10 11

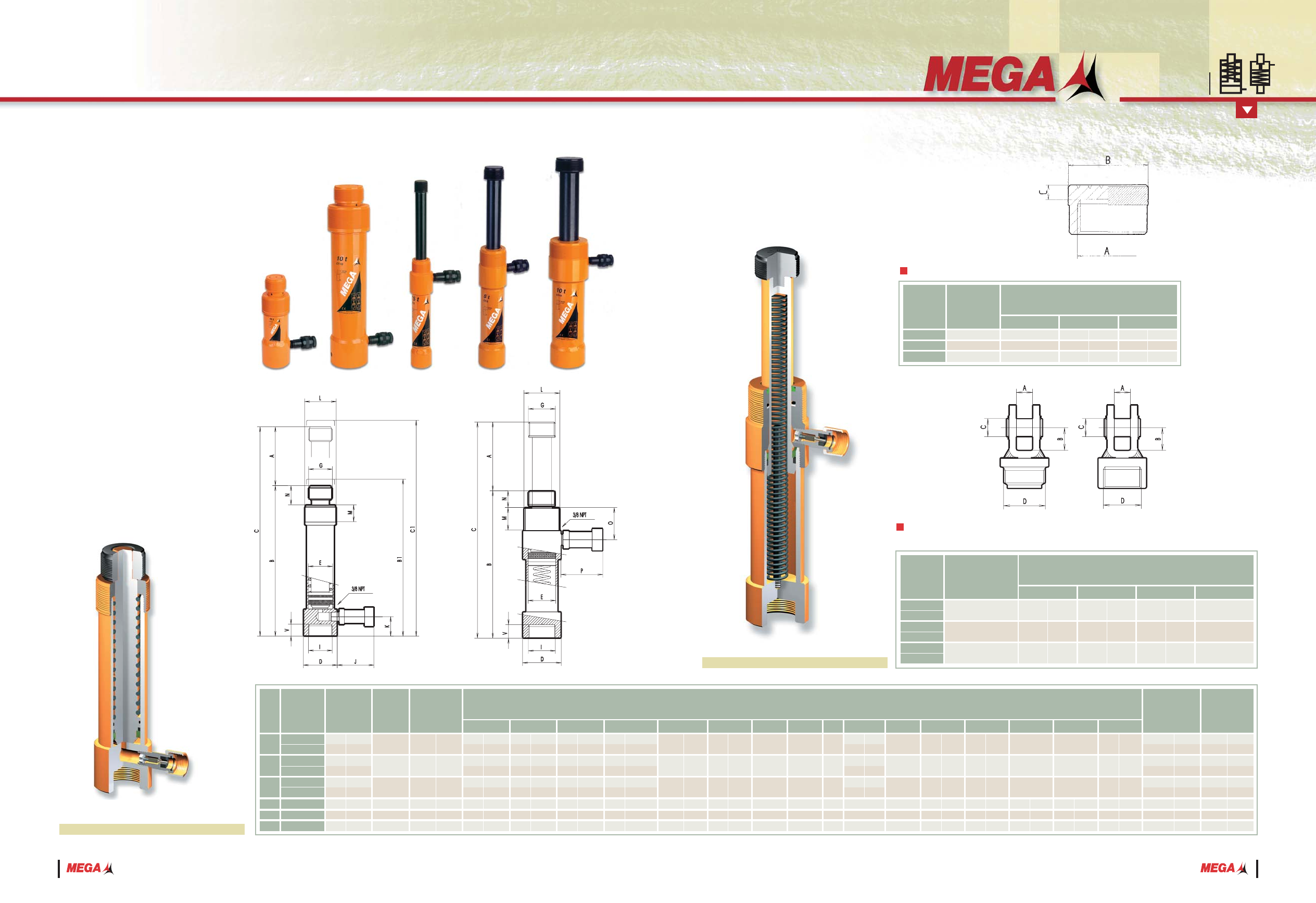

Coupling applications

CC

CT Series

HYDRAULIC CYLINDERS

CC: PUSHING

CT: PULLING

Working pressure: 700 kg/cm

2

/10.000 psi.

All pistons have an induction hardening

treatment or a salt bath nitriding process

depending on the model.

Each ram is equipped with a female quick

coupler with air dust cap, ref. A-5507-H.

With mounting holes and protected

threaded areas against possible blows for

easy coupling or special tooling applications.

