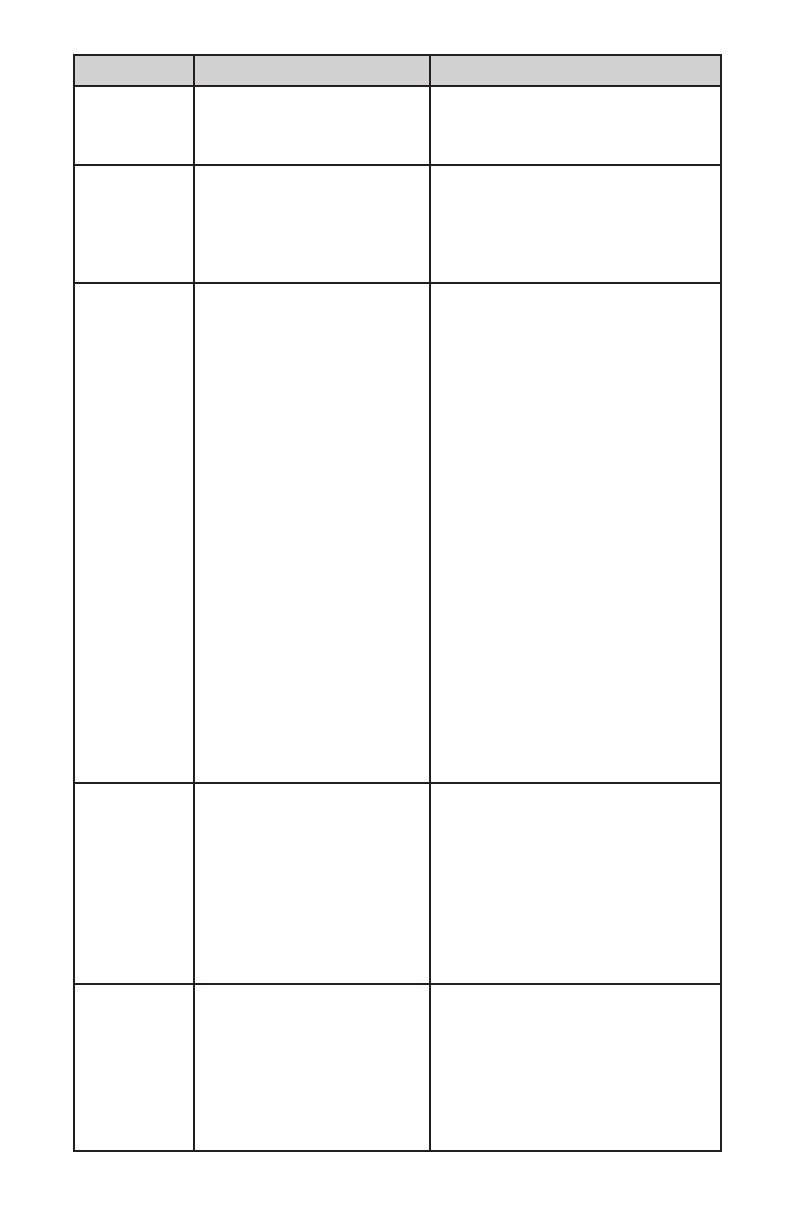

21

REMEDY

locate and correct

return to factory for replacement

return to factory for replacement

locate and repair

use matched calibration

see K factor tables in APPENDIX 2

locate and correct

return to factory for replacement

flush clean or disassemble to remove

impediments

flush clean or disassemble to remove

impediments or return to factory for

replacement

flush clean or disassemble to remove

impediments or replace

check for any tilt or change in the

mounting of the transducer; generally,

units are calibrated for horizontal

installation (relative to the sensor tube)

re-adjust valve (section 7.4)

return to factory for replacement

check cable and connectors or replace

decrease pressure to correct level

adjust appropriately

re-adjust valve (section 7.4)

return to factory for replacement

check cable and connectors or replace

disassemble to remove impediments

or return to factory

LIKELY REASON

gas leak

pc board defective

defective sensor

gas Leak

gas metered is not the same as

what meter was calibrated for

composition of gas changed

gas leak

pc board defective

RFE dirty

occluded sensor tube

filter screen obstructed at inlet

transducer is not mounted

properly

incorrect valve adjustment

pc board defect

cable or connectors malfunction

differential pressure too high

insufficient inlet pressure

incorrect valve adjustment

pc board defect

cable or connectors malfunction

orifice obstructed

INDICATION

unstable or no

zero reading

full scale out-

put at "no flow"

condition or

with valve

closed

calibration off

FMA 1400

valve

does not work

in open

position

FMA 1400

valve does not

work in close

position