DISASSEMBLY, REASSEMBLY, INSPECTION, AND MAINTENANCE 3-39

Piston and Connecting Rod

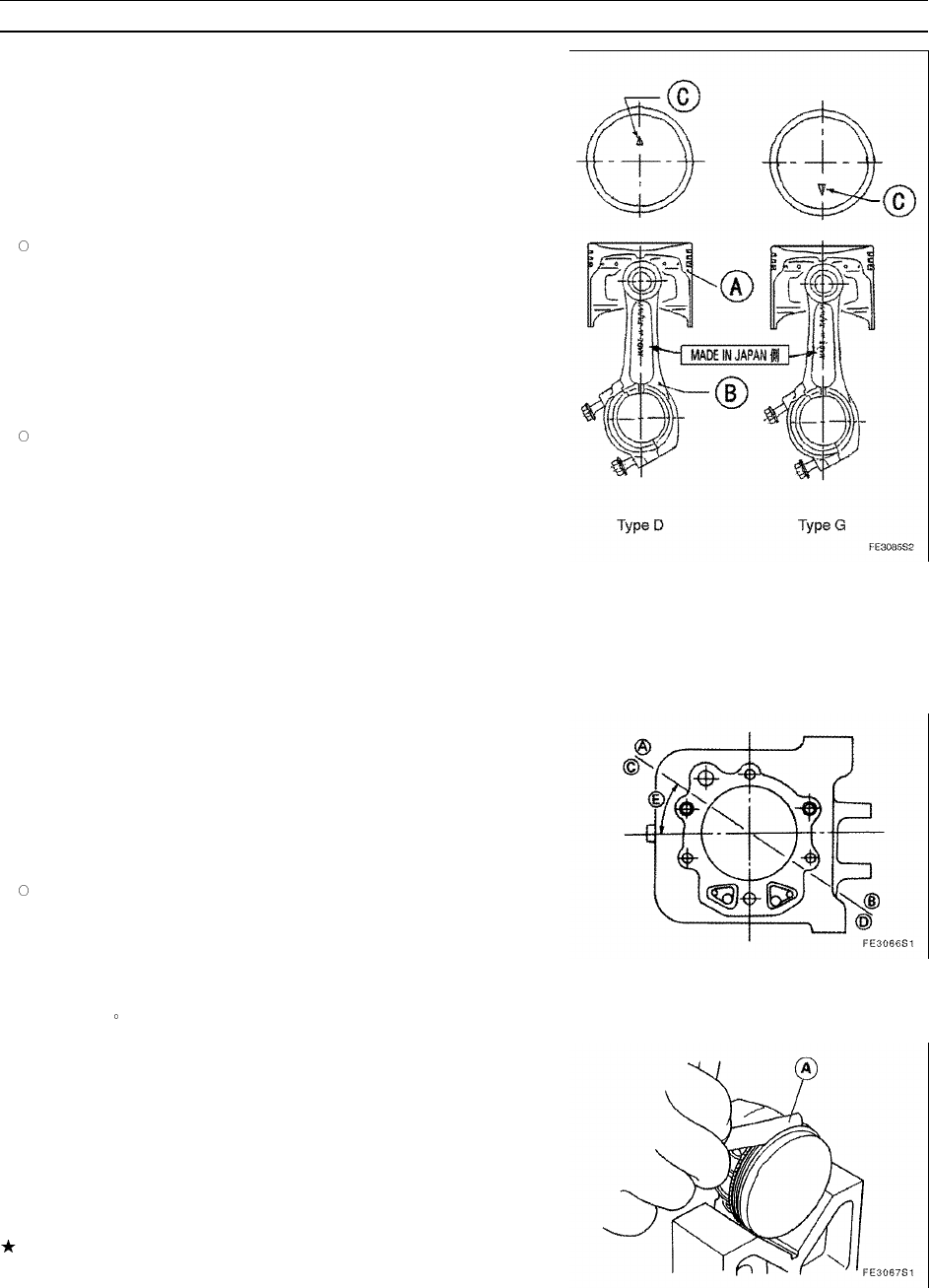

For FE290

•

On type D, face the arrow on the top of the piston opposite to the

side of the connecting rod marked "MADE IN JAPAN".

•

On type G, face the arrow on the top of the piston towards the side

of the connecting rod marked "MADE IN JAPAN".

•

Replace the snap ring for the piston pin with a new one and fit it

securely into the groove of the piston pin hole.

NOTE

Do not reuse an old snap ring. Once a snap ring is removed, it

could be deformed or it could have lost its tension. If it is reused, it

could fall out while the engine is running, and damage the cylinder

wall.

•

When installing the piston and connecting rod assembly into the

cylinder, beware of the direction of the "MADE IN JAPAN" side of

the connecting rod.

NOTE

Apply engine oil to the cylinder bore, crank pin area, connecting

rod big end, and connecting rod bolts before reassembly.

A: Piston

B: Connecting Rod

C: Arrow

For FE120, 170, 250, 350, 400

•

On both types D and G, the "MADE IN JAPAN" side of the connecting

rod must face the magneto.

For FE290

On both types D and G, the "MADE IN JAPAN" side of the connecting

rod must face the output shaft.

•

Arrange the gaps of the piston rings as shown in the diagram, and

use a ring compressor to install the piston from the cylinder head

side.

•

Mate the connecting rod cap to the big end of the connecting rod and

tighten the connecting rod bolts to the specified torque. (Refer to the

section on Tightening Torque Specifications.)

NOTE

After tightening the bolts, make sure that the connecting rod moves

easily in the axial direction along the crank pin.

A: Top Ring Gap Position

B: Second Ring Gap Position

C: Upper Side Rail Gap Position

D: Lower Side Rail Gap Position

E: 30 ~ 45

Piston Inspection

•

Clean the carbon deposits off the piston.

•

Using a new piston ring, use a gap gauge [A] to measure the

clearance between the ring groove and the ring.

Piston Ring Groove Clearance Service Limit (maximum)

Top Ring Second Ring

FE120, 170, 250: 0.15 mm (0.0059 in) 0.12 mm (0.0047 in)

FE290, 350, 400: 0.16 mm (0.0063 in) 0.14 mm (0.0055 in)

If the measured value is greater than the service limit, replace the

piston with a new one.