DSGPULW DUOSCREED — OPERATION AND PARTS MANUAL — REV. # 6 (12/10/10) — PAGE 13

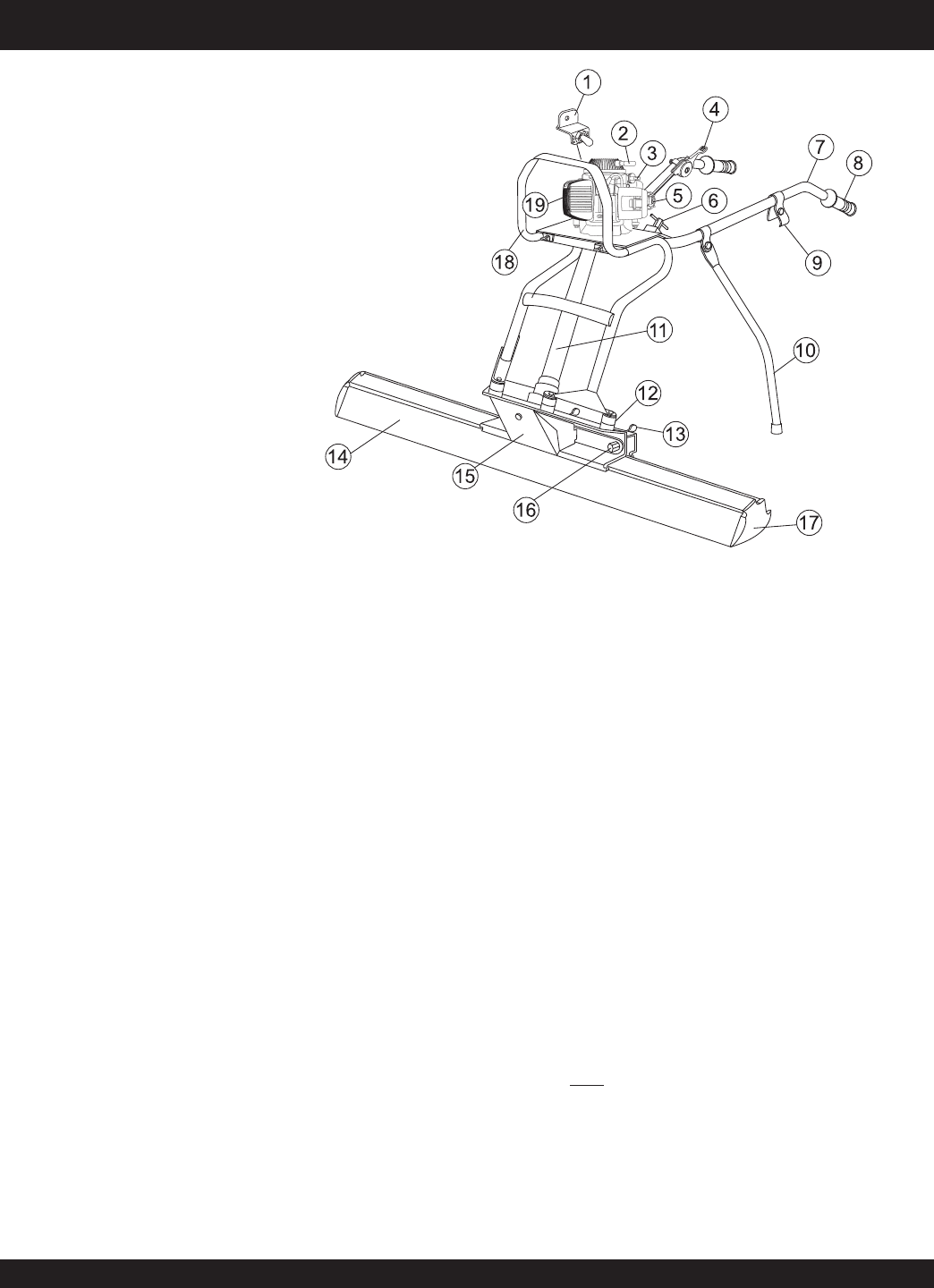

DSGPULW DUOSCREED — COMPONENTS

Figure 2. DuoScreed Components

Figure 1 shows the location of the components of the DuoScreed.

The function of each component is described below:

1. START/STOP Switch – When starting the engine, place

this switch in the START position. When stopping the

engine, place in the STOP position.

2. Recoil Starter – Manual-starting method. Pull the starter

grip until resistance is felt, then pull briskly and smoothly.

3. Oil Cap – Remove this cap to add engine oil.

4. Throttle Control Lever – Move the throttle lever to the

down

position for full throttle (max RPM's), for engine idle,

move the throttle lever to the

up

position.

5. Fuel Cap/ Tank – Remove the fuel tank cap to add unleaded

fuel ONLY! DO NOT mix fuel. DO NOT over fill. Tank

holds approximately .172 gallons (.65 liters).

6. Handle Bar Adjustment Knobs – Loosen these two

knobs to adjust the handle bar to a suitable working position.

7. Handle Bar – Used in the steering of DuoScreed.

8. Hand Grip – When operating the DuoScreed use this hand

grip to maneuver the machine.

9. Support Stand Latch – Use this latch to lock support

stand in place when DuoScreed is in operation.

10. Support Stand – Use this stand to support the DuoScreed

when not in use.

11. Flexible Drive Shaft– Connected to the drive shaft of the

engine, provides the vibrational force for the eccentric

weights.

12. Shock Mounts – Used to absorb the vibration generated

by the DuoScreed. These shock mounts minimize the

transfer of vibration to the operator.

13. Spring-Loaded Wing Nuts– Turn these 3 spring loaded

wing nuts counterclockwise to release the blade from the

aluminum clamping strip, turn clockwise to secure the blade

to the clamping strip.

14. Blades – The DuoScreed can be equipped with 2 different

type blade styles HD and LW. See Table 1 for details.

15. Eccentric Cover – Encloses the adjustable eccentric

weights. Press the spring clip tab inward and slide the cover

upward to gain access to the eccentric weights.

16. Locking Nuts – These 3 locking nuts are used in

conjunction with the 3 spring loaded wing nuts which

secure the blade to the aluminum clamping strip. Important!

always cover the two outer nuts with the provided plastic

cap. This will prevent concrete and other debris from

entering the quick disconnect system.

17. End Caps – Allows the DuoScreed to be maneuvered

around pipe or obstructions. End caps are used with HD

blades

only.

18. Lifting Bar– This bar is only for manual lifting on the jobsite.

Not to be used for manual lifting with a forklift or other lifting

device.

19. Gasoline Engine – This DuoScreed uses a HONDA

GX35SAT 1.6 HP gasoline engine. Refer to the

HONDA

owners manual for engine information and related topics.