MQD2H/3H DIAPHRAGM PUMPS — OPERATION AND PARTS MANUAL — REV. #7 (05/24/13) — PAGE 17

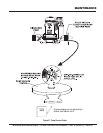

Gear Reduction Oil (Transmission)

1. Remove the transmission oil level plug (Figure 7). If oil

begins to seep out as the plug is being removed, then it

can be assumed that the transmission oil is at the proper

operating level.

2. If oil does not seep out as the oil level plug is being removed,

then remove the transmission oil fill plug and fill with SAE

80/90

EP (API GL-5) gear oil

to the proper operating level.

Transmission oil capacity is capacity is 22 ounces (651 ml).

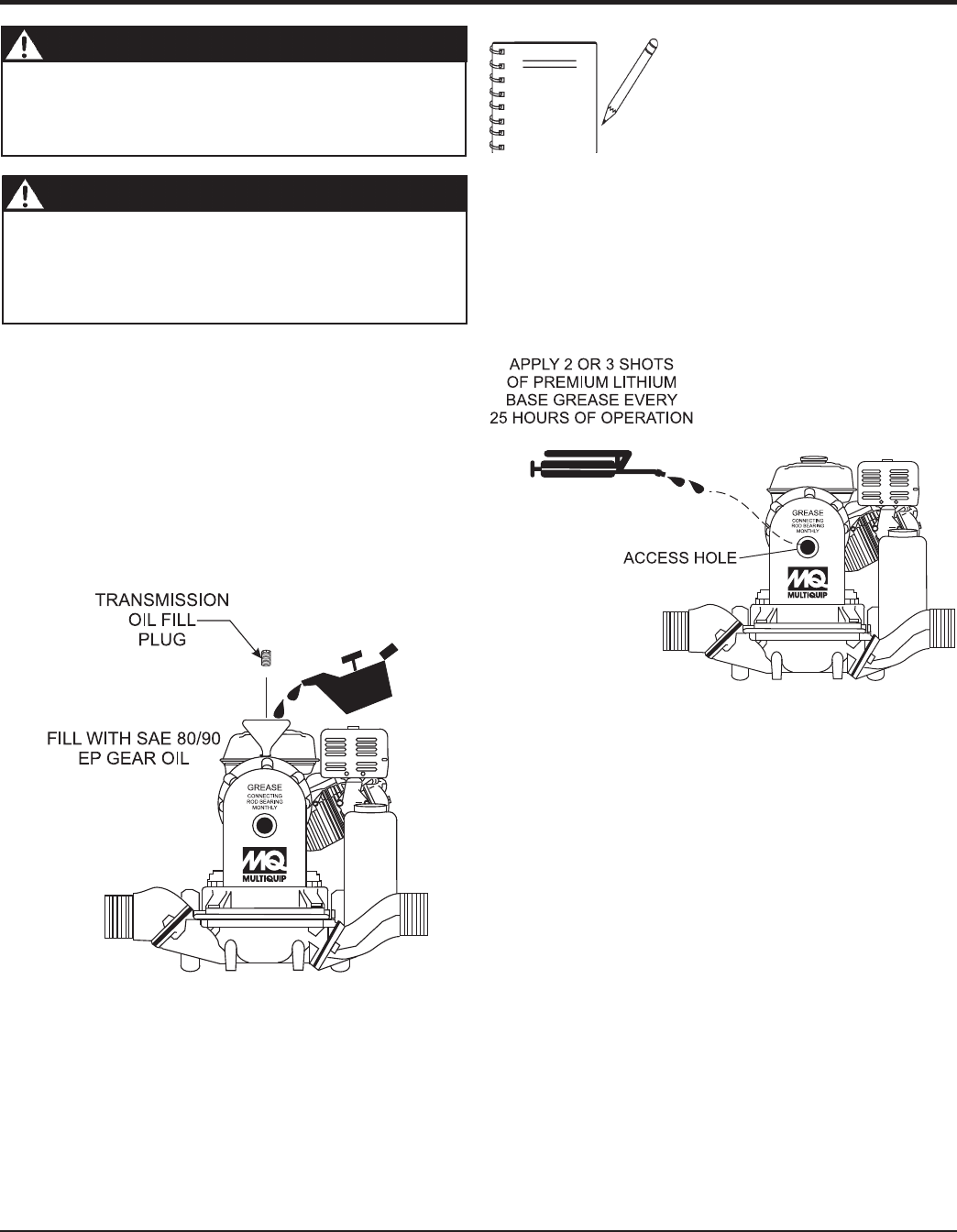

Connecting Rod Bearing Lubrication

1. Grease connecting rod bearing thru the access

hole (Figure 8) every 25 hours of operation.

2. Use only

premium lithium based grease

, conforming to

NLG1 Grade #2 consistency.

Figure 7. Transmission Oil Level

Figure 8. Connecting Rod Bearing Lubrication

Helpful Hints

The capacity of this diaphragm pump will vary greatly depending on

the height of the suction lift and length of the discharge hose. A

discharge hose which is too small, long or high will cause the

following:

■

Excessive bulging of diaphragm on the down stroke.

■

Valves closing with a loud snap.

■

Rough operation.

■

Engine overloads and slow downs.

■

Reduced efficiency.

NOTE

Diaphragm pumps will handle fluids

containing considerable solids (see

Table 1 for maximum solids diameter),

however, if the mixture is too heavy to

be pumped, water must be added until

the mixture becomes sufficently fluid for

pumping.

CAUTION - Strainer

The strainer should be positioned so it will remain completely

under water

. Running the pump with the strainer above

water for long periods can damage the pump.

DO NOT pump flammable fluids, corrosive chemicals or fluids

containing toxic substances. These fluids can create potentially

dangerous health and environmental hazards. Contact local

authorities for assistance.

CAUTION - Flammable Fluids

SETUP