©2003 Edelbrock Corporation

Brochure No. 63-0148

Rev. 2/03

Page 12 of 23

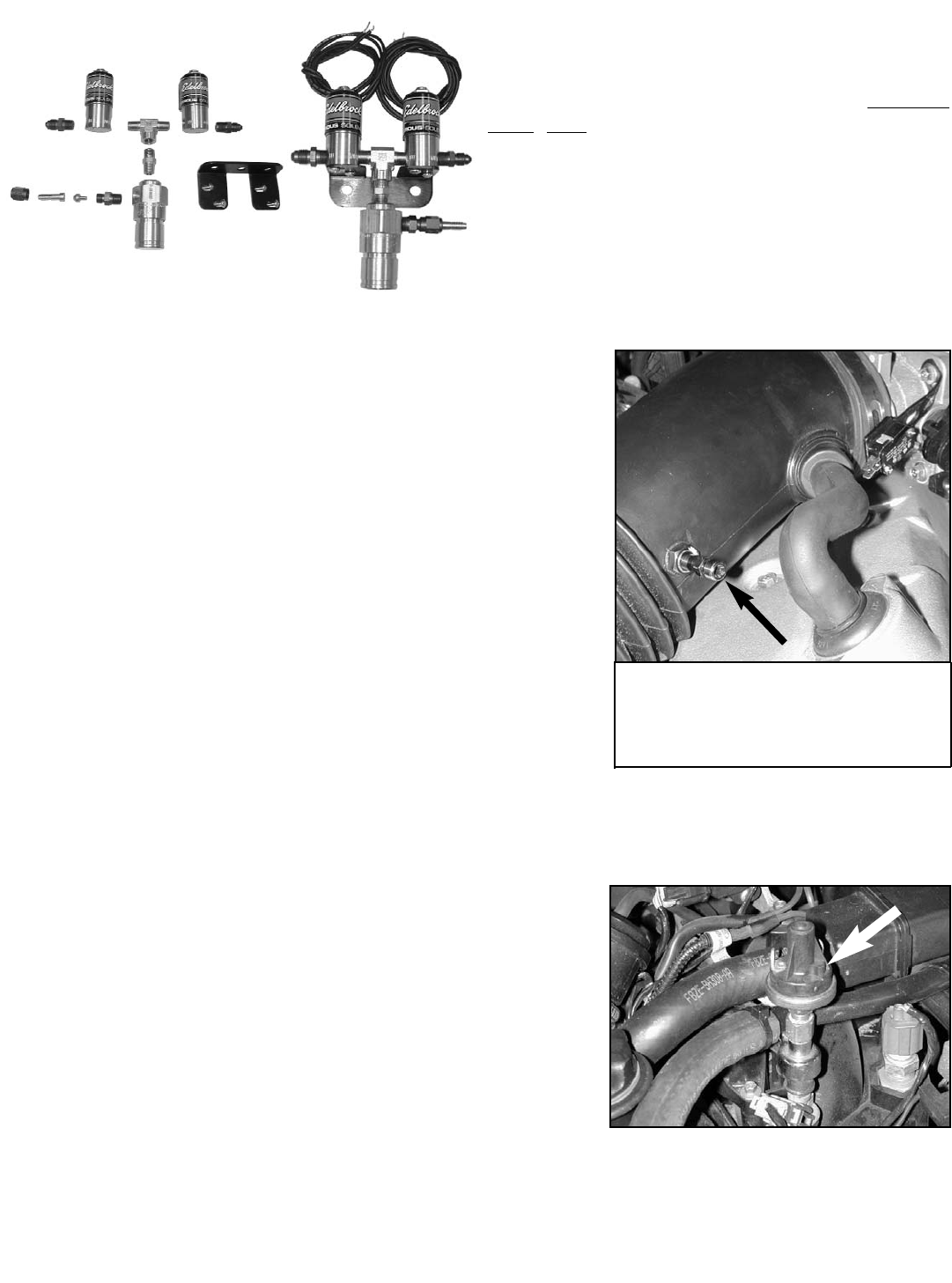

Shown to the far left is a layout of the solenoid assembly with all

of the components that are required for this procedure. Shown

directly to the left is the finished assembly. Be sure that when

you are using thread sealant on any fittings that you Do not use

Teflon

®

Tape. Only use Teflon

®

Paste. Teflon tape can break off

small pieces within the fittings that could potentially clog the

nitrous or fuel jets resulting in system failure.

The line length between the Performer 4.6L Mustang solenoid

assembly and the jet fitting on the nitrous spray nozzle is 24

inches. This should also be considered when mounting the

solenoid assembly.

2.6 Nitrous Spray Nozzle Installation

1. Determine nozzle mounting location in intake boot, between

the MAF sensor and the throttle body. Make sure the nozzle,

mounting collar, and the feed line from solenoid to nozzle, do

not interfere with any systems or components of the vehicle

such as the hood.

2. Mark where the nozzle will be placed.

3. Remove the intake boot.

4. Drill a 7/16” hole in the intake boot where nozzle placement

was determined.

5. Be sure to clean out the rubber shavings you made when

drilling to prevent engine damage.

6. Install nozzle mounting nut and collar onto intake boot.

7. Using liquid Teflon

®

, install the spray nozzle into mounting

collar.

8. Mark the spray direction on the nozzle. Be sure the nozzle

discharge is towards the vehicles engine.

9. Install the .032 or .036 jet into the nozzle fitting.

10. Install 3AN line from solenoid outlet fitting to spray nozzle jet fitting and tighten securely.

11. Install the intake boot.

2.7 Fuel Pressure Safety Switch Installation

1. Locate the fuel rail test port fitting.

2. Make sure the vehicle’s engine is cool. Release pressure in

the fuel system by pressing down on the valve in the center

of the fitting. This will allow the pressure to escape as well

as some fuel.

3. After relieving all pressure, remove test port fitting core and

install the 1/16 NPT male X 1/8 NPT female brass fitting in

its place, using liquid teflon

®

paste.

4. Using liquid Teflon

®

paste, install Fuel Pressure Safety

Switch into the 1/8 NPT female adapter end.

Note: On some vehicles, there is no test port fitting, or the

location of the test port fitting does not allow ample room for the fuel pressure safety switch to be mounted.

These applications will require a “Banjo Nut” at the fuel filter to be drilled and tapped to allow mounting of the

safety switch.

Nozzle should be placed in the intake boot so as

to have a clear path to the throttle body. Try to

keep the nozzle from having to travel through the

bend in the intake boot and as close to the

throttle body as possible.