03524832_ed12 13

Parts and Maintenance

NOTICE

The use of other than genuine Ingersoll Rand replacement parts may result in safety hazards, decreased starter performance, and increased

maintenance, and may invalidate all warranties.

Ingersoll Rand is not responsible for customer modi cation of starters for applications on which Ingersoll Rand was not consulted.

Repairs should be made only by authorized trained personnel. Consult your nearest Ingersoll Rand Authorized Service center.

When the life of the tool has expired, it is recommended that the starter be disassembled, degreased and parts be separated by material so that

they can be recycled.

Manuals can be downloaded from www.ingersollrandproducts.com

Refer all communications to the nearest Ingersoll Rand O ce or Distributor.

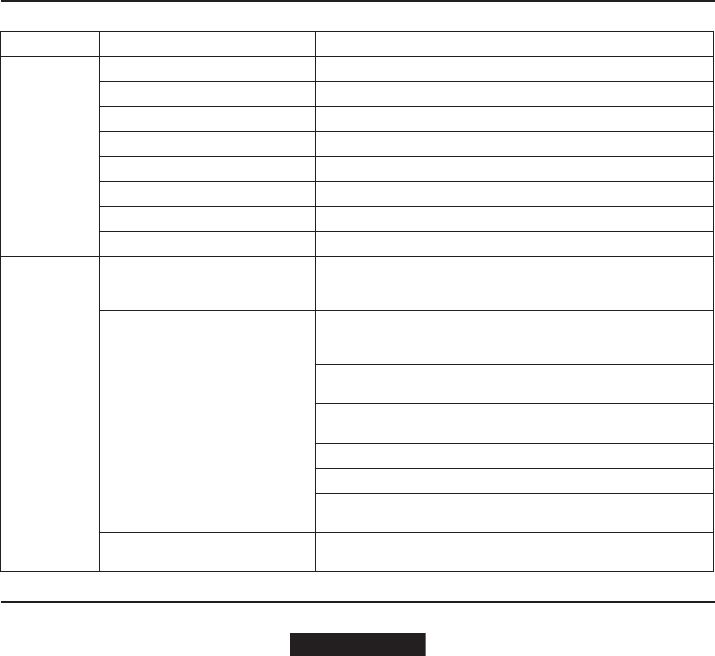

Troubleshooting Guide

Trouble Probable Cause Solution

Motor will not

run

No air supply Check for blockage or damage to air supply lines or tank.

Damaged motor assembly Inspect Motor Assembly and power train and repair or replace if necessary.

Foreign material in motor and/or piping Remove Motor Assembly and/or piping and remove blockage.

Blocked exhaust system Remove Housing Exhaust Cover (1) and check for blockage.

Defective Control Valve or Relay Valve Replace Control Valve or Relay Valve.

Low air pressure to Starter Check air supply.

Restricted air supply line. Check for blockage or damage to air lines.

Relay Valve malfunctioning Clean or replace lines or Relay Valve. Lube Relay Valve.

Loss of Power

Exhaust ow restricted Check for blocked or damaged piping. Clean or replace piping. Check for dirt

or foreign material and clean or remove. Check for ice build-up. Melt ice and

reduce moisture build-up to Starter.

Worn motor parts Remove the motor from the Motor Housing (14) and disassemble the

motor. Examine all parts and replace any that are worn or damaged. Use the

following guidelines for determining unserviceable parts:

1. Vanes (13): Install a new set of Vanes if any Vane is cracked, checked or

worn.

2. Rotor Bearings (8) or (37): Replace if any roughness or looseness is

apparent.

3. Rotor (40): Replace if there are any cracks or deep scoring.

4. Cylinder (11): Replace if there are any cracks or deep scoring.

5. End Plates (10) or (39): Clean up scoring by rubbing it with emery cloth

placed on a at surface.

Lack of air to starter Check for clogged or damaged air line between relay valve and starter.

Check relay valve to determine if it is functioning properly. Check air tank.