2 03524832_ed12

Product Safety Information

Intended Use:

The 150BMG Series Air starters are intended for use in starting reciprocating internal combustion engines. These starters are designed

to be operated from a remote location after proper installation on the engine requiring starting.

For Additional information refer to Air Starters Product Safety Information Manual Form 45558624.

Manuals can be downloaded from www.ingersollrandproducts.com

Lubrication

Ingersoll Rand strongly emphasizes the importance of proper

lubrication for achieving top performance and maximum durability

with this starter. Either one of two lubrication systems is

recommended.

For typical starter installations where the cranking cycle is less than

10 seconds, we recommend an Ingersoll Rand No. HDL3 Lubricator

installed as shown in Dwg. TPC585. Use either diesel fuel or 10W

nondetergent motor oil for lubricating the starter.

NOTICE

When an HDL3 Lubricator is used, make certain that the oil sup-

ply line pressure is no greater than 5 psi. If there is pressure on

the line, the lubricator will continuously leak lubricant through

the starter and out of the exhaust.

If the cranking cycle is more than 10 seconds, we recommend the

Ingersoll Rand No. Lubricator NL-24-8 installed in the main air

supply line. Use a good quality 10W nondetergent oil and adjust the

lubricator to ow 1 to 3 drops per second.

Placing the Starter in Service

How to Order a Starter

Size Starter

Type Starter

Gas Sealed

Gearing

Drive

Drive Housing

Inlet

Type Pinion

Exhaust

Drive Housing

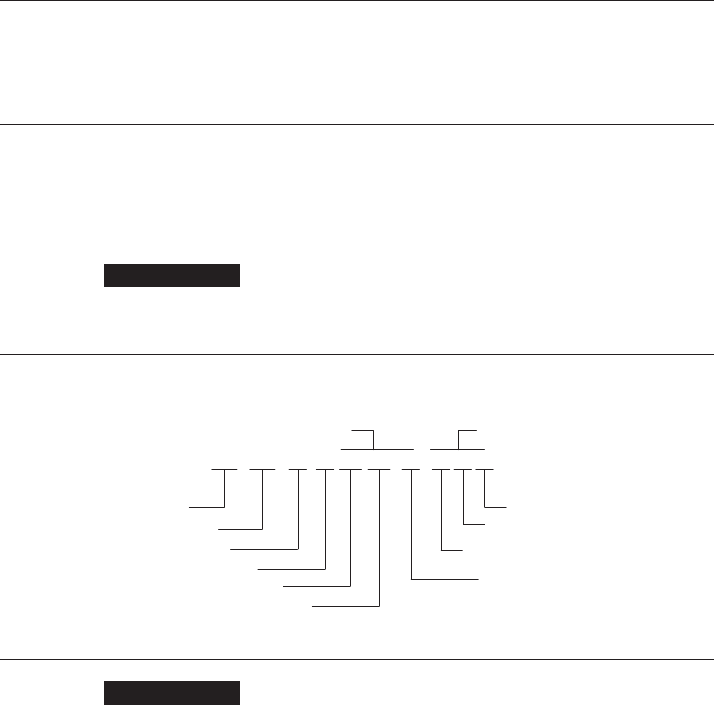

150 0 2 06- RH 21 EGBM

Rotation

Orientation Code

MODEL CODING

(Dwg. TPD1732)

For speci c models or special applications, contact your nearest Ingersoll-Rand Distributor or Ingersoll-Rand Engine Starting Systems,

Box 8000, Southern Pines, NC 28387 (910) 692-8700.

Installation

NOTICE

For maximum performance, read this manual prior to

installation or operation of Series 150BMG Starters.

General Information

1. This starter must be installed according to the instructions in this

manual.

2. Ingersoll-Rand recommends that on all vehicular installations and

on stationary engines subject to vibration, hoses of the specified

diameter be used instead of rigid pipe connections. Vehicle and

engine vibration will soon loosen rigid pipe connections, whereas

hoses will absorb the vibration, and connections will remain

tight.

3. When mounting a starter, make the hose connections at the

receiver and have the starter end of the hose handy for attaching

to the starter. Wherever possible, attach the air hoses to the

starter before mounting the starter on the flywheel housing.

There are two reasons for following this procedure:

a. After mounting the starter, it is often impossible to make hose

connections due to space limitations.

b. Once attached, the hoses carry some of the weight of the

starter, making it easier to complete the mounting.

4. Engine design often demands that the starter be mounted

underneath in extremely close quarters. Therefore, even though

two of the mounting bolt holes are easy to get at, the third

one is often difficult to reach. The tools usually needed in the

installation of a starter are a regular ratchet wrench, sockets,

universal joint, socket extension and a single or double-end

ratcheting box wrench.

5. The efficiency of a starter can be greatly impaired by an improper

hook-up. Hoses smaller than those recommended will reduce the

volume of air to the motor, and the use of reducers in the exhaust

port will restrict the exhaust and choke the motor. The use of tees

and elbows and the length of the supply line should be kept to

a minimum. In normal installations, hoses running from the air

tank to the starter should be No. 20 and fittings should be 1-1/4”.

Control hoses should be No. 4 and fittings should be 1/4”.

6. A leak in any of the connections means that the system will drain

overnight and will have to be repressurized the next morning

by using another vehicle or compressor. Make the connections

right the first time to avoid unnecessary costs and delays. On all

threaded connections throughout the system, use Ingersoll-Rand

No. SMB-441 Sealant, non-hardening No.2 Permatex,

Loctite®* Pipe Sealant or Perma-Lok® LH050**. Always run the air

supply line from the side or top of the receiver, never at or near

the bottom. Moisture will collect at the bottom of the receiver