MAINTENANCE WORK ON CHASSIS AND ENGINE »

ENGLISH

48

3

4

5

6

7

8

9

10

11

12

13

15

14

28

20

22

21

23

24

25

26

29

30

27

A

B

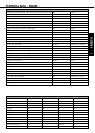

Draining the float chamber of the carburetor

Following every wet cleaning procedure, the float chamber of the carburetor

should be drained in order to remove any water that may have penetrated into

it. Water in the float chamber causes malfunctioning. Perform this task on a

cold engine.

400/450/525: Close the fuel tap and put one end of the hose [1] into a col-

lecting vessel. Open the drain plug [2a] (turning it counterclockwise) by ser-

val turns, and drain the fuel from the float chamber. Then, retighten the drain

plug and open the fuel tap.

250-F: Close the fuel tap, and place a cloth under the carburetor, which is

capable of absorbing the leaking fuel. Unscrew the plug [2b] and clean it with

compressed air. Then, mount the plug together with the gasket, open the fuel

tap, and check the float chamber for leaks.

– Fuel is easily flammable and toxic. When handling fuel, be sure to exer-

cise the utmost caution. Never perform any work on the fuel system near

open flames or burning cigarettes.

– Always allow the engine to cool off first. Immediately clean up any fuel

which may have been spilled. Materials saturated with fuel are also eas-

ily flammable. In case you ingested fuel or fuel splashed into your eyes,

consult a doctor immediately.

– Dispose of the fuel properly.

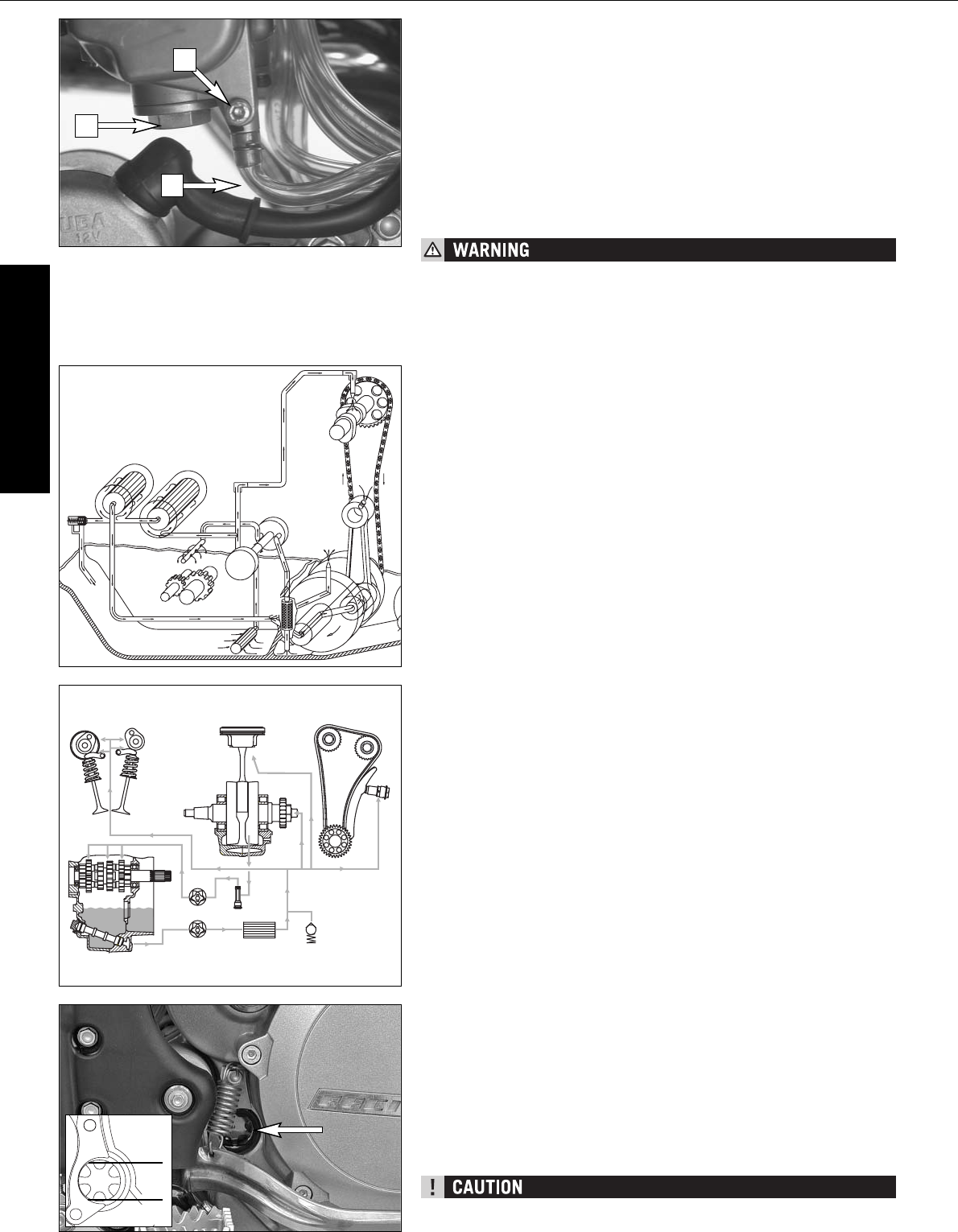

Oil circuit (400/450/525)

Via the long oil screen [4], the oil pump [3] draws engine oil from the oil sump

of the transmission. This engine oil flows through an oil line [5] into the cylin-

der head for camshaft lubrication [6]; the oil quantity is controlled by the jet

screw [7]. An oil duct branches off to the long oil filter [8] where the coarser

particles contained in the engine oil are filtered away. Then, the engine oil

arrives at the short oil filter [9] which also filters the fine particles. Now, the

purified engine oil is pumped past the bypass valve [10] to the conrod bear-

ing [11] and sprayed from below onto the piston through a nozzle [12].

The second oil pump [13] draws the engine oil via the short oil screen [14]

out of the crankcase, thereby lubricating the transmission gears [15].

Oil circuit (250-F)

The oil pump [20] sucks engine oil from the transmission oil sump through

the long oil screen [21] and conveys it to the oil filter [22] where any con-

tamination is filtered out. The cleaned engine oil is pumped past the bypass

valve [23] to the conrod bearing [24] and sprayed onto the pistons from below

through a jet [25].

Two other oil ducts lead into the cylinder head. One duct supplies the hydraulic

chain tensioner [26], the other duct leads to the camshaft bearing support

[27], where the camshaft bearings and the cam lever are supplied with oil

(via spraying nozzles).

The second oil pump [28] sucks the engine oil out of the crankcase through

the short oil screen [29] and uses it to grease the transmission gears [30].

Checking the engine oil level

The engine oil level can be checked with the engine either warm or cold. Place

the motorcycle in an upright position and on a horizontal surface (not on the

side stand).

If the engine is cold, the engine oil must be visible at the lower edge of the

inspection glass [A].

If the engine is warm, the engine oil must be visible up to the upper edge of

the inspection glass [B].

Replenish the engine oil, if necessary.

Insufficient amounts of or low-grade engine oil lead to premature wear in the

engine.

2a

1

2b