16 17

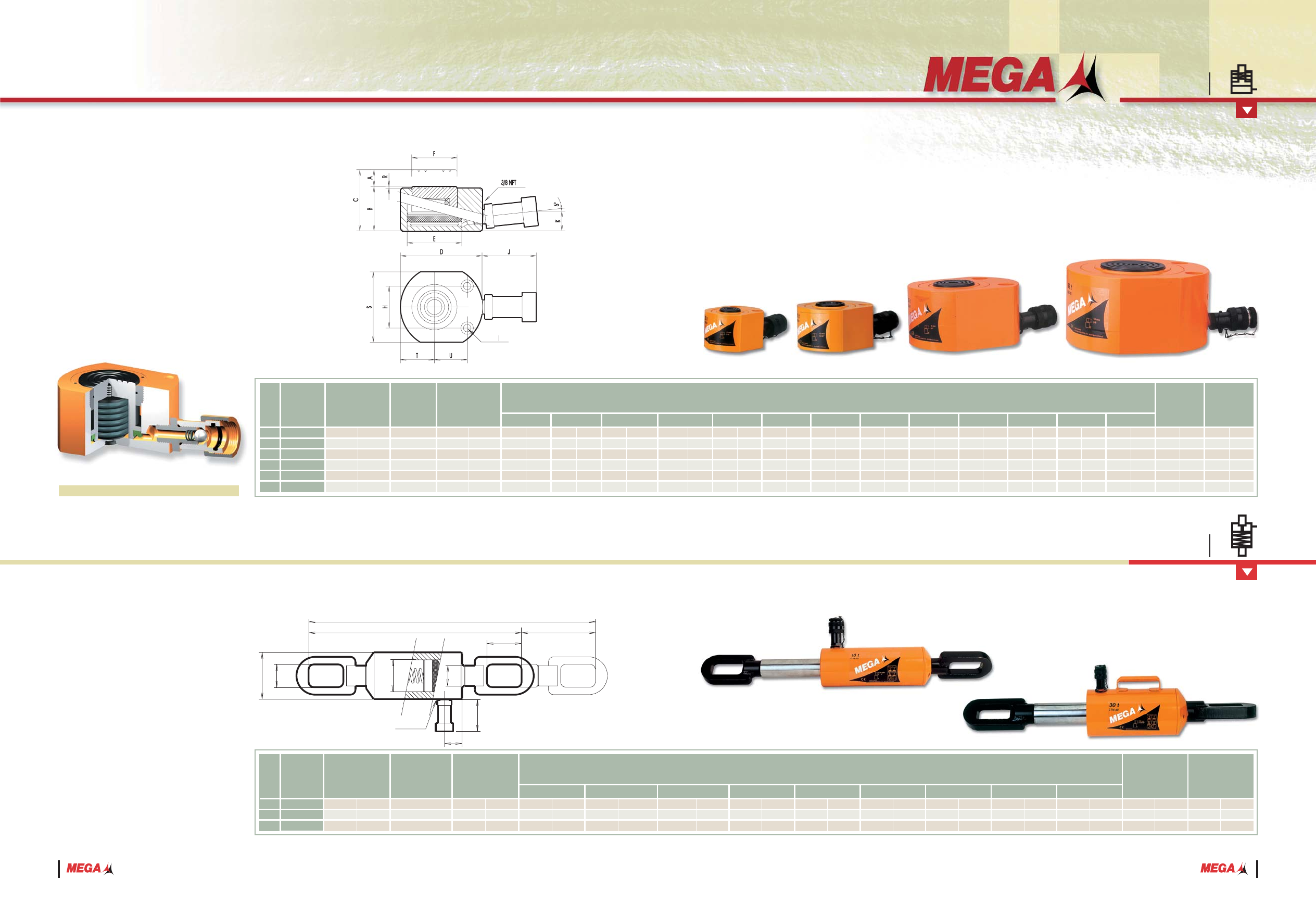

Flat cylinders

CSE Series

HYDRAULIC CYLINDERS

Working pressure: 700 kg/cm

2

/10.000 psi.

All pistons have a salt bath nitriding treatment

to resist corrosion.

Grooved piston ends make optional grooved

saddle unnecessary.

All are equipped with high flow female quick

couplers with dust cap, ref A-5507-H, except

model CSE-5 fitted with a female quick coupler,

ref. A-5506-H.

With mounting holes in the base.

These CSE cylinders have been designed

to combine minimum collapsed height with

optimum stroke.

They are suitable for lifting, clamping,

levelling or positioning jobs where space is

tight.

