PAGE 22 — MQD2H/3H DIAPHRAGM PUMPS — OPERATION AND PARTS MANUAL — REV. #7 (05/24/13)

Rotation of Suction and Discharge Ports

In some applications, it may be preferable to have suction/

discharge ports rotated 90° (Figure 22) to be in-line with the

pump wheels. Perform the following procedure to rotate ports:

1. Remove the four hex head cap screws, hex nuts, flat

washers and lock washers from the pump base.

2. Push pump well downwards to separate from pump

base.

3. Rotate pump well 90° clockwise so that driver is

positioned over top of discharge plate.

4. Align pump well, pump base, and diaphragm with each

other. Once all components have been properly aligned,

reinstall the four hex head cap screws, hex nuts, flat

and lock washers and tighten securely.

Figure 22. Suction/Discharge Port Rotation

Clearing a Jam-Up

If large solids or an accumulation of sand, silt or other

sediment gather and become lodged in the pump well, the

plunger arm may be prevented from making a normal full

stroke. This action may cause the pump to stall, the crank

to slip on the output shaft, and ultimately cause damage to

the plunger arm.

Similarly, large damaging solids and debris may build in the

pump well and if not removed, may cause extreme damage

to the plunger arm and pump casing. If a jam or suspected

debris build-up occurs, the pump must be thoroughly cleaned

as described in the “Stalled/Stopped/Damaging Debris”

Section.

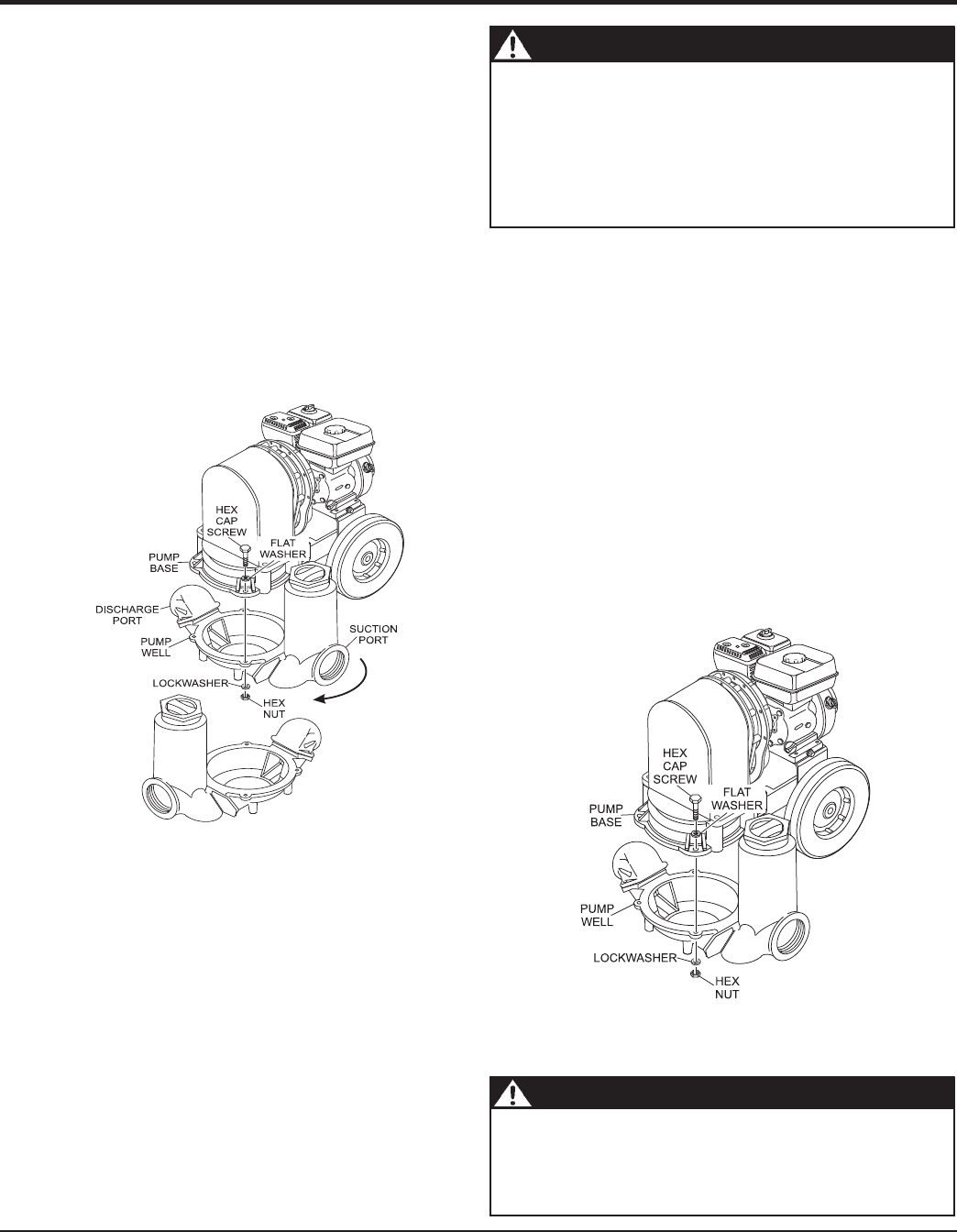

Stalled/Stopped/Damaging Debris

If Pump has stalled, stopped, or has been engaged in moving

heavy debris laden fluids, perform the following procedures:

1. Remove handle from pump. See Figure 6.

2. Remove the four hex head cap screws, hex nuts, flat

washers and lock washers from the pump base.

3. Push pump well downwards (Figure 23) to separate from

pump base.

4. Clean and remove all dirt and debris from pump well.

5. Align pump well, pump base, and diaphragm with each

other. Once all components have been properly aligned,

reinstall the four hex head cap screws, hex nuts, flat

and lock washers and tighten securely.

Figure 23. Pump Well (Clean-out)

During the course of pumping operations that include

heavy debris laden fluids, the pump well MUST be

checked for build-up of rocks, silt, sand and general de-

bris. Failure to clean out the pump cavity (well) could

result in damage to the plunger arm, and pump casing.

CAUTION - Stalled or Stopped Pump

MAINTENANCE

Pump jamming with an over-torqued lock screw (plunger

arm) may cause internal damage. Under torqueing may

allow the output shaft to spin and wear parts prematurely

causing replacement.

WARNING - Lock Screw Torqueing