16 ► CD12 User Manual

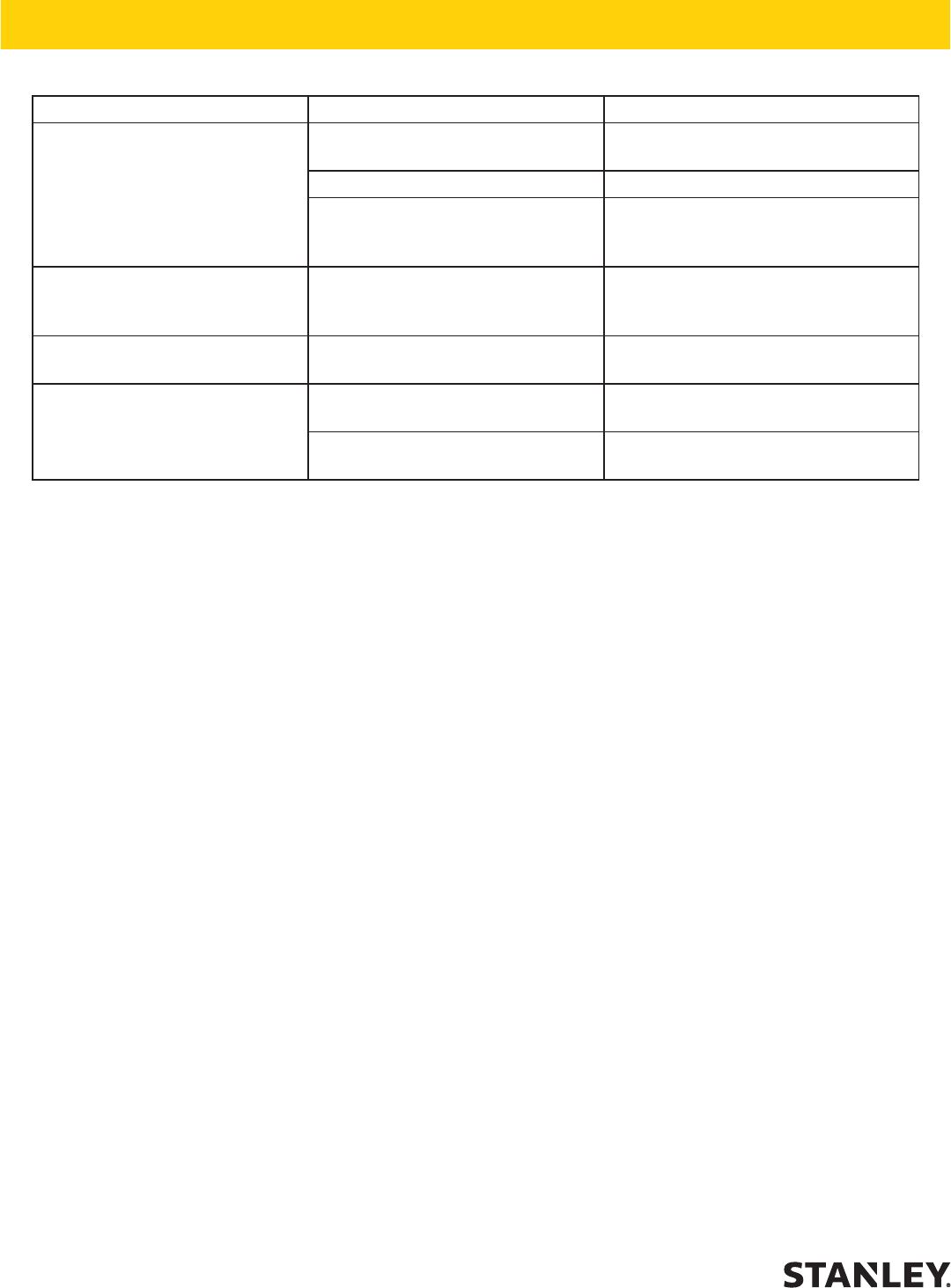

Problem Cause Solution

Fluid gets too hot. Circuit relief set too low. Adjust relief valve to 2100-2250/145-

155 bar.

Too much uid going through tool. Adjust ow for 6 gpm/23 lpm maximum.

Circuit has contaminants that have

caused wear and high heat genera-

tion.

Replace worn pump and valves. Install

a large clean lter and keep the uid

clean.

Gear shift knob turns hard. Oil leak at motor shaft seal into gear-

box causes high pressure in gear-

box.

See your authorized service dealer for

repair.

No gearshift function. Shifter pin worn or broken. See your authorized service dealer for

repair.

Water leaking out of shaft. Output shaft seals worn. See your authorized service dealer for

repair.

Water pressure too high. Seal dam-

aged.

Maximum water pressure 60 psi/4 bar.

Replace seals.

MAINTENANCE

Good maintenance practice keeps the core drill on the

job and increases its service life.

The most important maintenance practice is to keep

the hydraulic uid clean at all times. Contaminated uid

causes rapid wear and/or failure of internal parts.

Follow the recommendations contained in the HYDRAU-

LIC SYSTEM REQUIREMENTS section of this manual

to ensure peak performance from the tool.

Do not disassemble the tool until you know whether the

problem is in the hydraulic power supply, the gearbox

module, or the power and control (rear) module. Then

only disassemble the tool as necessary to repair as re-

quired. KEEP CONTAMINANTS SUCH AS DIRT AND

GRIT AWAY FROM INTERNAL PARTS AT ALL TIMES.

Always determine and correct the cause of the problem

prior to reassembly. Further wear and tool failure can

result if the original cause is not corrected.

TROUBLESHOOTING