Source – Volvo AB, Göteborg, Sweden page 20(35)

Reprint 2001 Karl Eric Målberg

reason it must be changed at regular intervals, after about every 6,000 miles

(10,000km). This operation should preferably be carried out by a Volvo workshop.

If the oil cleaner is changed without the engine oil being changed, 0.5 litres should be

added to the engine.

12 Valve clearance

Let your Volvo workshop check the engine valve clearance after every 3,000 miles

(5,000 km). Excessively small valve clearance can easily cause burned valves.

13 Clean the fuel filter

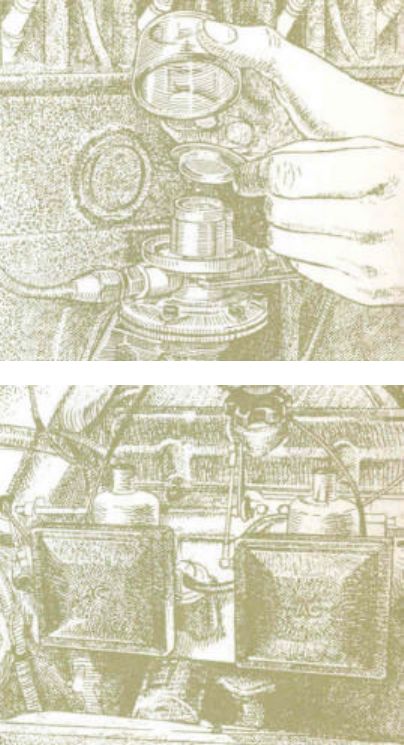

In order to avoid dirty fuel from being

pumped into the carburettors, the fuel

filter should also be serviced. Due to the

accessible location of the filter, it is very

easy to clean.

The fuel filter should be cleaned after

every 3,000 miles (5,000 km). Loosen

the nut and move the bail to one side.

Remove the glass bowl and strainer and

clean these parts. When the filter is being

re-fitted, male sure that the gasket seals

properly

14 Change the air cleaners

The air cleaners on the SU carburettors

should be replaced with new units after

every 12,500 miles (20,000 km). The old

unit should be thrown away since the

cleaner and the filter are built together in

one unit. When driving on dusty roads, it

may be advisable to change the air

cleaners more often, for example every

6,000 miles (10,000km)

NOTE. The ventilation air to the lower

part of the carburettor suction chambers,

passes the air cleaner through the two

upper holes in the cleaner so it is

important to see that the gasket and

the air cleaner are fitted correctly in each case, since otherwise theses holes will be

blocked

15 Check the fan belt tension

After about every 6,000 miles (10,000km) you should let your Volvo Workshop check

that the fan belt tension is correct. Due to wear or dirt, this belt can start slipping and

the result will be poor cooling and poor generator output. You can easily check the

tension by pulling the tips of the fan in their correct direction of rotation. There should

be a definite resistance to movement (at a pulling power of 12-14 lb= 5.5-6.5 kg).

before the belt starts slipping. A simple but not so reliable way of testing belt tension

is to press the fan belt with your thumb at a point midway between the generator and

the fan. It should be possible to press down the belt about 1/6” = 3-4 mm with normal

thumb pressure.