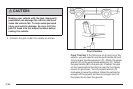

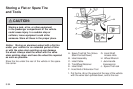

{CAUTION:

Incorrect or improperly tightened wheel

nuts can cause the wheel to come loose and

even come off. This could lead to a crash.

If you have to replace them, be sure to get

new original equipment wheel nuts. Stop

somewhere as soon as you can and have the

nuts tightened with a torque wrench to the

proper torque specification. See Capacities

and Specifications on page 5-115 for wheel

nut torque specification.

Notice: Improperly tightened wheel nuts can

lead to brake pulsation and rotor damage.

To avoid expensive brake repairs, evenly tighten

the wheel nuts in the proper sequence and to

the proper torque specification. See Capacities

and Specifications on page 5-115 for the wheel

nut torque specification.

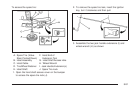

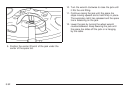

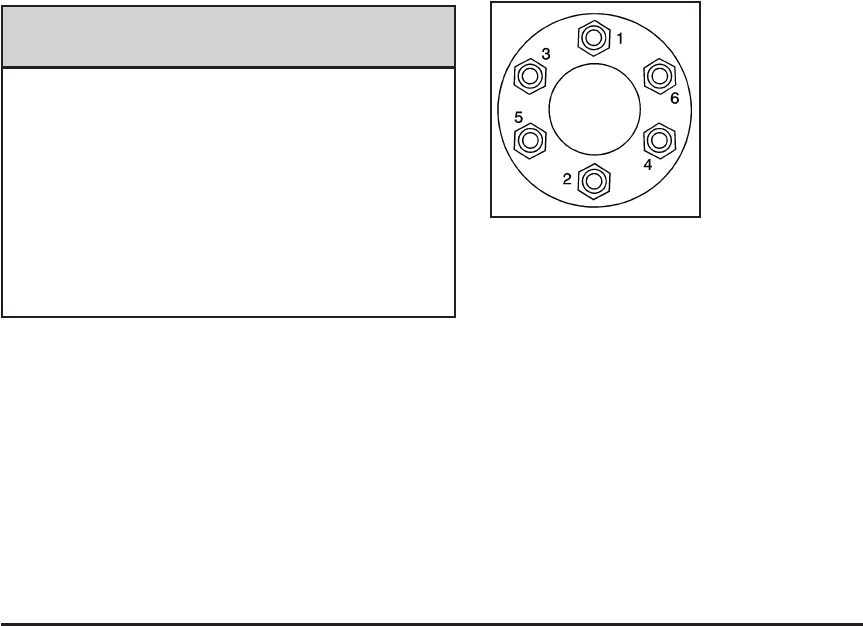

12. Tighten the

nuts firmly in a

crisscross sequence

as shown by

turning the wheel

wrench clockwise.

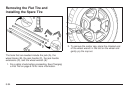

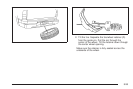

When you reinstall the regular wheel and tire, you

must also reinstall the center cap. Line the tab on the

back of the tab with the slot in the wheel. Place the

cap on the wheel and press until it snaps into place.

5-89