20 21

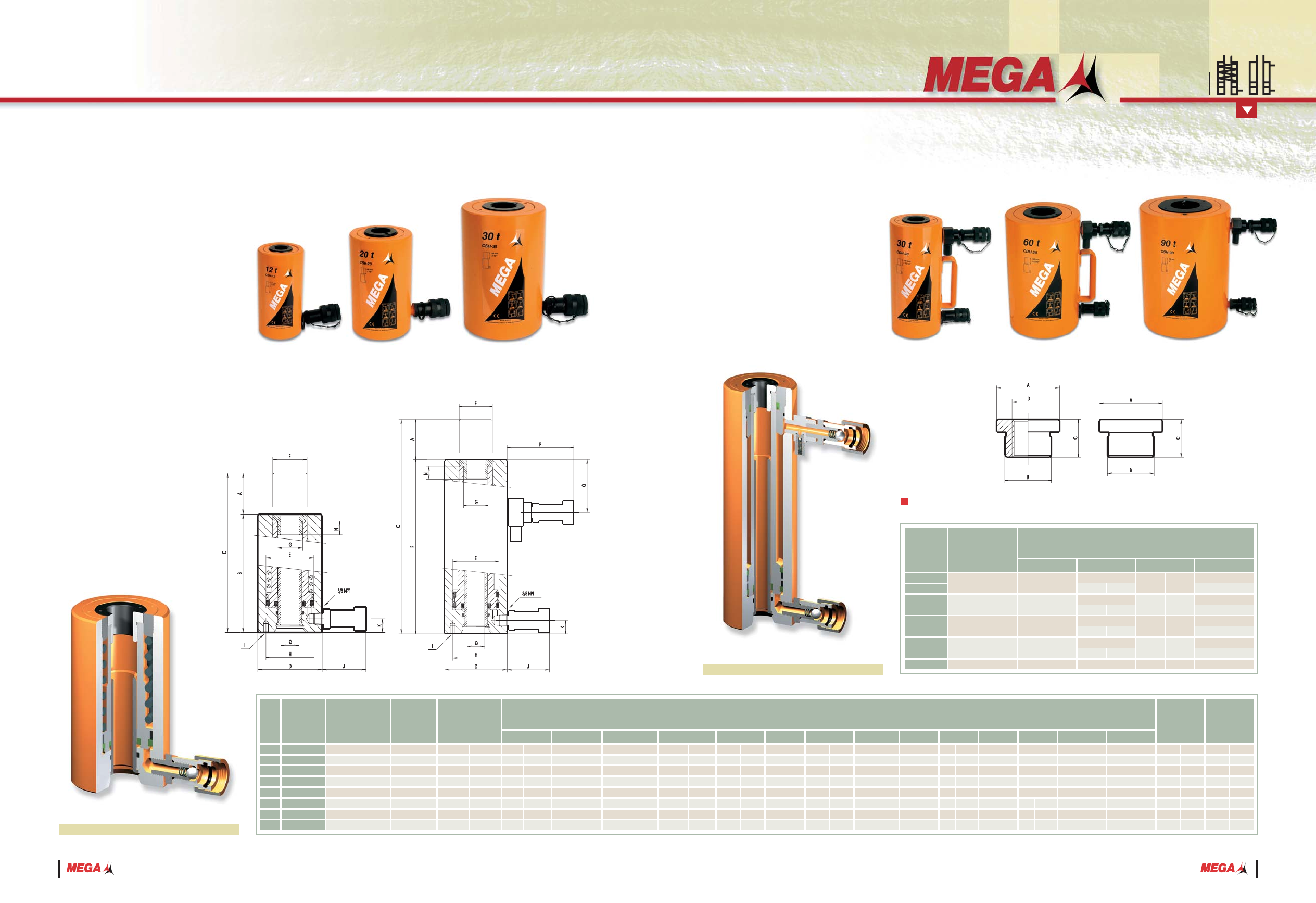

CSH: Single-acting, spring return

CDH: Double-acting, hydraulic return

CSH

CDH Series

HYDRAULIC CYLINDERS

CSH: SINGLE-ACTING

CDH: DOUBLE-ACTING

Working pressure: 700 kg/cm

2

/10.000 psi.

All pistons have a salt bath nitriding treatment

to resist corrosion.

With built-in bronze guide for easier sliding

of piston.

These cylinders are fitted with a removable

saddle, and are also equipped with a high

flow female quick coupler with dust cap, ref.

A-5507-H.

Carry handles on models weighing from

20 kg/44 lbs to 40 kg/88 lbs. Heavier models

are fitted with eye hooks for transport.

With mounting holes and threaded areas for

easy coupling or special tooling applications.

Fitted with a relief safety valve, ref. A-5538,on

the piston retract side, to prevent accidental

overpressure.

