Accessories for HLE and HLEZ

Automation

28

Parker Hannifin GmbH

Electromechanical Division

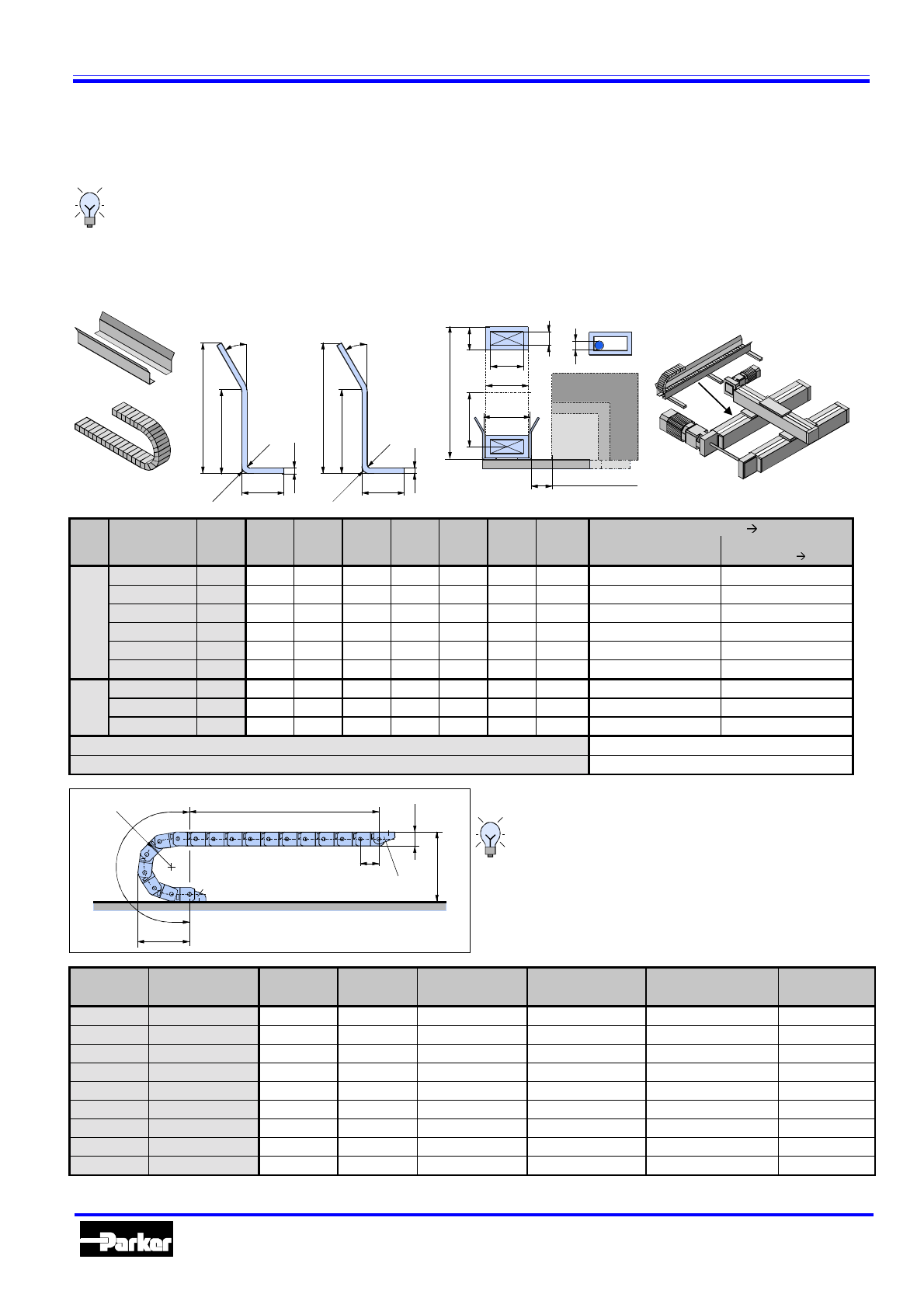

Cable carrier

A cable carrier is needed when making power connections to moving elements. The cable carrier chain consists of glass fibre

reinforced polyamide, and the support profile is made of aluminium.

The process for fully determing the dimensions of a cable carrier is very complex. The examples listed below represent

simple applications, but more data will normally be required when the situation is less straightforward.

The following

descriptions only apply to power supplies arranged horizontally, which lie above a support profile and which

are within the limits specified in the technical data

. If the application you are running is more demanding, please

contact us.

Dimensions of support profile and cable carrier chain

3

24

73

48

R2

R4

30°

4

60

135

107,1

R4

R6

30°

KSP 1

KSP 2

HLE150

HLEZ150

HLE(Z)100

HLE80

KR

F

E

D

B

C

A

d

customized

Art. no.

(For lengths

page 30)

Type CR A B C D E F

d

max.

Cable carrier chain

2 x connection angle

(for dimensions

page 29)

0.320.20 37

13 24 29 103 25 19 11 100-906000 100-906100

0.320.42 37

24 35 40 103 25 19 16 100-905800 100-906110

0.450.21 52

38 54 59 147 40 24 22 100-905900 100-906090

0.450.21 94

38 54 59 231 40 24 22 100-906200 100-906090

0.450.41 94

58 74 79 231 40 24 22 100-906300 100-906095

with

KSP1

0.450.61 150

78 94 99 343 40 24 22 100-906310 100-906350

0.625.25 200

65 93 98 459 62 42 31 100-906505 100-906506

0.625.45 200

108 136 141 459 62 42 31 100-906510 100-906506

with

KSP2

0.625.45 300

108 136 141 659 62 42 31 100-906530 100-906506

KSP1

Small cable support profile (specify length required, equal to travel lenght) 400-010120

KSP2

Large cable support profile (specify length required, equal to travel lenght) 400-010121

L

S

/2

t

h

G

H

L

B

KR

Fix point

Drivin

g

plate

Ü

B

Dimensional drawings of connection points

(fix point and driving plate):

Page 29

Bending radius Pitch Height Curve length Curve protrusion Connection height Own chain

Type KR

t h

G

L

B

Ü

B

H

min

(= 2KR+hg)

weight kg/m

0.320.20 37

32 25 181 82 99 0.32

0.320.42 37

32 25 181 82 99 0.39

0.450.21 52

45 40 254 117 144 0.75

0.450.21 94

45 40 386 159 228 0.75

0.450.41 94

45 40 386 159 228 0.85

0.450.61 150

45 40 562 215 340 0.92

0.625.25 200

62.5 62 754 290 456 1.35

0.625.45 200

62.5 62 754 290 456 1.50

0.625.45 300

62.5 62 1068 390 656 1.50