BRAKE MAINTENANCE

Before towing, check that the brake fluid reservoir is

maintained to at least half full. If not refill with DOT 3

brake fluid. Check complete system for any leaks and

repair as needed. Examine actuator for bent parts or

excessive wear. Straighten or replace any worn parts

as needed. Check to see that all mounting bolts and

fasteners are tight.

Excessive actuator travel (over one inch) is a sign that

the brakes need to be adjusted. Jack wheel/tire off of

the ground and rotate tire in the forward direction.

Remove access hole cover plate on the lower back

side of the backing plate and adjust the brakes until

drag is felt on the wheel when spinning in the forward

direction. Back off adjuster twenty clicks (notches) for

two-wheel brake systems and fifteen clicks (notches)

for four wheel brake systems. Adjust all wheels being

sure to rotate in the forward direction only when

adjusting to ensure proper adjustment.

ANY CORROSIVE

MATERIALS (SALTWATER, FERTILIZERS) ARE

DESTRUCTIVE TO METALS. TO PROPERLY

MAINTAIN THE LIFE OF THE BRAKE SYSTEM

FLUSHING WITH A HIGH-PRESSURE WATER

HOSE IS RECOMMENDED. AFTER WASHING BE

SURE TO GREASE ACTUATOR BEARINGS

(SLIDES) AND OIL ALL MOVING PARTS. AT THE

END OF THE SEASON IT IS RECOMMENDED

THAT THE BRAKE DRUMS BE REMOVED AND

CLEANED INSIDE. REPACK WHEEL BEARINGS

BEING CAREFUL NOT TO CONTAMINATE THE

BRAKE SYSTEM WITH GREASE. THIS WOULD

BE A GOOD TIME TO READJUST THE BRAKES

PER PREVIOUS INSTRUCTIONS.

BLEEDING OF BRAKES

Before bleeding brakes fill the system with DOT 3

hydraulic brake fluid. Using a vacuum type brake

bleeder (this type of brake bleeder is available at your

local automotive store) follow manufacturers

directions for bleeding.

Install bleeder hose on first wheel cylinder to be bled,

if tandem bleed rear axles first. Have loose end of

hose submerged in a glass container of brake fluid to

observe bubbling. By working the manual hand pump

you will draw the air out of the brake lines filling it with

fluid.

By loosening the bleeder screw located in the wheel

cylinder one turn the system is open to the

atmosphere through the passage drilled in the screw.

When the bubbling stops in the glass container close

the bleeder screw securely. Follow the same

procedure at each wheel cylinder being sure to

maintain the master cylinder fluid level at least one

half full of brake fluid. After all wheels are bled fill the

master cylinder to 3/8” below the full level.

Before using any equipment equipped with brakes the

operation of the brakes should be checked. During

travel attention should be paid to how the brakes are

functioning and any necessary adjustments should be

made. It will be necessary to check the brake lines

and brake linings for wear. Brake linings should be

replaced before the rivets or support plates come in

contact with the wheel drum. Make all necessary

maintenance before using equipment.

Tandem Trailer Page 13

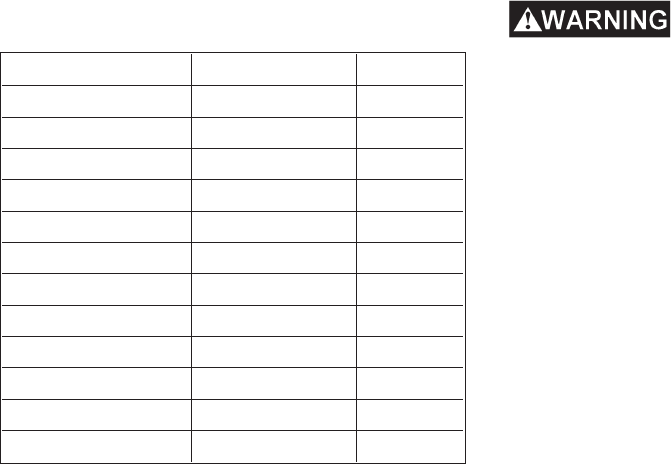

TIRE INFLATION

TIRE SIZE PLY PSI

11L-15 836

12.5L-15 836

12.5L-15 12 52

14L-16 12 44

16.5L-16 10 36

19LX16.1 10 32

21.5L-16.1 18 44

11R/22.5 used truck 75

425/65X22.5 used truck 75

28L-26 16 28

600/50X22.5 HS 16 52

600/50X22.5 I3 16 87