tread wear. By spacing the tire beads farther apart the

sidewalls are forced to flex in an area lower than

normal and this can result in circumferential carcass

breaks and/or separation.

USE OF A RIM NARROWER THAN

RECOMMENDED

This condition brings potential mounting problems

because the rim shield or flange cover molded into

most drive tire designs tends to interfere with the

seating of the tire beads on a narrow rim. Once

mounted on a narrow rim, the tire shield applies undue

pressure on the rim flange, with possible tire sidewall

separation or premature rim failure at the heel radius.

On a narrow rim the tread of the tire is rounded. As

with the over-inflated tire tread wear will be

concentrated in the center area of the tread and

traction in the field will be reduced.

ROADING OF FARM TIRES

Tractor tires operate most of the time in field

conditions where the lugs can penetrate the soil, and

where all portions of the tread make contact with the

ground. In operating on hard roads with low inflation

pressure there is an undesirable distortion of the tire

during which the tread bars squirm excessively while

going under and coming out from under the load. On

highly abrasive or hard surfaces, this action wipes off

the rubber of the tread bars or lugs and wears them

down prematurely and irregularly.

If tires are to operate for any length of time on roads or

other hard surfaces and the draft load is not great, it is

advisable to increase the pressure in the tire to the

maximum recommendation in order to reduce the

movement of the tread bars that causes excessive

wiping action.

Farm tractor and implement tires are designed for

low-speed operations not exceeding 25 miles per

hour. If tractors or implements are towed at high

speeds on the highway high temperatures may

develop under the tread bars and weaken the rubber

material and cord fabric. There may be no visible

evidence of damage at the time. Later a premature

failure occurs which experience shows was started by

the overheated condition that developed when the

unit was towed at a high speed.

CARE AND STORAGE OF TRACTOR AND

IMPLEMENT TIRES

All tires should be stored indoors in a cool, dark, dry

area free from drafts. Both heat and light are sources

of oxidation on the tire surfaces—a result of which is

crazing and weather checking. Tires should never be

stored on oily floors or otherwise in contact with

solvents, oil or grease. Further, tires should not be

stored in the same area with volatile solvents. Such

solvents are readily absorbed by rubber and will

damage and weaken it.

Tires should be stored away from electric motors,

generators, arc welders, etc.. since these are active

sources of ozone. Ozone attacks rubber—to cause

crazing and weather checking.

Unmounted tires should be stored vertically on tread.

If stored for an extended period, tires should be

rotated periodically to reduce stress concentrations in

the area of ground contact. Tires should not be stored

flat and “stove piped” as they will become squashed

and distorted, making mounting on the rim

difficult—particularly for tubeless tires.

Inflated tires mounted on rims should be stored under

conditions noted above, with inflation pressure

reduced to 10 PSI.

Tandem Trailer Page 12

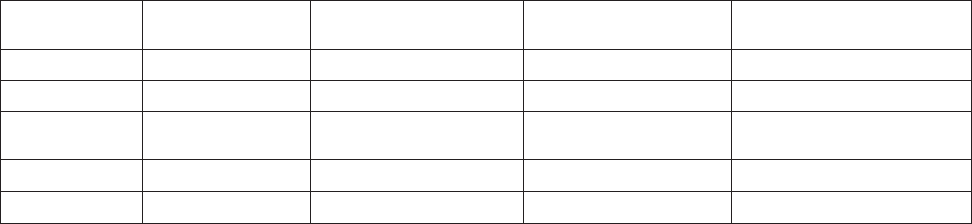

MEYER EQUIPMENT WHEEL TORQUE

BOLT/STUD

SIZE”

“SOCKET SIZE” “PRESS FORMED

WHEEL CENTER”

“BOLT TYPE” “HEAVY DUTY WHEEL

CENTER”

1/2 3/4 80 ft lbs Lug Bolt 85 ft lbs

9/16 7/8 80 ft lbs Lug Bolt 120 ft lbs

5/8 15/16

1-1/16

100 ft lbs “Bevel or Flange

Nut”

160 ft lbs

3/4 1-1/8 / 1-1/2 NA Flange Nut 378 ft lbs

22MM 32MM NA Flange Nut 450-500 ft lbs