PIT BOSS

Users Manual

17

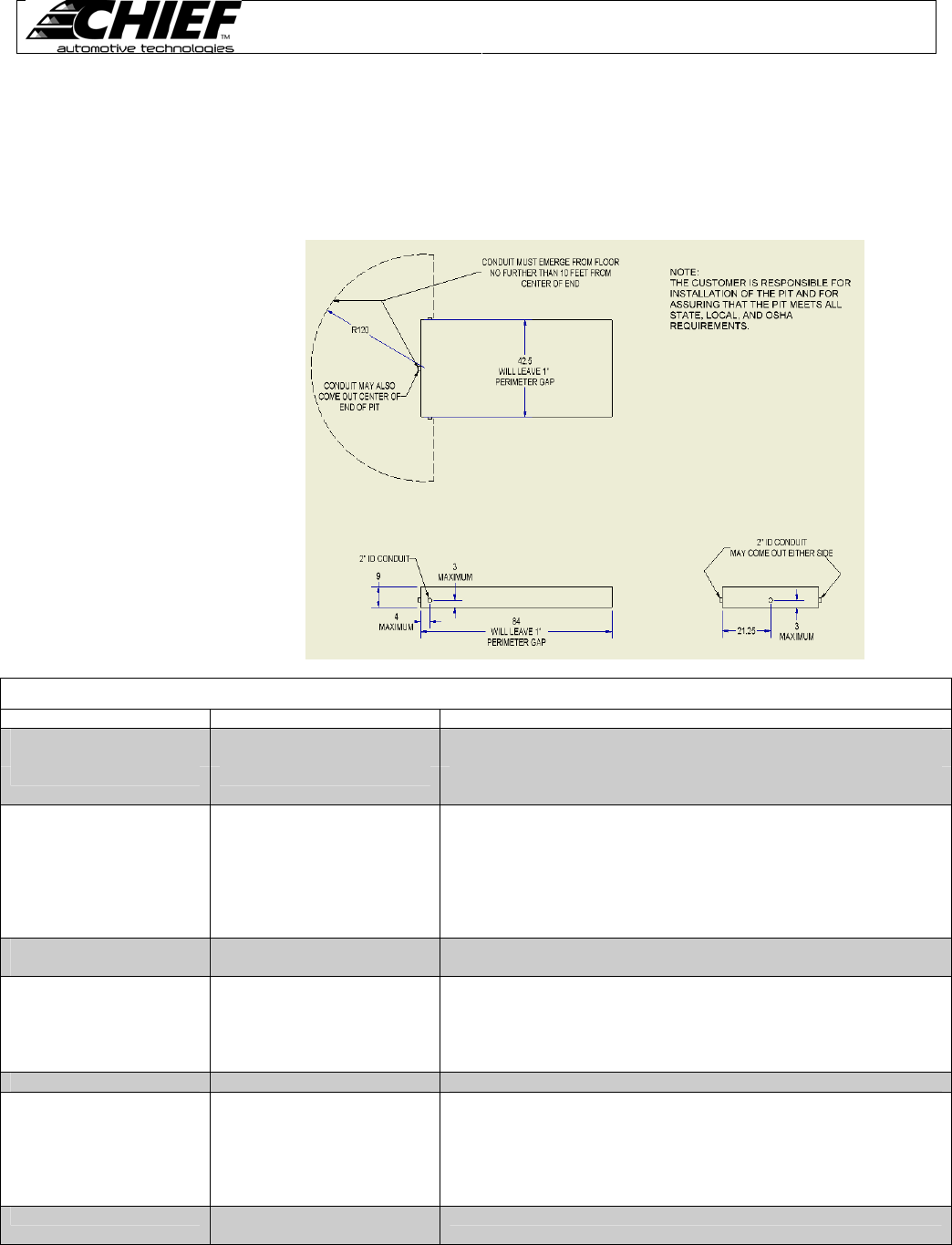

Machine Pit Layout

The PIT BOSS is designed specifically for use in a flush mount pit. Figure 39 shows the pit dimensions. For maximum

effectiveness it is essential that the hydraulic and air lines be run in conduit under the surface of the floor. The conduit should

be 2” inside diameter and must be acceptable for the use with concrete. Where ever the conduit emerges will mark the

location of the pump and stand. Be certain this is an acceptable area clear of traffic. The profile of the PIT BOSS and

accessories is shown in Figure 26. Placement of the pit should take into account these accessories plus additional space

needed for a comfortable work area.

Figure 39

Troubleshooting

PROBLEM CAUSE

POSSIBLE SOLUTION

Pump will not Run Air supply disconnected Plug in air supply

Air supply not energized Turn on air supply

Bad pump Replace pump. Contact Chief Automotive Service Representative

for replacement.

Pump will not build

pressure or builds

pressure slowly

Hydraulic fluid low Fill fluid reservoir to within 1” (25 mm) of top with SUS215 viscosity

@ 100°F (38C) 10W hydraulic oil with all cylinders down and

machine in loading position.

Contamination in fluid Remove and clean fluid. Contact Chief Automotive Service

Representative.

Contamination in cylinders Remove and inspect cylinders. (Refer to parts manual). Contact

Chief Automotive service representative.

Pump will not hold

pressure

Hydraulic oil leak Check hoses, fittings, cylinders, and quick couplers for leaks.

Tighten or replace if necessary

Pump stalls or will not

start under pressure

Contamination in fluid Remove and clean elbow fittings at cylinders. Contact Chief

Automotive Technologies Service Representative.

Too much weight

Insufficient air supply

Maximum total lift capacity (including 2000 lb Shop Hopper) is 8500

lbs.

Use different air supply.

Tower cylinder jumps Air in hydraulic system Bleed hydraulic system

Tower cylinder will not

extend

Auxiliary line valve closed Open auxiliary line valve one turn

Auxiliary line not connected

to tower

Connect auxiliary line to tower

Lift switch turned on Turn off lift switch

Pump will not build pressure See pump problems above

Collars jump under load Improper fit between collar

and tower pipe

Refit collar – Contact Chief Automotive service representative.