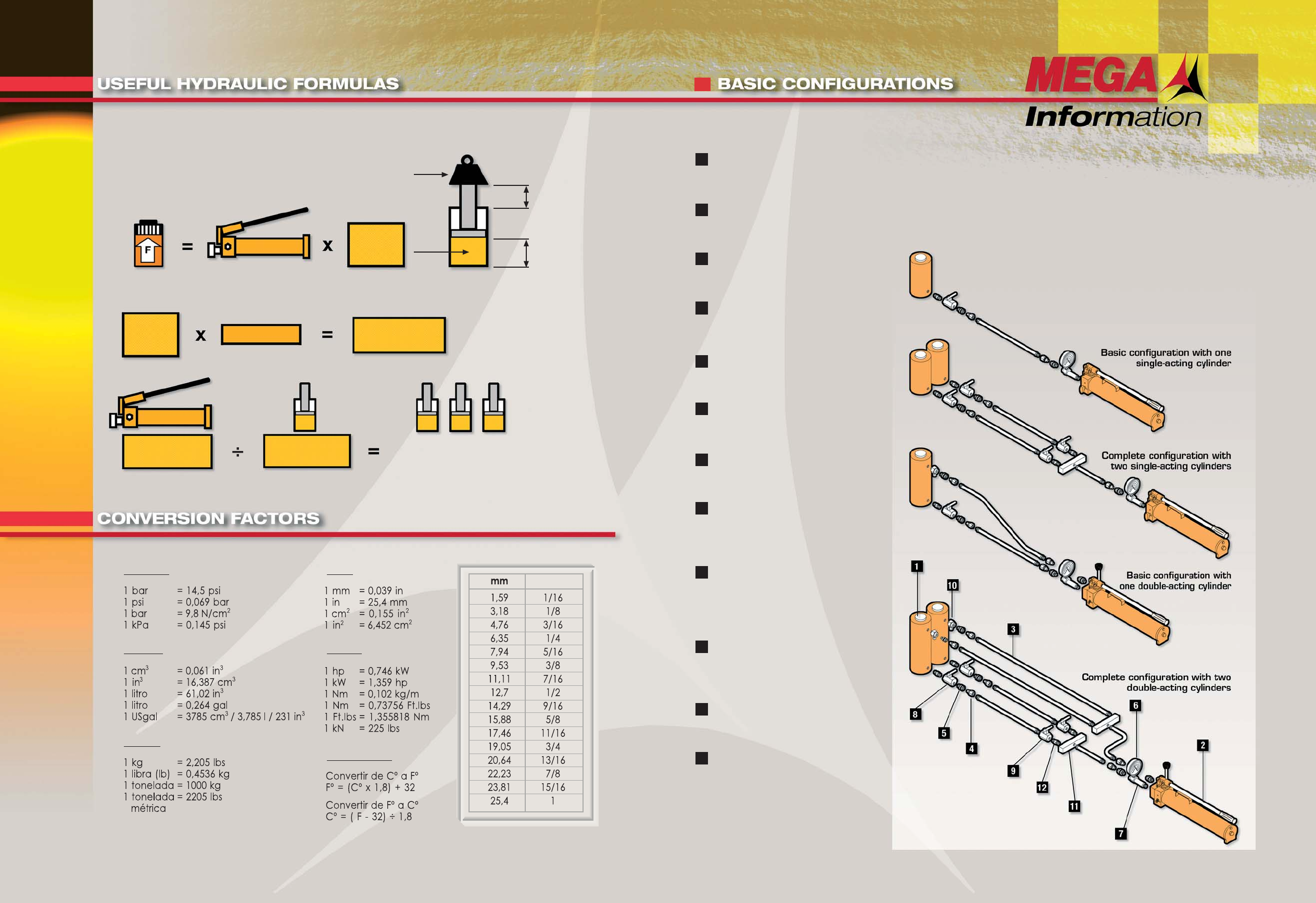

A basic hydraulic configuration consists of a single-acting cylinder, a pump

and a hose. It is really a small machine with the following components:

a) Flow generator = Pump. b) Flexible hose to transmit the oil flow from pump

to cylinder. c) Hydraulic cylinder, consisting of a chamber with inlet for the

oil and a piston to retain the oil and maintain the pressure that raises or

lowers as the oil changes within the chamber. The pressure is

created by resistance to flow. This resistance is the result

of a load. This hydraulic equipment can be used in

virtually all types of industry. From a basic pump

and cylinder set, you can build many

different system configurations by

adding components and

accessories.

1

2

3

4

5

6

7

8

9

10

11

12

Cylinder

To raise the load.

Page 8

Pump

Creates the hydraulic flow.

Page 24

Hose

Transmits the oil flow.

Page 28

A-5507-M

Male quick coupler

Page 28

A-5507-H

Female quick coupler

Page 28

Gauge

To control pressure.

Page 29

Gauge adapter

To mount the gauge.

Page 29

A-5510

Safety valve

Locks the load on raised cylinder.

Page 30

A-5509

Shutoff valve

Shuts the oil flow and locks

the load on raised cylinder.

Page 30

A-5538

Safety relief valve

Avoids accidental overpressure.

Page 30

Manifold

To distribute the oil flow.

Page 31

12 A-5511

Male connector

To connect different components.

Page 31

Capacity (kg)

Pressure (kg/cm

2

- psi)

Effective

area

(cm

2

/ in

2

)

Stroke

Volume of oil

(cm

3

/ in

3

)

Load

Cylinder

effective area

Stroke

Oil volume

of cylinder

Oil volume

of pump

Oil volume

of cylinder

Number of cylinders that can be used with

one pump.

With long hoses, add 35 cm

3

for each meter

used.

Basic hydraulic calculations for the correct selection of cylinders and pumps.

cm

3

/ in

3

cm / in

cm

2

in

2

Pressure:

Volume:

Weight:

Area:

Others:

Temperature:

Inches

Please note that the dimensions of this catalogue are exact in the metric system ( mm )

and approximate in inches.