The spring return piston allows easy removal

from working place.

Working pressure: 700 kg/cm

2

/10.000 psi.

All pistons have a hard chrome plating

treatment to resist corrosion.

Equipped with high flow female quick coupler

with dust cap, ref. A-5507-H and carrying handle.

Designed for pulling and tensioning

applications, they can be used in those

operations where two heavy pieces have to be

put one near the other.

They are normally used in industrial assembling,

testing, welding operations of plates or heavy

steel frame works.

They are fitted with clevis eyes on both ends

which are linked to attachments welded onto

the plates to join or weld.

AB

C

X

D W

P

O

3/8 PNT

E

F

127

150

150

5

5

15

/16

5

15

/16

CTN-10

CTN-30

CTN-50

10

30

50

Nominal

capacity

Ref. Stroke

Maximum

capacity

Effective area

tn

A

kN cm

2

in

2

BC DEF0PW

X

cm

3

in

3

Kg.

Oil volume WeightDimensions mm/in.

lbs.

mm. in.

183

725

1085

11,15

44,3

66,2

21,1

48,6

81,4

625

775

920

24

9

/16

30

1

/2

36

7

/32

60

100

125

2

11

/32

3

15

/16

4

15

/16

85

125

155

3

11

/32

4

15

/16

6

1

/8

18

11

/16

24

9

/16

30

5

/16

9,6

22,1

37

98,95

331,8

497,2

14,42

48,34

72,45

2,23

7,49

11,23

475

625

770

42

62

80

1

21

/32

2

7

/16

3

6

/32

35

40

44

1

3

/8

1

9

/16

1

3

/4

70

70

70

2

3

/4

2

3

/4

2

3

/4

40

50

60

1

9

/16

2

2

11

/32

75

100

150

2

15

/16

3

15

/16

5

15

/16

CSE-5

CSE-11

CSE-23

CSE-31

CSE-55

CSE-93

5

11

23

31

55

93

Nominal

capacity

Ref.

Maximum

capacity

Effective area

tn kN cm

2

in

2

BCD TU

cm

3

in

3

Kg.

Oil volume WeightDimensioes mm/in.

lbs.

5

18

37

53

125

212

0,77

2,8

5,73

8,2

19,4

32,8

1,65

3,85

7,05

10,5

20,7

37,9

0,75

1,75

3,2

4,8

9,4

17,2

1

/4

7

/16

7

/16

15

/32

5

/8

5

/8

7,06

15,9

33,08

44,18

78,54

132,73

1,09

2,46

5,12

6,84

12,17

20,57

1

3

/8

1

3

/4

2

1

/8

2

11

/32

2

27

/32

3

15

/32

1

19

/32

2

3

/16

2

9

/16

2

27

/32

3

15

/32

4

3

/32

60

79

98

115

147

180

2

11

/32

3

1

/8

3

7

/8

4

17

/32

5

25

/32

7

3

/32

Stroke

A

mm. in.

13

/16

1

1

/64

1

9

/16

1

13

/16

2

7

/16

3

1

/8

7

/8

1

5

/16

1

7

/16

1

3

/4

2

5

/16

2

15

/16

48,5

109,1

227,7

303,1

539

910,9

20

28

40

47

62

80

22

34

37

44

58

75

6,5

11

11

12

16

16

34

44,5

54

60

72

88

40,5

55,5

65

72

88

104

EFHIJ

K

RS

30

45

65

75

100

130

1

3

/16

1

49

/64

2

9

/16

2

61

/64

3

15

/16

5

1

/64

1

1

/32

1

17

/32

2

1

/8

2

1

/4

3

6

/32

4

9

/64

1

3

/32

1

29

/64

2

2

3

/64

2

3

/4

3

7

/32

1

/4

23

/64

23

/64

7

/16

9

/16

2

11

/32

2

3

/4

2

3

/4

2

3

/4

2

3

/4

2

3

/4

11

/16

15

/16

15

/16

15

/16

15

/16

15

/16

3

/64

3

/64

3

/64

3

/64

3

/64

3

/64

1

5

/8

2

13

/64

3

1

/8

3

11

/16

4

7

/8

6

5

/16

26

39

54

57,15

80

105

28

37

50

52

70

76

5,5

6,6

9

9

11

14

60

70

70

70

70

70

17

23

23

23

23

23

41

56

80

94

124

160

1

1

1

1

1

1

Cross section view

CTN Series

Pulling cylinders

HYDRAULIC CYLINDERS

Single-acting, spring-return

Single-acting, spring return