RUNNING GEAR ASSEMBLY —

PLATFORM AND CURTAINSIDE

TRAILERS

MOVEABLE SUSPENSIONS

1

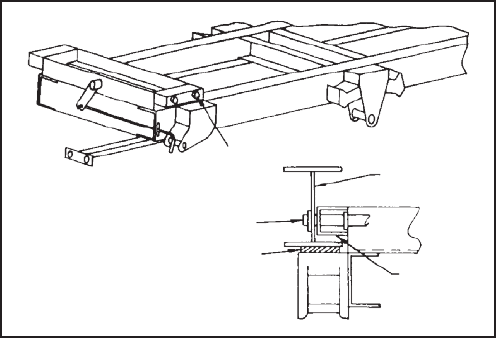

. Always check the condition of the locking holes

in the main beam. Holes that are badly worn or

elongated will result in undue slack in the slider

unit, causing excessive wear and suspension

misalignment.

2. Always check to see that the hold-down brackets,

denoted as (A) in the diagram below, are in good

repair and have not been damaged. Trailers should

not be operated if any of these brackets are not in

proper position.

3. Check the pin cage assembly bolts for tightness

after each year of service. Re-torque to 380 lb-ft.

FIXED SUSPENSIONS

1. If the trailer is equipped with a fixed suspension,

visually inspect all connections at regular intervals

to be sure there are no weld or fatigue cracks.

2. All cracks must be properly repaired and then

re-welded.

ALTERATIONS TO THE TRAILER

MINOR ALTERATIONS

These should be made in accordance with good shop

practices. Normally, minor alterations will not alter the

rating shown on the trailer certification plate. A possible

exception is the Gross Axle Weight Rating (GAWR).

The GAWR is the structural capability of the lowest-

rated member of the running gear components, sus-

pension and spring system, hubs, wheels and drums,

rims, bearings, brakes, axles, or tires.

If components are substituted that are of equal or

greater capacity than those used at the time of

manufacture, then the GAWR need not be altered.

I

f components are substituted that have less capacity

than those used at the time of manufacture, the GAWR

on the certification plate must be lowered to a corre-

sponding lower capacity.

MAJOR ALTERATIONS

No major alteration of a Great Dane trailer should ever

be made without first consulting the Great Dane factory.

Major alterations can affect the structural integrity

of the trailer, and can alter the GVWR and void the

trailer’s warranty coverage.

FEDERAL MOTOR CARRIER SAFETY

There are many regulations that govern the use and

safe loading of motor vehicles. These are user

requirements; therefore, they are your responsibility.

If information regarding these requirements is not

known to you or you need assistance, contact:

Federal Motor Carrier Safety Administration

Department of Transportation

Room 4223

400 – 7th Street, S.W.

Washington, D.C. 20591

or

the various states’ departments of transportation.

DURING EACH ANNUAL FMCSA VEHICLE

INSPECTION

It’s a requirement that all trailer structures be inspected

for weld or fatigue cracks and/or loose fasteners and

corrected to O.E.M. specifications before they are

returned to service. Upper slide rail to crossmember

attaching welds and pintle hook assembly welds must

be included during inspection.

26

LOCKING PINSHOWN

WITH PROPERPIN

E

NGAGEMENT

SLIDE PAD

HOLD-DOWN

BRACKET

MAIN BEAM

(A)

D

etail (A)

LOCKING PINAND HOLD-DOWNASSEMBLY