34

•

Nitro 4-Tec 3.3

Adjusting Your Nitro 4-Tec 3.3

At no time should the

body of the car strike the

ground or interfere with

the suspension or tires.

Either situation will

cause extremely

unpredictable handling.

Toe In

Set the steering trim on your transmitter to neutral. Now, adjust your

tie rods so that both wheels are pointing straight ahead and are

parallel to each other (0 degrees toe in). This will ensure the same

amount of steering in both directions. If you run out of adjustment,

then the steering servo will have to be re-centered (see centering your

servos on page 35).

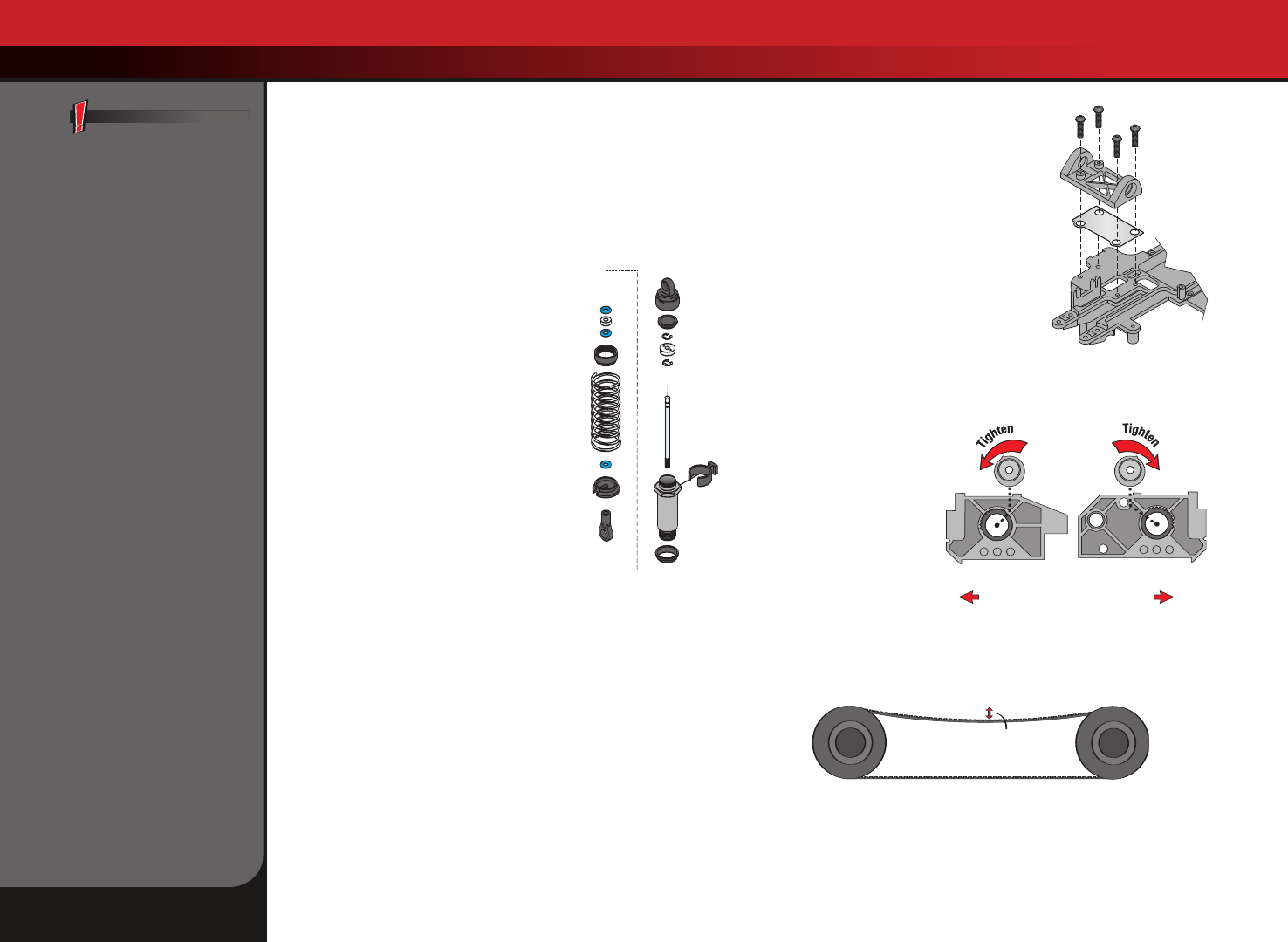

Fine Tuning the Shocks

The four shocks on your Nitro 4-Tec have the

most influence on its handling. Whenever you

rebuild your shocks, or make any changes to

the pistons, springs or oil, always do it

carefully and in pairs (front or rear). Piston

head selection depends on the range of oil

viscosities that you have available. For

example, using a one-hole piston with a

lightweight oil will give you the same

dampening as a two-hole piston with heavier

oil. We recommend using the one-hole

pistons with a range of oil viscosities from

10W to 50W (available from your hobby

shop). The thinner viscosity oils (30W or less)

flow more smoothly and are more consistent,

while thicker oils provide more dampening.

Use only 100% pure silicone shock oil to prolong seal life.

The ride height for Nitro 4-Tec can be adjusted by adding or removing

the clip-on spring pre-load spacers. Instead of adding spacers to

increase stiffness, use stiffer springs. Adjust the ride height so that the

suspension arms are slightly above being parallel to the ground. Note

that changes in ride height will occur when the changes in damper

angle or spring rates are made. You can compensate for ride height

changes by changing the pre-load spacers on the dampers. Generally

speaking, ride height should be set as low as possible without causing

significant bottoming of the chassis. Also, in order not to disturb

cornering balance, front and rear tire height diameters should be

equal. Replace excessively worn tires.

Belt Tension Adjustments

The Nitro 4-Tec’s front and middle drive

belts are designed to have a high initial

tension. During the break-in period, the

drive belts and pulleys will “wear in” and

the belt tension will gradually decrease.

The front and middle belt tensions can be

tightened by inserting shims under the

front bearing block. Do not tighten the

front belt tension unless there is more

than 0.25 inch (6mm) deflection at the

center of the belt (see drawing). To

tighten the belt, add the 0.1mm shim first

and retest. If the belt is still loose, remove

the 0.1mm shim and add the 0.2mm shim

and retest.

The rear belt tension is

adjustable via belt tension

cams in the right and left

rear side plates. The rear

belt in the Nitro 4-Tec

transmits most of the

engine’s power. Because of

the high loading of the rear

belt, the tension should be

checked every 3-4 hours

(20-25 tanks of fuel) of running. If the rear belt can be deflected more

than 0.25¨ (6mm) (see illustration), the belt tension cams should be

rotated rearward to the next eccentric slot.

Left side plate

(Bulkhead)

Right side plate

(Bulkhead)

Rear of car Rear of car

.25¨ (6mm)

Using Belt

Adjustment Shims