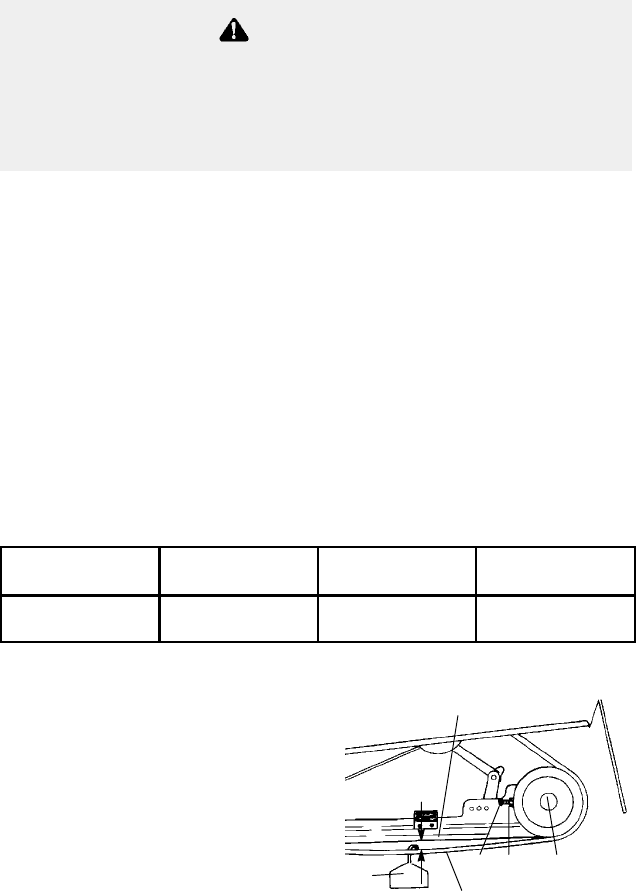

4. Check for specified slack between the wear surface of the track clip

and the plastic Hi-fax (C).

Track Tension Data

Suspension Weight Measurement

Location

Measurement

Edge 136” 10 lbs. (4.54 kg) 16″ ahead of rear

idler shaft

3/8 - 1/2″ (1 - 1.3 cm)

If the track needs adjustment:

5. Loosen rear idler shaft bolt (D).

6. Loosen locknuts (A).

7. Tighten or loosen the track

adjusting screws (B) as

necessary to provide equal

adjustment on both sides of

the track.

Moving parts can cut and crush body parts. When performing the

checks and adjustments recommended on the following pages,

stay clear of all moving parts. Never perform track measurement

or adjustments with the engine running.

WARNING

C

B

A D

Track

Hi-fax

weight