Unlike the pushing cylinders, the pulling

rams retract toward the base to apply

pressure.

These pushing and pulling cylinders can

be original components of the Maintenance

Kits described on page 35.

Cross section view ( CC )

CC-5 SERIES

CC-10 SERIES

CC-20 SERIES

A-5142

A-5042

A-5242

Ref. Used with

ABC

Dimensions mm/in.

1

17

/64

2

7

/8

2

29

/32

8

10

12

5

/16

25

/64

15

/32

M26 x 2

M42 x 2,5

M60 x 2,5

32

54

74

Grooved saddle ( optional )

CC-5A

CC-5B

CC-10A

CC-10B

CC-20A

CC-20B

CT-2,5

CT-5

CT-10

5

10

20

2,5

5

10

Rated

capacity

Ref.

Maximum

capacity

Effective area

tn kN cm

2

in

2

BB1 CC1 DEGI

J

KNOPV

cm

3

in

3

Kg.

Oil volume WeightDimensions mm/in.

LM

lbs.

40

92

73

196

141

368

54

103

199

2,44

5,61

4,45

11,96

8,6

22,46

3,29

6,28

12,14

3

4,9

5,3

9,6

12,1

2,2

5

8,6

17,6

M26 x 2

M42 x 2,5

M60 x 2,5

M26 x 2

M42 x 2,5

M60 x 2,5

70

2

3

/4

70

2

3

/4

70

2

3

/4

----

----

----

1,35

2,2

2,4

4,35

5,5

10

2,25

3,9

8

50

115

50

135

50

130

127

138

138

2

4

1

/2

2

5

5

/16

2

5

1

/8

5

5

7

/16

5

7

/16

55

99,6

194

29,1

51,1

99

8,04

14,52

28,27

4,24

7,45

14,41

1,24

2,25

4,38

0,65

1,15

2,23

177

284

191

332

216

364

270

311

318

6

15

/16

11

3

/16

7

1

/2

13

1

/16

8

1

/2

14

5

/16

10

5

/8

12

1

/4

12

1

/2

184

292

201

342

228

376

----

----

----

7

5

/16

11

1

/2

7

15

/16

13

7

/16

9

14

13

/16

----

----

----

227

399

241

467

266

494

397

449

456

8

15

/16

15

11

/16

9

1

/2

18

3

/8

10

1

/2

19

7

/16

15

5

/8

17

11

/16

17

15

/16

235

407

251

477

278

506

---

---

---

9

1

/4

16

9

7

/8

18

3

/4

10

15

/16

19

15

/16

---

---

---

Stroke

A

mm. in.

M26 x 2

M42 x 2,5

M60 x 2,5

M26 x 2

M42 x 2,5

M60 x 2,5

45

60

79

45

60

79

M38 x 1,5

M56 x 2

M84 x 2

M38 x 1,5

M56 x 2

M84 x 2

----

----

----

70

70

70

2

3

/4

2

3

/4

2

3

/4

----

----

----

70

70

70

2

3

/4

2

3

/4

2

3

/4

----

----

----

33

30

38

35

44

40

1

5

/

16

1

3

/

16

1

1

/

2

1

3

/

8

1

3

/

4

1

9

/

16

B1, C1 with tilting saddle

1

49

/64

2

11

/32

3

1

/8

1

49

/64

2

11

/32

3

1

/8

32

43

60

32

43

60

1

1

/4

1

11

/16

2

11

/32

1

1

/4

1

11

/16

2

3

/8

22

36

48

24

35

35

7

/8

1

7

/16

1

7

/8

15

/16

1

3

/8

1

3

/8

20

26

30

21

24

27

13

/16

1

1

/32

1

3

/16

1

13

/16

15

/16

1

1

/16

18

21

23

16

21

21

11

/16

13

/16

7

/8

5

/8

13

/16

13

/16

Cross section view ( CT )

CC-5, CT-2,5 SERIES

CC-10, CT-5 SERIES

CC-20, CT-10 SERIES

A-5188

A-5189

A-5088

A-5089

A-5288

A-5289

Ref. Used with

ABC

Dimensions mm/in.

1

1

1

3

/16

20

20

20

25

/32

25

/32

25

/32

18

18

18

23

/32

23

/32

23

/32

25

25

30

D

M26 x 2

M42 x 2,5

M60 x 2,5

Attachments for pulling and

pushing pistons ( optional )

Single-acting, spring return