7.5

Section 7

Cooling System

7

Hoses and Tubes

Hoses and tubes are used to connect the components

within the cooling system. To guard against coolant

loss and hose failure, the hoses, tubes and their

connections should be checked regularly for leaks or

damage. Loss of coolant can result in serious engine

damage. Over time, engine vibration can affect hose/

joint connections, and the hoses themselves can be

affected by heat and the coolant. Swelling, hardening,

and/or deterioration can occur depending on the

operating environment involved. Deterioration usually

takes place more rapidly from the inside, making

outside inspections incomplete and not always

dependable. Regular outside inspection and careful

inside inspection whenever connections are opened,

can minimize a possible ‘‘in-service’’ problem.

Use new clamps whenever replacing a hose or a joint

connection is opened, to assure proper retention and

avoid leakage as a result of insufficient tension.

When making hose connections, a light coating of

rubber lubricant will make assembly easier.

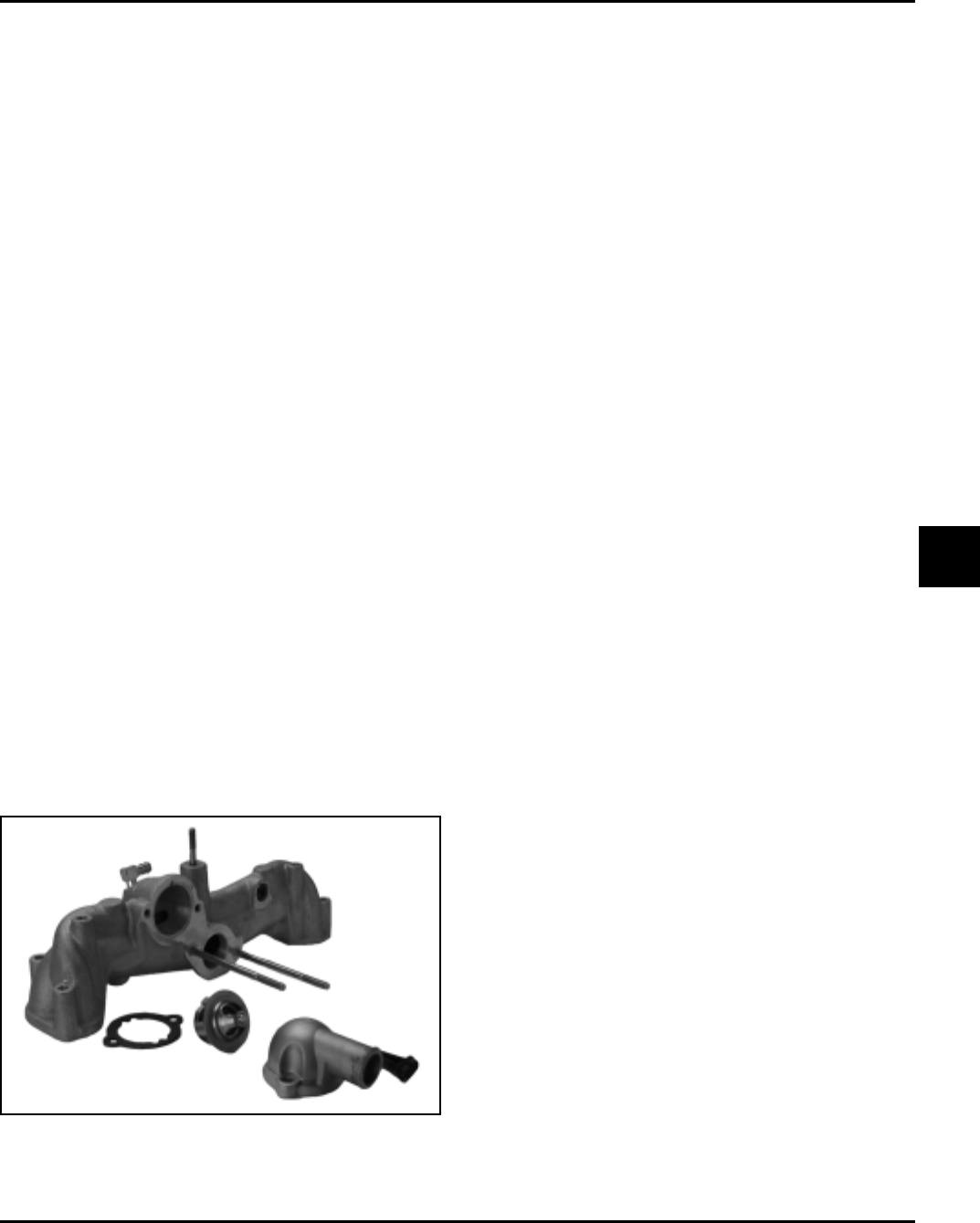

Thermostat Testing and Servicing

The thermostat is mounted in the intake manifold,

beneath the thermostat housing. See Figure 7-9. It

controls the rapid warm-up and operating temperature

of the engine. If a problem is encountered which is

thought to be the fault of the thermostat, it can be

checked to determine its operating condition. Before

removing and testing the thermostat, make sure all

other possible causes such as debris accumulation,

obstruction, leaks, coolant level, and damaged

components are eliminated as possible causes.

To Test

Remove the thermostat from the system. Hang or

suspend the thermostat by its frame in a container of

water, so the thermostat does not touch the bottom of

the container. Heat the water and measure the

temperature (an oven thermometer can be used). The

spring-loaded valve of the thermostat should begin to

open at 79.4º C (175º F), and can be completely open

at 90º C (195º F). If the valve opens at a temperature

more than 10 degrees below the specified opening or

fails to open at a temperature 10 to 15 degrees above

the specified opening, the thermostat should be

replaced. If the valve in the thermostat can be moved

or pushed off its seat with a slight effort when the

thermostat is cold, the unit may be considered

defective and should be replaced. The thermostat

should be replaced if operation is found to be

questionable or faulty.

Installation

1. Thoroughly clean the sealing surfaces of the

intake manifold and thermostat housing with an

aerosol gasket remover. Make sure the sealing

surfaces are clean and free of nicks or damage.

Make sure the notch in the intake manifold is

clean.

2. Install a new thermostat into the intake manifold,

so the larger spring end is down into the well of

the intake manifold. Position a new thermostat

gasket on the intake manifold.

3. Install the thermostat housing so the outlet faces

away from the mounting surfaces of the intake

manifold.

4. Install and torque the two hex. flange screws to

9.9 N·m (88 in. lb.).

5. Reconnect the radiator hose and secure with the

hose clamp, if separated previously.

Figure 7-9. Intake/Thermostat.