10

Oxidation (ASTM D-943) 1000 Hours Minimum

Pump Wear Test (ASTM D-2882) 60 mg Maximum

The following uids work well over a wide temperature

range, allow moisture to settle out and resist biological

growth that may occur in cool operating hydraulic circuits.

These uids are recommended by Stanley. Other uids

that meet or exceed the specications of these uids may

also be used.

Chevron AW-MV-32

Exxon "Univis" J-26

Mobil D.T.E. 13

Gulf "Harmony" AW-HVI-150-32

Shell "Tellus" T-32

Texaco "Rando" HD-AZ

Union "Unax" AW-WR-32

Terresolve EnviroLogic 132

4. HYDRAULIC CONNECTIONS

The recommended hose length is 25 ft/8 m with a 1/2

inch/12.7 mm inside diameter. The hoses must have a

working pressure rating of at least 2500 psi/175 bar. Each

hose end must have male thread ends compatible with

H.T.M.A. (HYDRAULIC TOOL MANUFACTURERS AS-

SOCIATION) quick disconnect ttings (NPT type threads).

(See Page 8.)

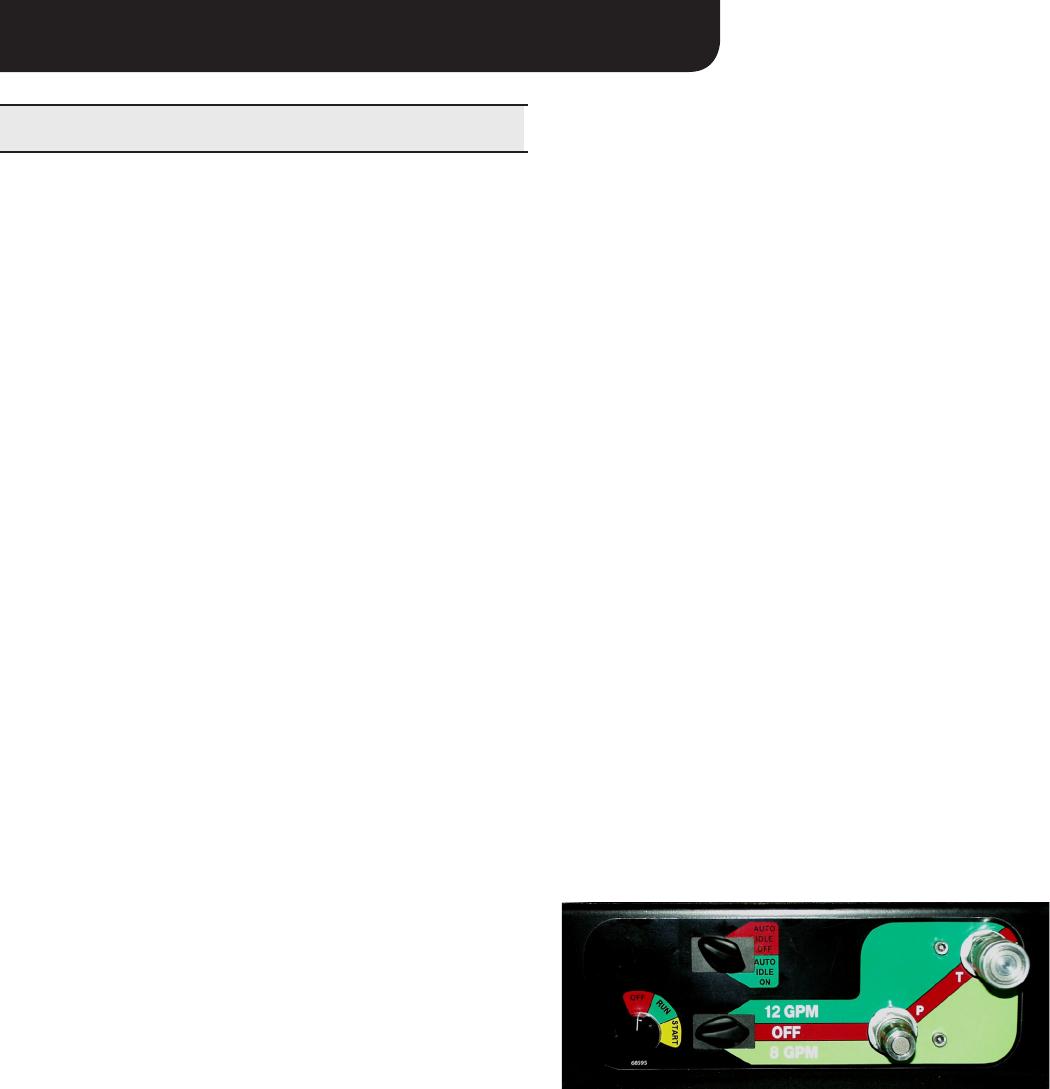

Figure 1. Panel Control Valve

Facing the panel control valve, the bottom male quick

disconnect tting is the PRESSURE FLUID OUT tting. The

top female quick disconnect tting is the RETURN FLUID

IN tting.

QUICK DISCONNECT COUPLERS

H.T.M.A. approved quick disconnect couplings are installed

to hydraulic hoses so that the direction of oil ow is always

from the male to the female quick disconnect as shown on

page 8. Quick disconnect couplings and hose ttings are

PREPARATION FOR USE

Do not operate the power unit until you have read the

engine operating and maintenance instructions manual

furnished with the unit.

1. ENGINE CRANKCASE OIL LEVEL

Always check the oil level before starting the engine. Make

sure the oil level is at the FULL MARK on the dipstick. Do

not overll. Use detergent oil classied "For Service SE, SF,

SG" as specied in the engine operating and maintenance

manual. See engine manual for oil viscosity grade.

2. SPARK PLUG

On power units equipped with Briggs & Stratton Engines,

ONLY Champion RC12YC or equivalent can be used.

Incorrect type spark plugs can produce radio frequency

interference that will corrupt and damage the controller.

Failure to use the correct spark plug could result in a war-

ranty that will not be considered.

3. ENGINE FUEL LEVEL

Check the fuel level. If low, ll with un-leaded gasoline with

a minimum of 85 octane.

4. HYDRAULIC FLUID

Check the dip stick in the hydraulic uid reservoir for the

proper uid level. Use uids meeting the following speci-

cations.

Viscosity (Fluid Thickness)

U.S. METRIC

50°F 450 SSU Maximum 10°C 95 C.S.

100°F 130-200 SSU 38°C 27-42 C.S.

140°F 85 SSU Minimum 60°C 16.5 C.S. Min

Pour Point -10°F/-23°C Minimum (for cold startup)

Viscosity Index (ASTM D-2220) 140 Minimum

Demulsibility (ASTM D-1401) 30 Minutes Maximum

Flash Point (ASTM D-92) 340°F/171°C Minimum

Rust Inhibition (ASTM D-665 A & B) Pass

OPERATION