PAGE 44 — MAYCO C-30HDNI (PRECISION) PUMP — OPERATION AND PARTS MANUAL — REV. #7 (04/03/12)

C-30HDNI (PRECISION) PUMP — MAINTENANCE (PUMP)

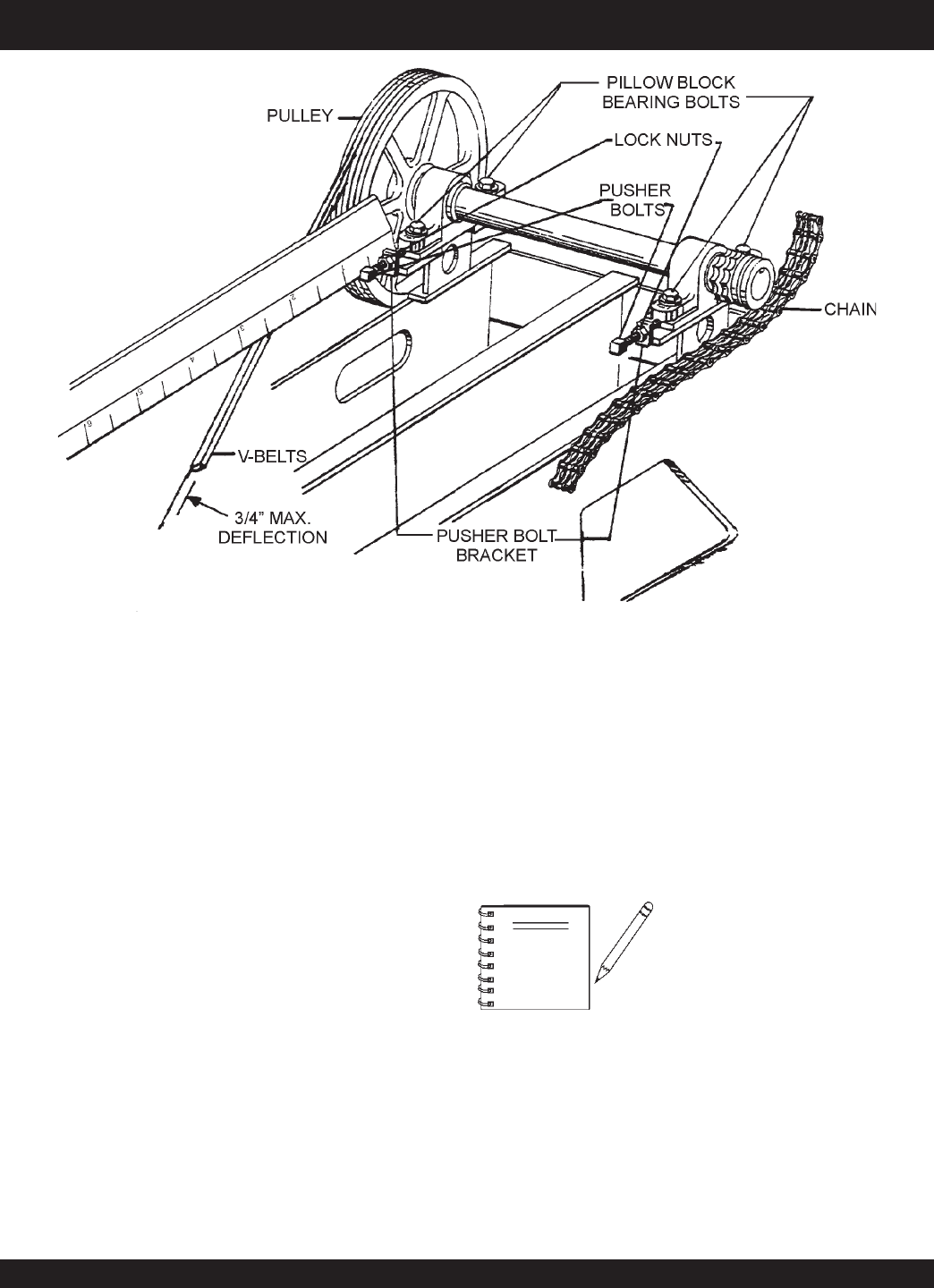

V-Belt And Drive Chain Adjustment

1. Loosen the pillow bearing bolts (Figure 27) only to the point

where the bolts will remain snug.

2 Unlock the two pusher bolt lock nuts.

3. Turn each pusher bolt clockwise an equal amount until the

chain is to proper adjustment of approximately 3/8 to 1/2 in.

slack in the chain. It is very important that the pulley side and

the chain side (pillow block bearings) are within 1/16” of an

equal distance.

4. This distance can be checked by using a tape measure or a

straight edge ruler, measuring from the inside of the pusher

bolt bracket to the face of the pillow block bearing.

5. The drive chain should be adjusted regularly to remove all

slack. Once all slack is removed, DO NOT over-adjust, as this

will overload the shaft bearings. A slack chain on the crank

drive creates backlash and shock loads on the shafts and

bearings which results in shorter wear/life of the drive com-

ponents.

6. Lubricate the chain regularly. Note-it is advisable to carry a

spare chain and master links for replacement in the field if

necessary.

Figure 27. V-Belt and Drive Chain Adjustment

Prior to adjusting the chain, place the

lobe of the cam in the down position.

The chain should have 83 rivets,

Including one each, half-link and full

link.

NOTE

7. Drive belts should be regularly adjusted to prevent slippage.

To adjust the belts, loosen the engine mounting bolts and

move the engine until there is a maximum 3/4 in. deflection

in the belts, retighten the engine mounting bolts.

8. Frequent inspections should be made on all drive compo-

nents to make certain that all bolts and nuts remain tight.