Batteries – Electric Vehicles

2005 Husqvarna 4210-G, 4210-E, 4210-GXP, and 4210-EXP Owner’s Manual Page 35

BATTERY CARE

To keep batteries in good working condition, follow this maintenance program on a regular basis:

1. The batteries should be kept clean and free of corrosion. Wash tops and terminals of batteries with a solu-

tion of baking soda and water (1 cup (237 mL) baking soda per gallon (3.8 L) of water). Rinse solution off

of the batteries. Do not allow this solution to enter the battery. Be sure terminals are tight. Let the terminals

dry and then coat with Battery Terminal Protector Spray (Husqvarna 603 00 00-03). See following NOTE.

NOTE: Dispose of waste water properly.

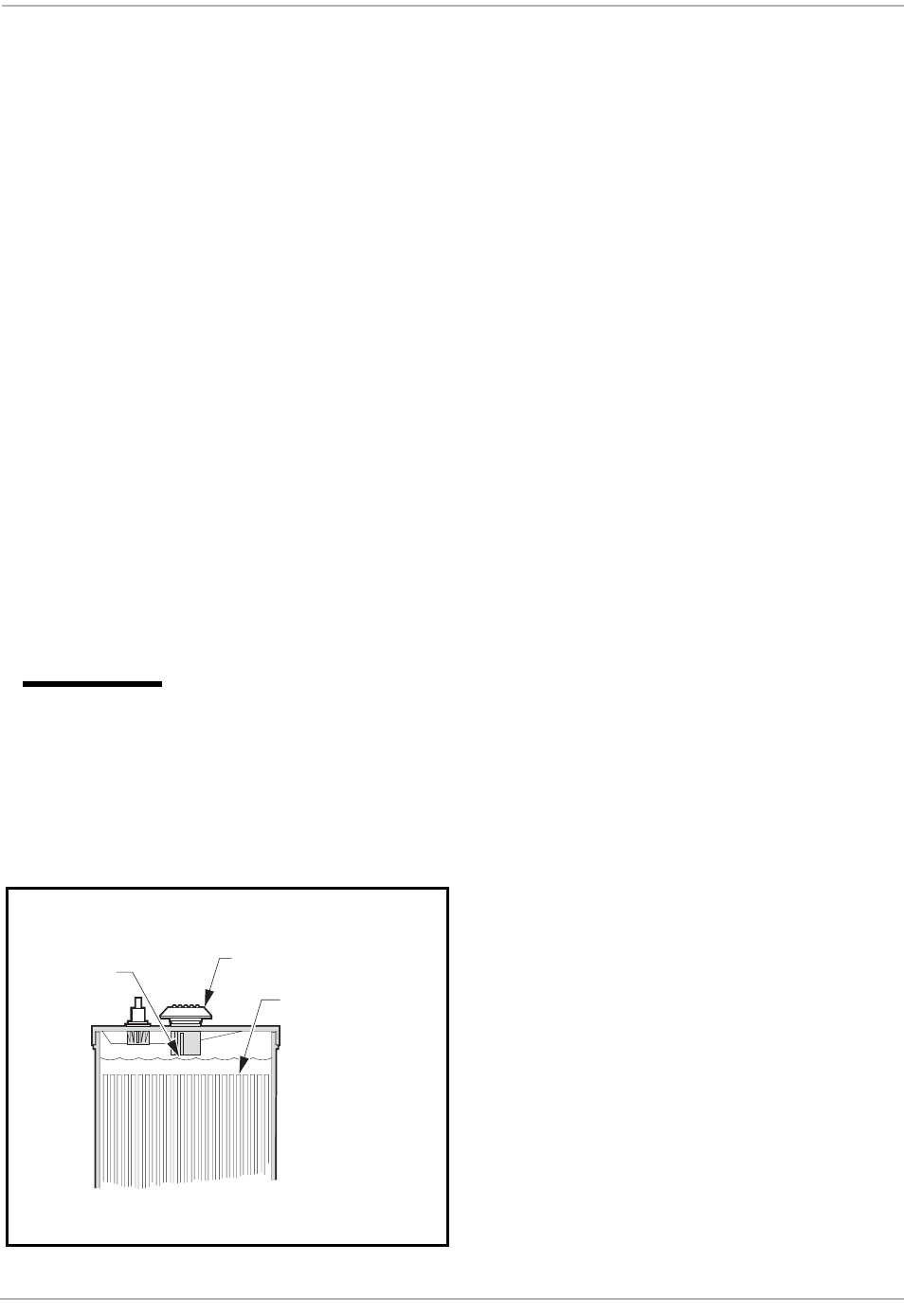

2. The electrolyte level in the batteries should be checked weekly (Figure 21). Add water only after charg-

ing unless the electrolyte level is below the top of the plates. In this case, add just enough water to cover

the plates, charge and then check the level again. Never charge batteries if plates are exposed above

electrolyte level. For best battery life, add only distilled water. See following NOTE.

NOTE: A battery watering gun or bottle is available at many auto parts dealers.

3. The hold-down straps should be tight enough so that the batteries do not move while the vehicle is in

motion, but not so tight as to crack or buckle the battery case. Tighten hold-down retaining nuts to 40 in-

lb (4.5 N·m). The terminal connections should be clean and tight, and any worn insulation or frayed wires

should be replaced. Tighten battery terminals to 110 in-lb (12.4 N·m). See following CAUTION.

ý CAUTION

• If battery wire terminals are damaged or corroded, they should be replaced or cleaned as

necessary. Failure to do so may cause them to overheat during operation.

4. After use, the batteries should be placed on charge. The batteries should never be left discharged any

longer than absolutely necessary (do not leave discharged overnight).

Figure 21 Electric Battery Electrolyte Level

ELECTROLYTE

LEVEL AT LEAST

1/2 INCH (13 MM)

ABOVE PLATES

OR TO LEVEL

INDICATOR

PLATES

LEVEL

INDICATOR

BATTERY CAP