FUEL SYSTEM AND GOVERNOR

55

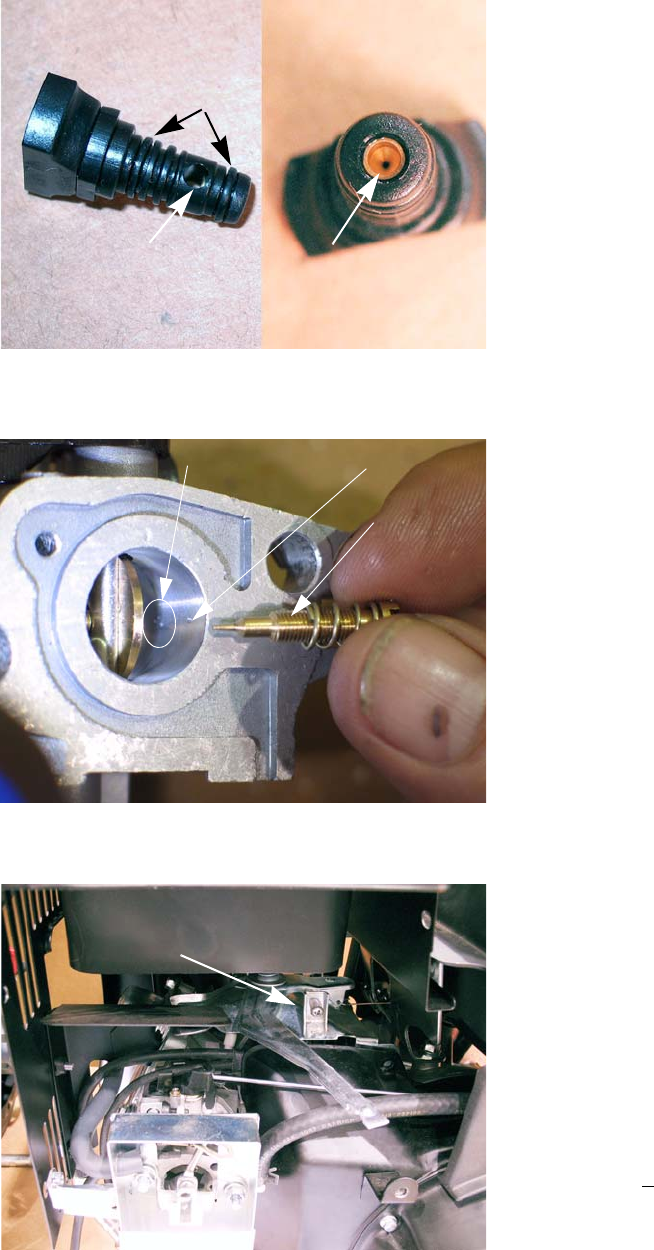

12. Examine the metering plug: See Figure 4.33.

• Fuel, drawn from the central column via the long

fuel feed leg, is metered by the brass orifice in the

tip of the metering plug.

• Air, drawn from the emulsion air port, is metered by

the size of the brass orifice at the entrance to the

port.

• The fuel and air that feed the pilot and transition

ports are mixed at the metering plug.

• The metering plug creates a small venturi. The

pressure drop of the air passing through the meter

-

ing plug draws the fuel into the passage to the pilot

and transition ports, in an emulsified mixture.

NOTE: The pilot screw regulates how much of this pre-

mixed fuel/air emulsion is allowed to enter the

throat of the carburetor, to atomize down-stream of

the throttle plate. On current production units, it is

set at the factory and the screw head is removed.

See Figure 4.34.

NOTE: The transition ports are fixed. They are drilled into

the throat of the carburetor, down-stream of the

venturi. They lie behind the brass welch plug near

the pilot screw.

13. Soak the Carburetor body in a suitable solvent until

clean.

NOTE: Ultrasonic cleaning using a suitable water/deter-

gent mixture will clean carburetors safely and

effectively.

14. Rinse it thoroughly.

15. Dry the carburetor body using compressed air.

16. Reassemble the carburetor and install it by following

steps 1-8 in reverse order.

17. Start the engine and check the idle RPM using a

tachometer.

18. Check the top no load speed of the engine.

NOTE: The top no-load speed of the engine is 3500

RPM’s

+ 100.

19. The top no-load speed is easily adjusted by tighten-

ing/loosing the speed adjustment screw. Tighten the

screw to decrease speed and loosen it to increase

speed.

See Figure 4.35.

Figure 4.33

Air passage

O-rings

End view

Fuel metering orifice

Figure 4.34

Transition ports Pilot port

Pilot screw

(before head

is removed)

Figure 4.35

Adjustment screw

For Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com