P/N: 4FM020-010

© 2003 Vortech Engineering, LLC

All Rights Reserved. Intl. Copr. Secured

20OCT03

v3.1 4.6/5.4Exped/Nav(4FM v3.1)

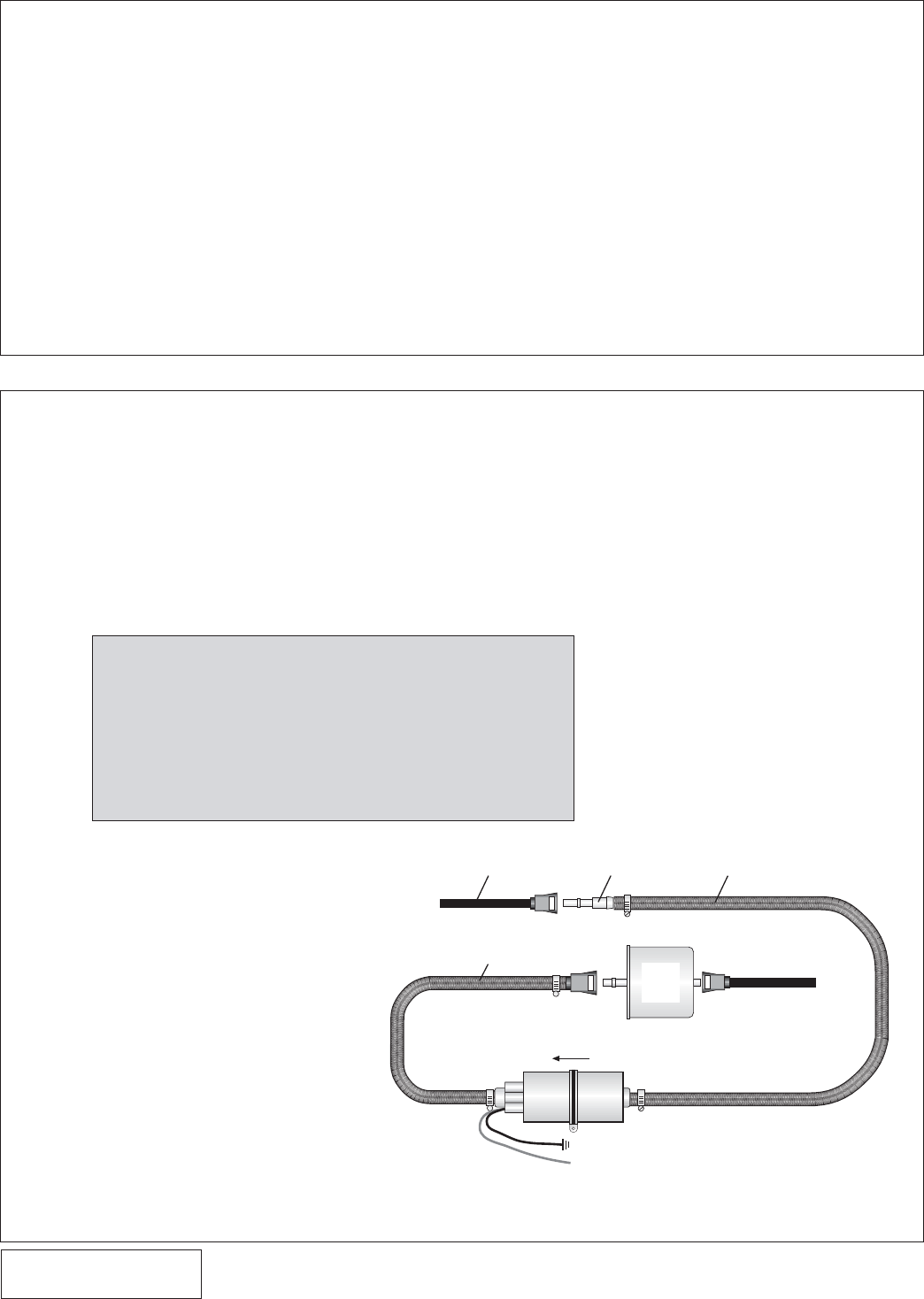

5. FUEL PUMP

A. Release any pressure from the fuel tank by momentarily loos-

ening the filler cap.

B. Disconnect the line from the tank to the fuel filter by carefully

removing the white retaining clip or by using a 3/8” springlock

disconnect tool, if equipped.

C. Connect the fuel pump inlet adapter fitting to the existing fuel

line coming from the fuel tank. Attach the supplied 1/2" inlet

hose to the adapter and pump inlet.

D. Connect the fuel pump outlet to the filter inlet.

6

5/16” HOSE

EXISTING FEED LINE

FROM TANK

(-) GROUND BLACK WIRE

CONNECT TO

(+) RELAY

TERMINAL (87)

STOCK

FUEL

FILTER

ADAPTER

FITTING

1/2” FUEL LINE

4. CRANKSHAFT PULLEY/SUPERCHARGER DRIVE PULLEY, cont'd.

NOTE: Due to the various fuel tank configurations and

frame rail lengths it will be necessary to find a

good mounting location near the fuel filter. Do

NOT mount the fuel pump close to exhaust heat

or to the bottom of the cab. The inside or the

outside of the frame rail will work well. Prior to

securing the fuel pump ensure the fuel lines will

not be kinked or pinched and are protected from

sharp edges.

E. Remove the installation tool and place the supercharger drive

pulley on the front of the harmonic balancer. Feeling for align-

ment, start the 12mm x 1.50 x 65mm center bolt with thick

factory washer and rotate the supercharger drive pulley until

the three bolt holes are aligned. Start the three 8mm x 1.25 x

25mm cap screws with washers, tighten all evenly beginning

with the center bolt (some applications may need two wash-

ers under each 8mm bolt head for thru-bolt clearance to the

engine front cover. Inspect behind balancer when tightening).

Torque the 12mm bolt to 80 ft/lbs and the 8mm bolts to 25 ft/

lbs.

F. Reinstall the inspection cover.

E. With the fuel pump in a position that

allows the lines to be routed loosely,

secure the fuel pump with the #12

hex screw.

F. Secure the pump inlet hose using

the supplied #8 clamps. Trim hose

length if necessary. Ensure that NO

kinks or sharp bends are allowed

on pump inlet hose or failure may

result.

G. Attach the negative pump terminal

to a clean ground. Scrape the ve-

hicle undercoat down to bare metal.

Fig. 5-a