DSGPULW DUOSCREED — OPERATION AND PARTS MANUAL — REV. # 6 (12/10/10) — PAGE 19

DSGPULW DUOSCREED — APPLICATION/OPERATION

Application/Operation

1. Before placing the DuoScreed in concrete for screeding,

it is a good idea to apply

form oil

to the blade and all

frame parts that may come in contact with the concrete.

This form oil will become useful when cleaning the

DuoScreed. Make sure to

saturate the unit with a good

amount of form oil.

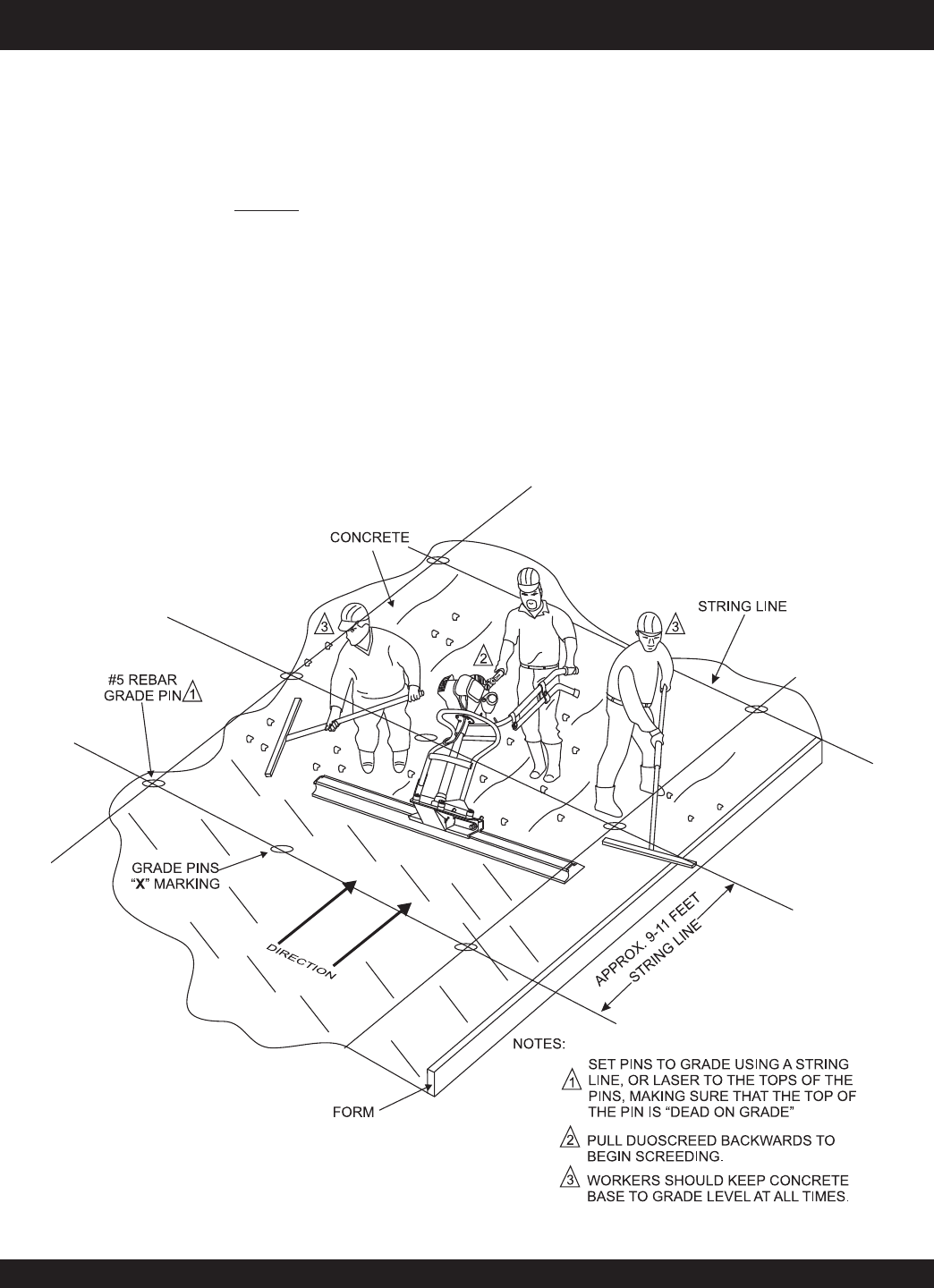

2. Prepare a grid of #5 rebar pins (Figure 14) equally spaced

approximately every 9 to 11 feet. If a 10 ft. screed blade

is going to be used space the grade pins every 9 feet, if

a 12 ft. screed blade is required, space the grade pins

every 11 ft. Make sure to drive the pins deeply into the

ground.

3. Use a

string line

or

laser

to set the pins to grade (height).

The grade should be to the top of the grade pins. Remem-

ber, before any concrete is to be poured, make sure that

the top of the pins are dead on grade.

Figure 14. DuoScreed On Forms and Grade Pins

4. Once all the grade pins have been placed correctly and

are dead on grade, concrete can then be poured on top

of grade pins.

5. Level, and form the concrete as close as possible to

grade. Mark the top of each pin so that its exact location

will be known. Use a hand trowel to float the edges and

plumbing grade pins.

6. If chalk lines are used for grade against forms, walls or

existing concrete, float out the grade with a hand float

along the edge.

7. Two workers will be required to assist the DuoScreed

operator when making the 12-18 concrete bases, one on

each side. These workers will rake the concrete in toward

the center of the DuoScreed away form the bases to avoid

changing base elevation.