ENGLISH

15

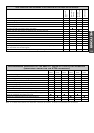

VITAL CHECKS AND CARE PROCEDURES TO BE CONDUCTED BY THE OWNER OR THE MECHANIC

Check transmission oil level ●

Check cooling liquid level ●

Check brake fluid level ●

Check brake pads for wear ●

Check brake performance ●●

Lubricate and adjust actuating cables and nipples ●

Remove and clean dust sleeves of telescopic fork at regular intervals ●

Clean and lubricate chain, check tension and readjust it if necessary ●●

Clean air filter and filter box ●

Check tire inflation pressure and wear ●

Check fuel line for leaks ●

Drain and clean float chamber ●

Verify smooth operation of all controls ●

Treat exposed metal components (except for the brake and exhaust systems) ●

with wax-based anti-corrosion agents

Check all screws, nuts, and hose clamps for their tight fit at regular intervals ●

for cross

country use

once a year

after every

cleaning

before each

start

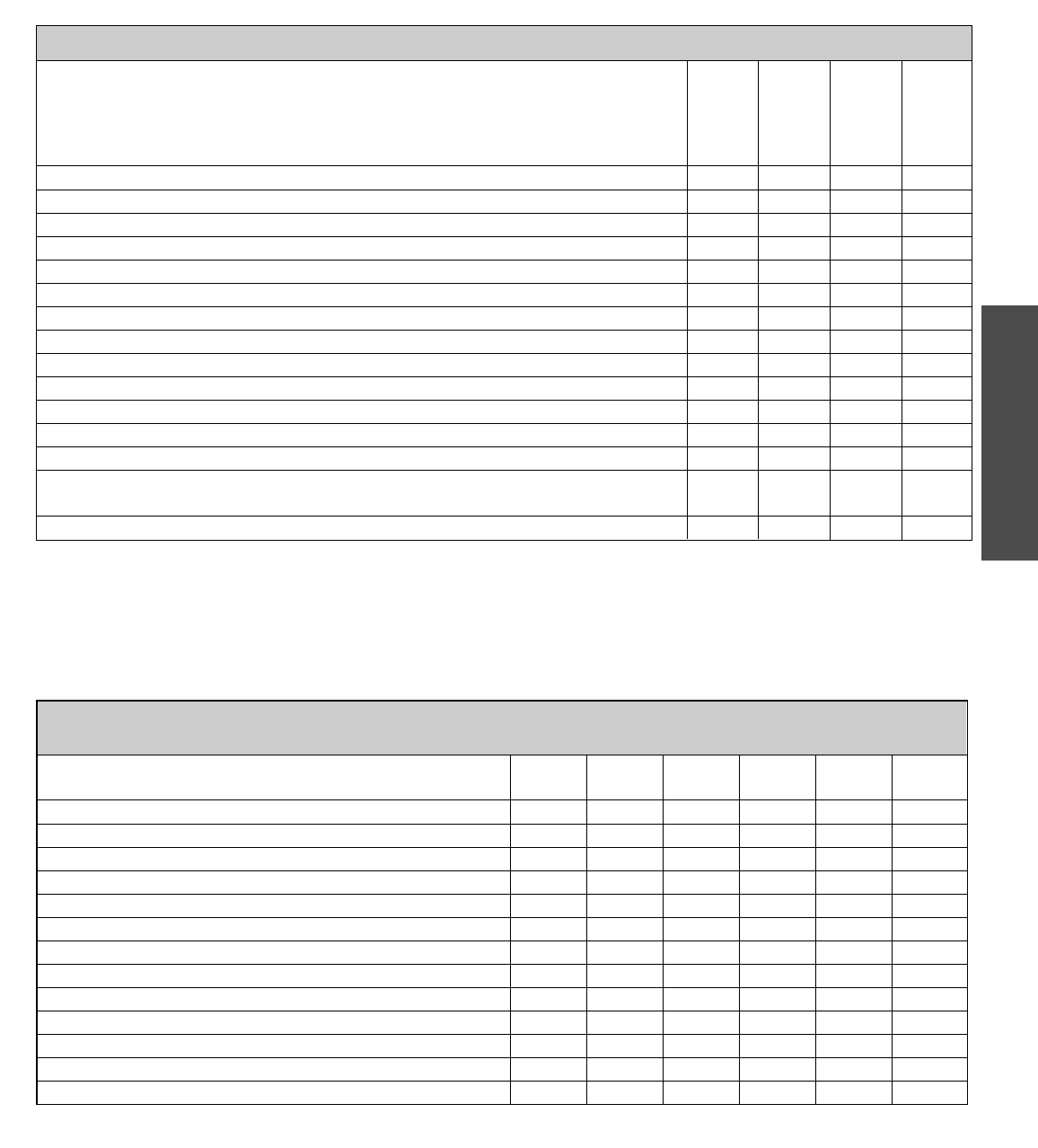

RECOMMENDED INSPECTION OF THE MINI LC ENGINE BY YOUR KTM WORKSHOP

(ADDITIONAL ORDER FOR THE KTM WORKSHOP)

Check the reed-type intake valve for wear ●●●●●●

Check the clutch shoes for wear ●●●●●●

Check the length of the clutch springs ●●●●●●

Check the clutch drum for wear ●●●●●●

Check the water pump shaft and bearings for wear ●●●●●●

Check the water pump wheel for wear ●●●●●●

Check the cylinder and piston for wear ●●●●●●

Check the eccentricity of the crankshaft journal ●●●●●●

Check the radial clearance of the conrod bearings ●●●

Check the radial clearance of the piston pin main bearing ●●●

Check the crankshaft main bearing for wear ●●●

Replace the crankshaft bearings and conrod bearings ●●●

Check the entire transmission including bearings for wear ●●●

30

hours

45

hours

60

hours

90

hours

120

hours

135

hours

NOTE: IFTHE INSPECTION ESTABLISHES THAT PERMISSIBLE TOLERANCES ARE EXCEEDED, THE RESPECTIVE COMPONENTS MUST BE REPLACED.