Hollow piston cylinders

The hollow cylinders can be used for general

applications of pushing or lifting forces.

Additionally, they feature a centre-hole

piston which allows the insertion of a rod

or screw, attachable to the threaded saddle,

that travels through the cylinder for pulling

or pushing operations.

Ideal for tensioning, extracting, gear and

pin removal etc.

CSH-12

CSH-20

CSH-30

CSH-60

CSH-90

CDH-30

CDH-60

CDH-90

12

20

30

60

90

30

60

90

Nominal

capacity

Ref.

Maximum

capacity

Effective area

tn kN cm

2

in

2

BCD PQ

cm

3

in

3

Kg.

Oil volume WeightDimensions mm/in.

lbs.

74

140

270

640

1010

638

1265

1995

4,5

8,5

16,5

39

61,6

39

77,2

121,8

8,3

17,6

28,6

58,5

143

42,2

72

163

3,8

8

13

26,6

65

19,2

32,7

74

1

5

/8

1

7

/8

2

1

/2

3

3

5

15

/16

5

15

/16

5

15

/16

18,03

28,86

42,51

84,34

133

42,51

84,34

133

2,8

4,5

6,6

13

20,6

6,6

13

20,6

5

11

/16

6

3

/4

7

7

/8

9

5

/8

10

11

/16

11

11

/16

11

7

/8

12

3

/16

7

5

/16

8

11

/16

10

3

/8

12

5

/8

13

11

/16

17

9

/16

17

13

/16

18

1

/64

70

95

110

155

200

110

155

200

2

3

/4

3

3

/4

4

5

/16

6

1

/8

7

7

/8

4

5

/16

6

1

/8

7

7

/8

Stroke

A

mm. in.

4

7

/16

4

7

/16

4

7

/16

49

/64

1

3

/64

1

19

/64

2

1

/64

3

1

/64

1

19

/64

2

1

/64

3

1

/64

119,3

196,6

291,7

578,8

867

291,7

578,8

880

113

113

113

19,5

26,5

33

53,5

79

33

53,5

79

145

172

200

245

272

296

302

310

186

220

263

321

348

446

452

460

EFGHI

J

KN

2

11

/64

2

3

/4

3

3

/8

4

15

/16

6

1

/2

3

3

/8

4

15

/16

6

1

/2

1

23

/64

2

2

7

/16

3

45

/64

5

3

/64

2

7

/16

3

45

/64

5

3

/64

2

3

1

/4

3

5

/8

5

1

/8

----

3

5

/8

5

1

/8

----

5

/16 - 18 UNC

3

/8 - 16 UNC

3

/8 - 16 UNC

1

/2 - 13 UNC

----

3

/8 - 16 UNC

1

/2 - 13 UNC

----

2

3

/4

2

3

/4

2

3

/4

2

3

/4

2

3

/4

2

3

/4

2

3

/4

2

3

/4

25

/32

25

/32

25

/32

25

/32

1

1

/2

25

/32

25

/32

1

1

/2

25

/32

25

/32

7

/8

1

1

3

/16

7

/8

1

1

3

/16

38,5

50,5

62

94

128

62

94

128

M29 x 1,5

M37 x 1,5

M46 x 1,5

M72 x 1,5

M104 x 1,5

M46 x 1,5

M72 x 1,5

M104 x 1,5

50,8

82,6

92,1

130,2

----

92,1

130,2

----

70

70

70

70

70

70

70

70

20

20

22

25

30

22

25

30

20

20

20

20

38

20

20

38

41

48

63

76

76

150

150

150

55

70

85,72

125

165,1

85,72

125

165,1

O

1

27

/32

1

7

/8

2

47

48

50

----

----

----

----

----

----

----

----

----

----

Cross section view ( CSH)

CSH-12

CSH-20

CSH-30, CDH-30

CSH-60, CDH-60

CSH-90, CDH-90

BRCSH-12

BMCSH-12

BRCSH-20

BMCSH-20

BRCSH-30

BMCSH-30

BRCSH-60

BMCSH-60

BMCSH-90

Ref. Used with

ABC

Dimensions mm/in.

1

6

/64

1

25

/64

1

3

/4

2

49

/64

27,2

35,2

44,2

70,2

M29 x 15

M37 x 1,5

M46 x 1,5

M72 x 1,5

M104 x 1,5

D

3

/4 - 16 UNF

----

1 - 8 UNC

----

1

1

/4 - 7 UNC

----

1

5

/8 - 5

1

/2 UNS

----

----

38

50

61

93

127

1

1

/2

2

2

13

/32

3

21

/32

5

28

30

32

37

42

1

1

/64

1

3

/16

1

1

/4

1

29

/64

1

21

/32

Threaded saddle ( optional )

Grooved saddle ( optional )

Cross section view ( CDH )