3024C Actuator

Instruction Manual

Form 5760

March 2007

5

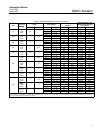

Table 4. Handwheel Specifications

ACTU-

ATOR

SIZE

HAND-

WHEEL

DIAMETER

TURNS PER

mm/INCH

TRAVEL

RIM

FORCE

(1,2)

HAND-

WHEEL

OUTPUT

FORCE

SIZE

mm In. mm In. N lb N lb

30 and

30E

200 7.87 0.24 6.1 179 40 5000 1125

34, 34E,

40, and

40E

250 9.84 0.21 5.4 286 64 10,000 2250

45 and

45E

250 9.84 0.21 5.5 400 90 14,000 3150

1. Tangential handwheel force required to produce the handwheel output force

shown.

2. Brass operating nut and stainless steel screw.

Installation

WARNING

Always wear protective gloves,

clothing, and eyewear when

performing any installation operation

to avoid personal injury.

Personal injury or equipment damage

caused by sudden release of pressure

may result if the actuator assembly is

installed where service conditions

could exceed the limits given in tables

1, 2, and 3 or the appropriate

nameplates. To avoid such injury or

damage, provide a relief valve for

overpressure protection as required by

accepted industry and governmental

codes and good engineering practices.

To avoid parts damage, do not use a

normal operating pressure that

exceeds the Maximum Diaphragm

Casing Pressure (see table 1) or

produces a force on the actuator stem

greater than the Maximum Allowable

Output Thrust (see table 2 or 3) or

Maximum Allowable Valve Stem Load.

Check with your process or safety

engineer for any additional measures

that must be taken to protect against

process media.

When ordered, the valve configuration

and construction materials were

selected to meet particular pressure,

temperature, pressure drop, and

controlled fluid conditions.

Responsibility for the safety of

process media and the compatibility of

valve materials with the process media

rests solely with the purchaser and

end user. Since some valve body/trim

materials combinations are limited in

their pressure drop and temperature

ranges, do not apply any other

conditions to the valve without first

contacting your Emerson Process

Management sales office.

If installing into an existing

application, also refer to the WARNING

at the beginning of the Maintenance

section in this instruction manual.

A Type 3024C diaphragm actuator is normally

shipped mounted on a valve. Refer to the

appropriate valve instruction manual when installing

the valve in the pipeline. If the actuator is shipped

separately or if it is necessary to mount the actuator

on the valve, perform the Actuator Mounting

procedure given below. For information on mounting

the positioner refer to the appropriate positioner

instruction manual.

CAUTION

The Type 3024C actuators are

designed to mount on push-down-

to-close valves. Do not mount these

actuators on any other type of valve

without first contacting your Emerson

Process Management sales office.

Mounting the Actuator on the Valve

The following procedure describes how to mount a

Type 3024C actuator on a push-down-to-close valve

so that the actuator stem and valve stem thread

engagement allows full travel and proper shut-off.

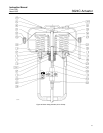

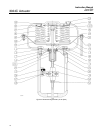

Refer to table 4 and figures 6 and 7 for actuator