1-3

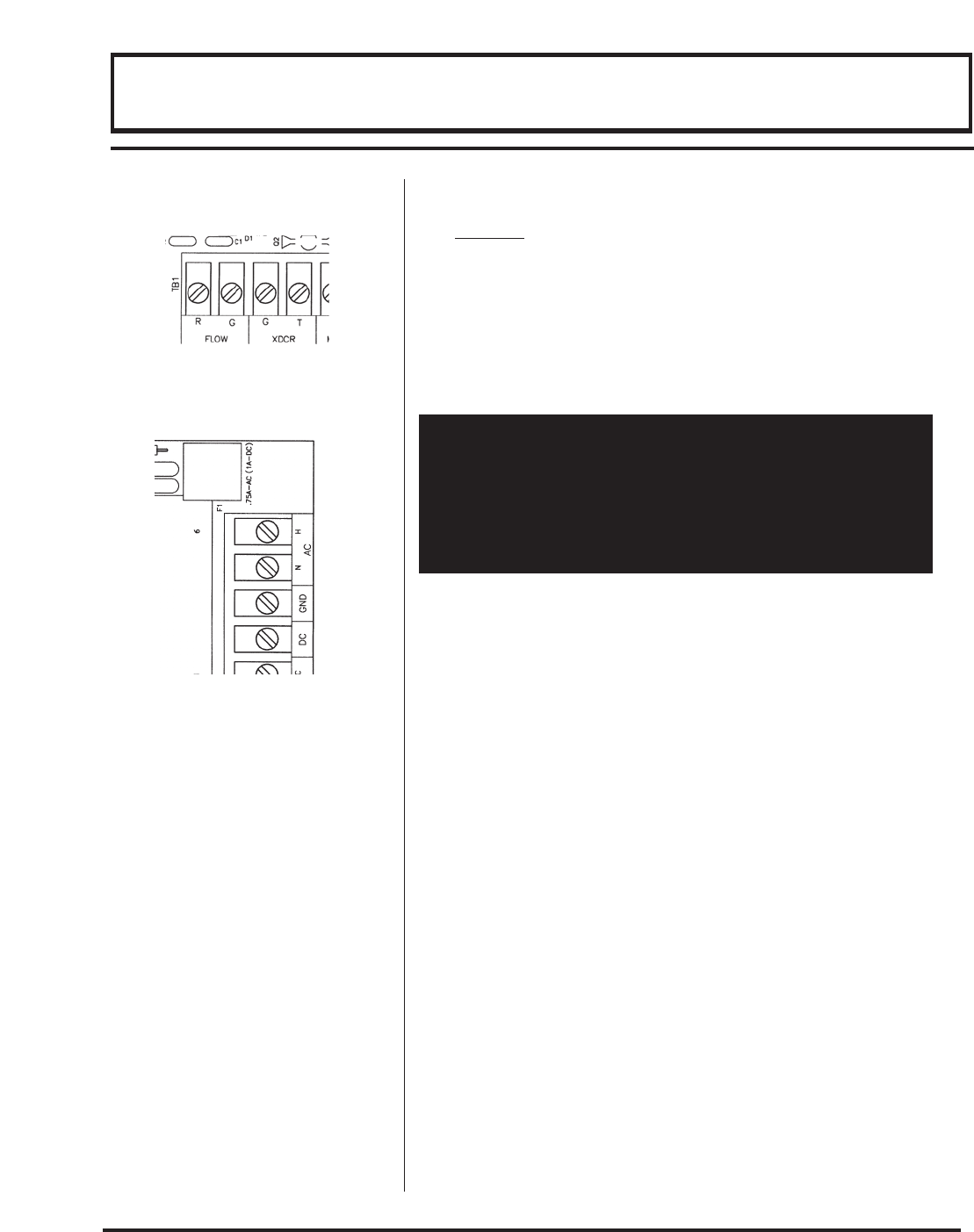

3. TRANSDUCER/POWER CONNECTIONS

A. Do not

attempt to add additional cable to the

transducers.

B. Refer to the DIAGRAMS in Figure 1.2 for proper power

and transducer connections. Verify proper jumper

selections are in place for the power source. See

Figure 3.4.

4. INITIAL SETTINGS AND POWER UP

A. Adjust the GAIN control [R13] to 1/4 turn from full

counter-clockwise rotation.

B. Apply power to the instrument.

C. If the pipe is full of a flowing liquid, the flow meter

signal strength will increase from a zero reading.(press

the

2nd FUNCT

key, then press

SIGNAL STR)

. If the

Signal Strength does not increase to a minimum of

000125 counts, gradually turn the GAIN control [R13]

clockwise until the indication is between 000125 and

000200. (Do not over adjust this setting as ambient

noise can influence readings.)

D. If possible, turn off the flow in the pipe. Verify that

SIGNAL STR. is lower than 000100. If SIGNAL STR.

is greater than 000100, verify that the sensor/

transmitter are not located near electrically noisy

components. (VFDs, inverters, motors, power relays,

etc) Verify that transducer connections are proper

and secure. If the SIGNAL STR. remains greater than

000100, consult the Dynasonics Factory for

assistance. It is possible that the GAIN control [R13] is

set too far clockwise and ambient noise is influencing

the readings. Turn the control counter-clockwise until

the signal strength decreases to below 000070 counts.

E. If the instrument passes steps 4C and 4D, the basic

setup of the instrument is complete.

PART 1 - QUICK START

IMPORTANT!

In order to successfully complete the configuration of

the FD6000 Series flow meter, the transducer must be

mounted on a pipe which is full of a flowing liquid. It

is normal to have a zero reading and no signal

strength indication with empty pipes or zero flow rate.

Figure 1.2

Transducer (top picture)

and Power (bottom picture)

Connections