13

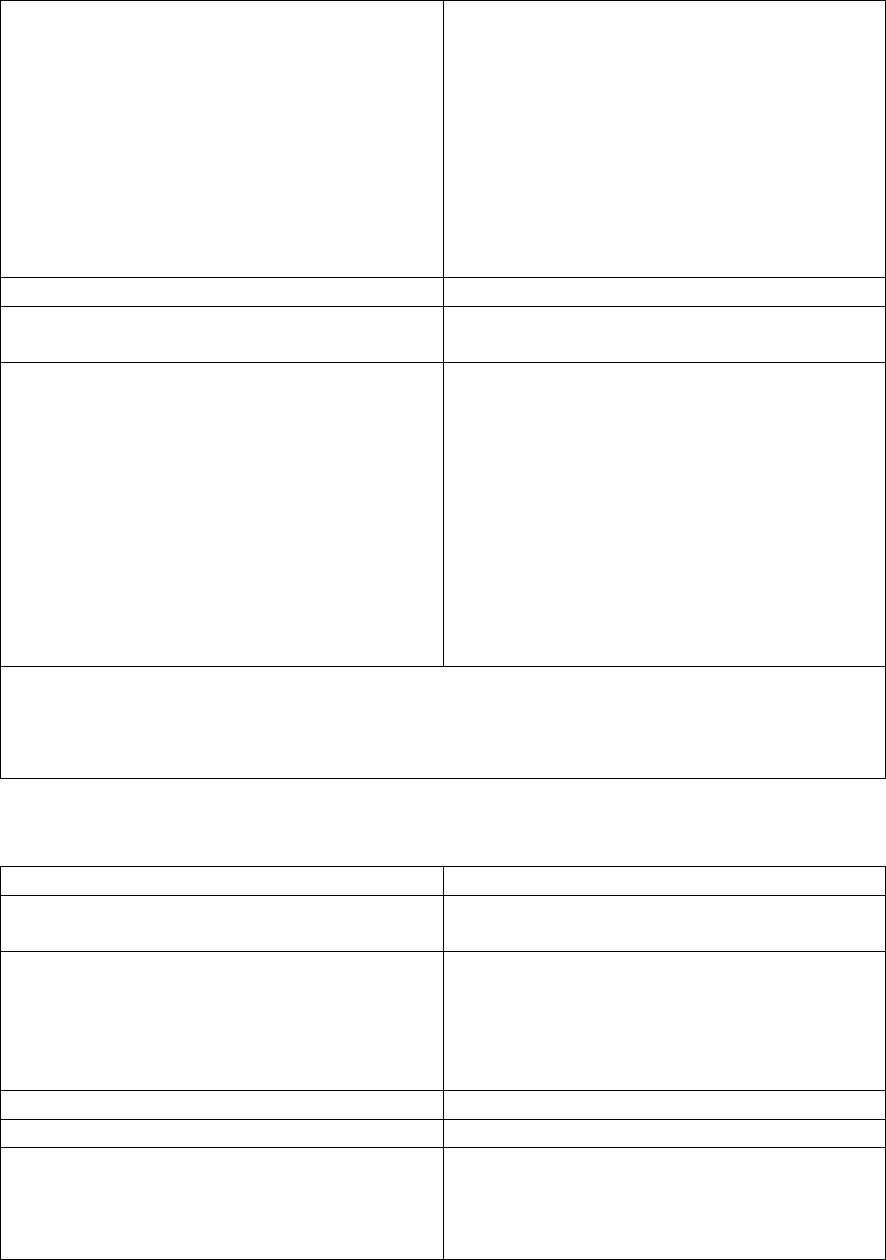

Fuel Injection

Valves

1. Verify the operation of each injection

valve by disconnecting the electrical

supply to each injection valve, one at a

time and determine if the engine speed

drops when the valve is disconnected.

2. If the speed drops, the valve is

defective.

3. Measure the resistance of the coil of

each injection valve. Should be 2-3

ohms.

Fuel Pressure

Verify the fuel pressure is correct.

Air Flow

Sensor

Verify the air flow sensor is functioning

properly.

Temperature

Sensor II

1. Measure the output of the

temperature sender unit under various

conditions. Following values should be

used for reference purposes, but the

value may be different due to the age

of the sensor.

Temperature Range Value

68

0

F 2k – 3k ohms

14

0

F 7.5k – 12k ohms

176

0

F 250 – 400 ohms

Note (1): Activated charcoal filter hose must be disconnected at air cleaner, the

air injection hose must be removed and the check valve must be plugged. The

adjustments should be made as quickly as possible to prevent excessive heat in

intake lines.

ACCELERATION NOT SMOOTH

Possible Problem Procedure

Throttle Valve

Switch

1. Verify function of throttle valve.

Air Intake

System

1. The air intake system must be free

of leaks. Check the intake manifold,

hoses and associate components with

soapy water to determine if leaks are

occurring.

Auxiliary Air Device

1. Verify function of auxiliary air device.

Air Flow Sensor

1. Verify function of air flow sensor.

Exhaust Gas Mixture

1. If the concentration is too high,

adjust the bypass screw in the air flow

sensor ½ turn counterclockwise and

measure again.