2-14 Electrical

Section 2: Electrical

Splices and Repairs

For quality splicing and to reduce potential problems, the following guidelines are recommended:

• Stagger the splices within a harness to reduce increased harness diameter. Splice only on

straight areas as installed, not on bends.

• Strip wire ends making sure that individual conductor strands are not damaged.

• When soldering, make sure an adequate mechanical joint exists before applying solder. Use only

resin-core solder. Acid-core solder should not be used since it may result in corrosion.

• For crimp joints, use butt-type metal barrel fasteners and the correct tool at the appropriate

setting for the wire size (such as Motorcraft® Crimp Tool S-9796) specifically designed for this

type of work.

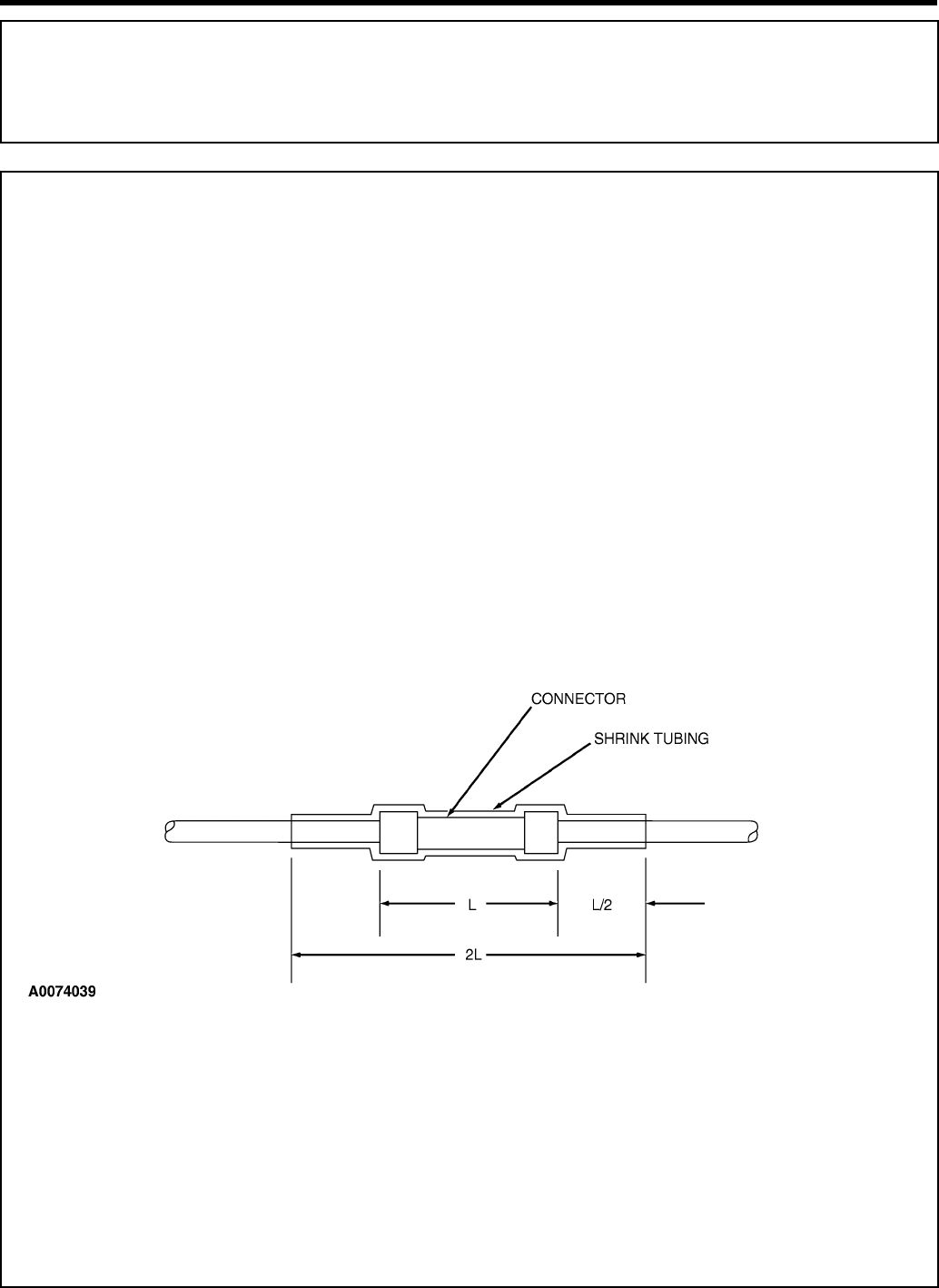

• Make sure splice joints are adequately sealed and insulated. In an outside environment, use

Duraseal butt connectors or equivalent. A durable substitute splice joint can be achieved by

using a bare metal barrel, crimping, flow-soldering and covering with shrink tubing. Quality

electrical tape can be used inside the vehicle, but is not recommended for an outside

environment.

• Be sure that the new wire is not a lesser gauge than its original mating wire.

Recommended Splicing Method — Solder (For 16 AWG and Smaller Diameter Wire

Only)

1. Disconnect the battery ground cable.

2010 Expedition SSV Modifiers Guide, 07/2009