1077 Actuator

Instruction Manual

Form 5605

March 2007

5

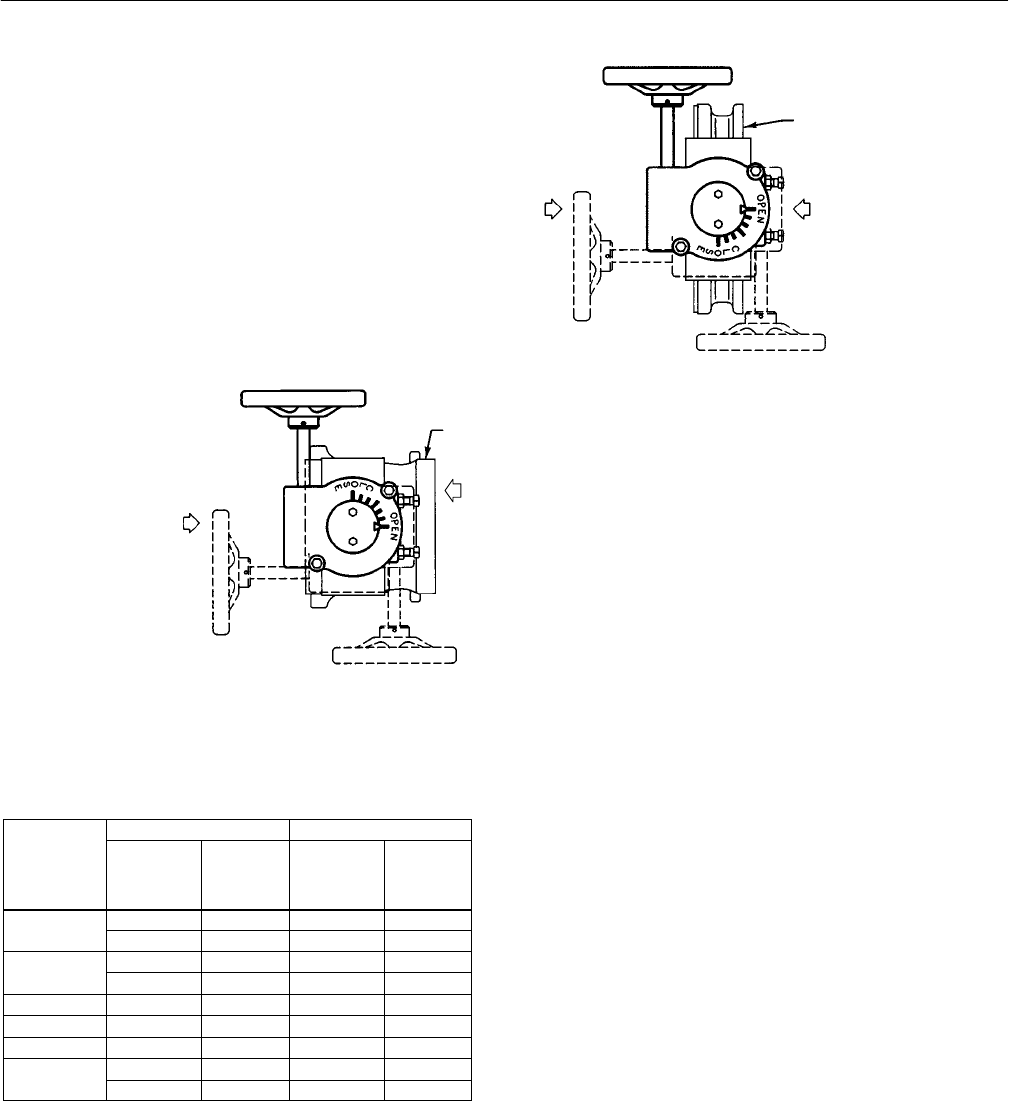

Figure 3. Available Mounting Positions

30B0668-A

B2002-3 / IL

DIRECT ACTING ACTUATOR CONSTRUCTION

REVERSE ACTING ACTUATOR CONSTRUCTION

FLOW DIRECTION

FOR LEFT-HAND

MOUNTING

POSITION 3

POSITION 1

POSITION 4

FLOW

DIRECTION FOR

RIGHT-HAND

MOUNTING

FLOW DIRECTION

FOR

LEFT-HAND

MOUNTING

VALVE BODY

FLOW

DIRECTION FOR

RIGHT-HAND

MOUNTING

POSITION 1

POSITION 3

VALVE BODY

POSITION 4

Table 3. Approximate Weights

METRIC UNITS U.S. UNITS

ACTUATOR

SIZE

Handwheel

Diameter,

mm

Weight of

Actuator

Assembly,

Kg

Handwheel

Diameter,

Inches

Weight of

Actuator

Assembly,

Pounds

0-KE

152 3.7 6 8

0-KE

203 4.7 8 10

2-KE

203 10.3 8 22

2-KE

305 11.3 12 24

6-KE 610 20.2 24 43

7-KE 762 28.2 30 60

9-KE 914 40.9 36 87

10-KE:6

432 62.6 16 133

10-KE:6

610 62.6 24 133

8. If removed for inspection, install the gearbox

cover plate. For a size 0-KE actuator only, also

install the O-ring onto the hub of the drive sleeve

gear.

9. Making certain that the travel indicator pointer is

aligned as it was prior to disassembly, install the

travel indicator.

10. Before installing the valve body and actuator in

the pipeline, perform the procedures presented in

the Adjustment section of this manual.

Adjustment

Perform the following steps to adjust the travel stops

and the travel indicator pointer. Individual part key

numbers and part descriptions referenced in this

procedure are shown in figure 6 except where

otherwise indicated.

Travel stops (key 10) consist of two set screws and

two hex nuts. For 90-degree valve disc or ball

rotation, both set screws are of equal length. For

60-degree disc or ball rotation, one set screw is

longer than the other. To change from 90-degree to

60-degree disc or ball rotation, one set screw must

be replaced with a longer one as explained below.